Substrate processing equipment

A substrate processing device and substrate technology, applied in the direction of conveyor control devices, transportation and packaging, electrical components, etc., can solve the problems of wrong detection of substrates, poor substrate transmission efficiency, and inability to transmit detection, so as to prevent false detection and realize processing Efficiency, the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

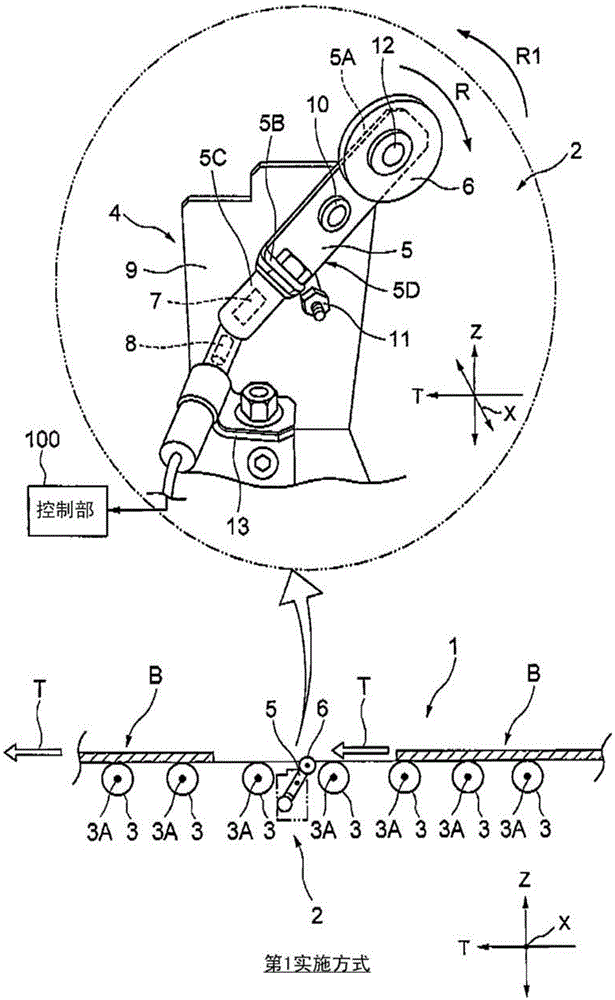

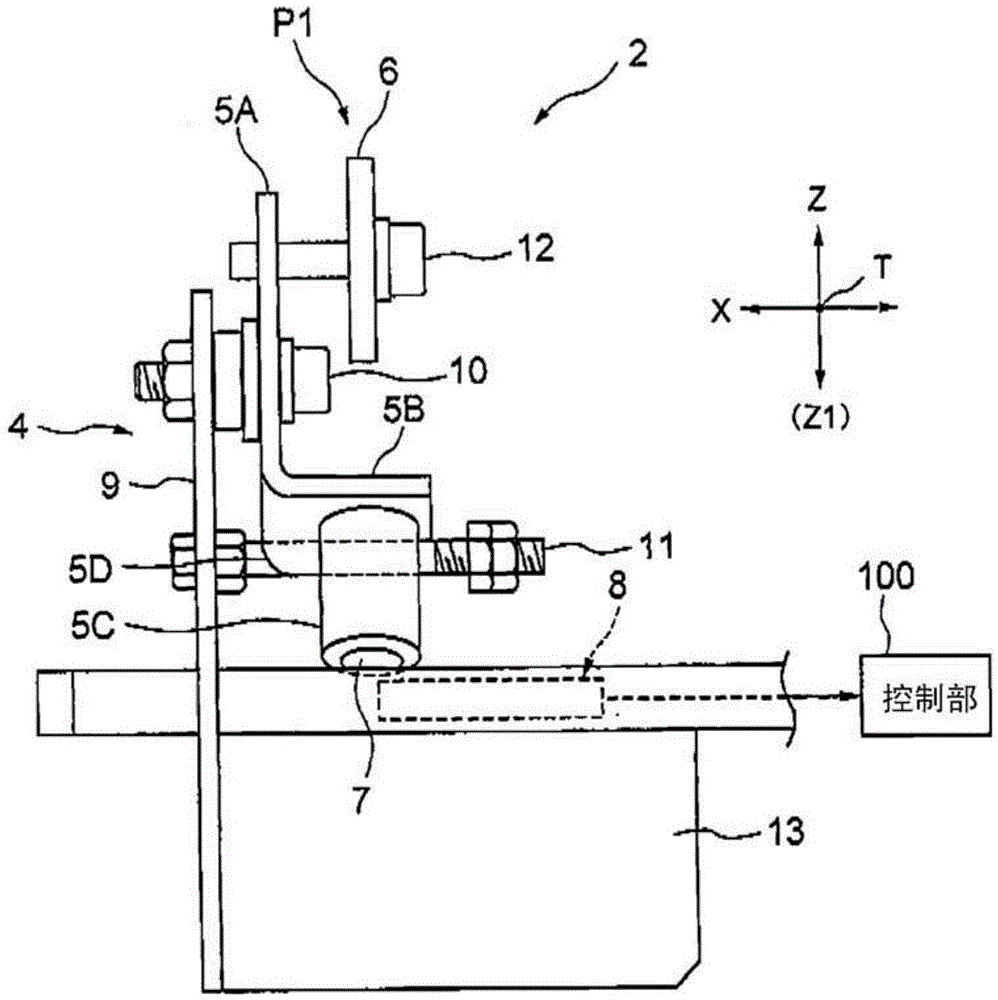

[0019] figure 1 It is a figure which shows the preferable 1st Embodiment of the substrate processing apparatus of this invention. figure 2 yes means figure 1 It is a diagram showing a configuration example and an operation example of the substrate inspection device 2 installed in the substrate processing apparatus shown.

[0020] Such as figure 1 As shown, in the embodiment of the present invention, as an example of a substrate processing apparatus, a substrate to be processed, such as a glass substrate B (hereinafter referred to as a substrate) for a liquid crystal display device, is conveyed along the conveying direction T, and the The cleaning treatment liquid is supplied to the front and back sides, and the stains on the surface of the substrate B are cleaned. As the cleaning treatment liquid, for example, pure water is used, but not limited thereto.

[0021] figure 1 The substrate processing apparatus 1 illustrated in FIG. 1 includes a substrate detection device 2 ,...

no. 2 Embodiment approach

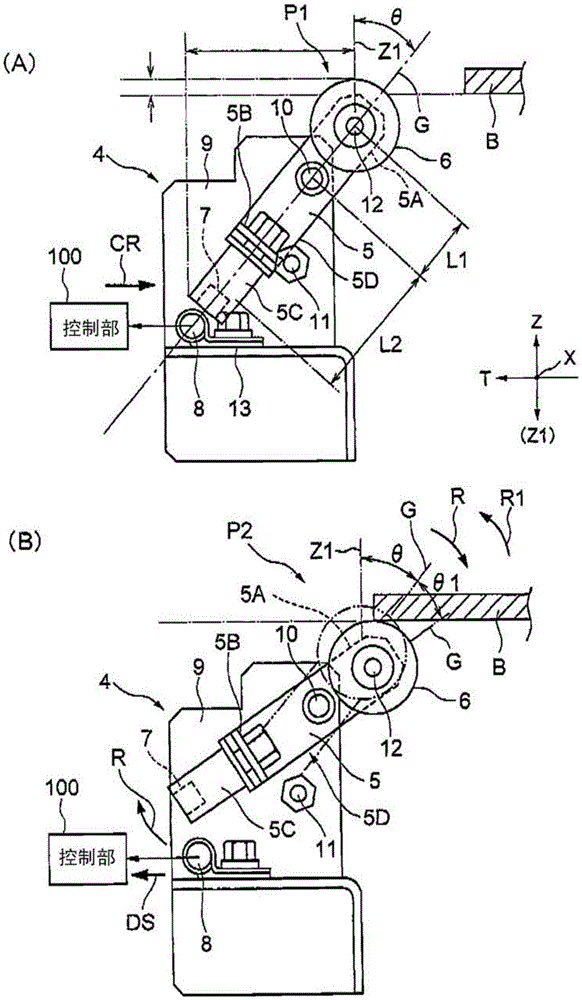

[0046] Next, a preferred second embodiment of the substrate processing apparatus of the present invention will be described.

[0047] Figure 7 (A) is a front view showing the substrate detection device 102 included in the substrate processing device according to the second embodiment of the present invention, Figure 7 (B) is viewed from the arrow HJ Figure 7 (A) is a side view of the substrate processing apparatus 102 shown.

[0048] The substrate detection device 102 is also referred to as a substrate presence / absence detection device. The substrate inspection device 102 is set, for example, at figure 1 Between the conveyance roller 3 of the several conveyance roller 3 of the shown substrate processing apparatus 1, two adjacent conveyance rollers 3 are shown. Such as Figure 7(A) and Figure 7 As shown in (B), the substrate detection device 102 has a base 104, a swing member 105, a counterweight 105C, an additional counterweight 105D, a detection roller 106, a magnet...

no. 3 Embodiment approach

[0059] Next, a preferred third embodiment of the substrate processing apparatus of the present invention will be described.

[0060] Figure 8 It is a front view showing the substrate inspection device 202 included in the substrate processing apparatus according to the third embodiment of the present invention. Figure 8 The structure of the substrate detection device 202 shown is the same as Figure 7 (A) and Figure 7 The substrate inspection device 102 shown in (B) has substantially the same configuration, but has the following differences.

[0061] Such as Figure 8 As shown, there are base 104, swing member 105, counterweight 105C, forcing counterweight 105D, detection roller 106, magnet 107, detection sensor 108 such as reed switch, swing fulcrum member 110 and swing stopper 111. The swing member 105 has the Figure 7 The first portion 105S formed along the vertical line Z1 in the Z direction and the second portion 105T formed along the inclined line V in a state po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com