A preparation method of graphite fluoride and lithium manganate composite material and preparation of lithium ion battery as positive electrode material

A technology of ink, lithium manganate and lithium ion batteries, which is applied in the field of lithium battery cathode materials, can solve the problems of battery capacity attenuation, slow dissolution, material lattice change, etc., and achieves improved electrical conductivity, improved cycle performance, high gram The effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Concentration of 10% hydrofluoric acid and fluorinated graphite with 20% fluorine content are mixed according to the ratio of 1:10, ultrasonic cleaning for 1 hour, suction filtration, and drying in an oven at 200°C for 2 hours. The mass ratio of graphite fluoride to lithium manganate is 1:8 and mixed in a fusion spheroidizer. The temperature of the fusion spheroidizer is 150° C., the rotation speed is 900 Hz, and the mixture is fused for 2 hours. The fused composite material is iron-removed and sieved to obtain graphite fluoride composite lithium manganate cathode material.

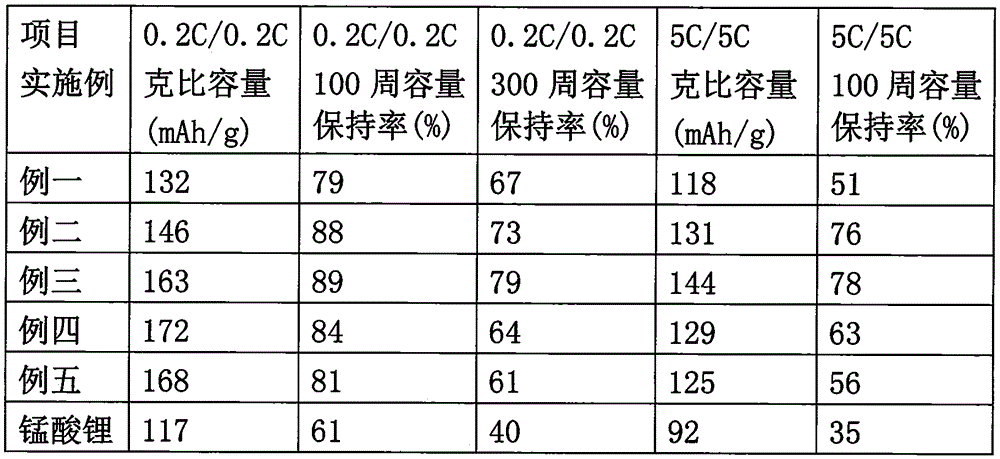

[0019] Add conductive carbon black and PVDF to the composite material, and coat it on aluminum foil to make a positive electrode sheet, and make a lithium battery with graphite negative electrode and electrolyte. Under the environmental condition of 20±5℃, the constant current charge and discharge test was carried out on the battery in the range of 3.0~4.2V. The specific results are shown in the ta...

Embodiment 2

[0021] Concentration of 10% hydrofluoric acid and 30% fluorine graphite fluoride, mixed according to the ratio of 1:10, ultrasonic cleaning for 1 hour, after suction filtration, placed in an oven at 200 ° C for 2 hours. Graphite fluoride and lithium manganate with a mass ratio of 1:8 were added to a fusion spheroidizer for mixing. The temperature of the fusion spheroidizer was 150° C. and the rotation speed was 800 Hz, and the mixture was fused for 2 hours. The fused composite material is iron-removed and sieved to obtain graphite fluoride composite lithium manganate cathode material.

[0022] Add conductive carbon black and PVDF to the composite material, and coat it on aluminum foil to make a positive electrode sheet, and make a lithium battery with graphite negative electrode and electrolyte. Under the environmental condition of 20±5℃, the constant current charge and discharge test was carried out on the battery in the range of 3.0~4.2V. The specific results are shown in th...

Embodiment 3

[0024] Concentration of 10% hydrofluoric acid and 30% fluorine graphite fluoride, mixed according to the ratio of 1:10, ultrasonic cleaning for 1 hour, after suction filtration, placed in an oven at 200 ° C for 2 hours. The mass ratio of graphite fluoride to lithium manganate is 1:15 and mixed in a fusion spheroidizer. The temperature of the fusion spheroidizer is 150° C., the rotation speed is 800 Hz, and the mixture is fused for 2 hours. The fused composite material is iron-removed and sieved to obtain graphite fluoride composite lithium manganate cathode material.

[0025] Add conductive carbon black and PVDF to the composite material, and coat it on aluminum foil to make a positive electrode sheet, and make a lithium battery with graphite negative electrode and electrolyte. Under the environmental condition of 20±5℃, the constant current charge and discharge test was carried out on the battery in the range of 3.0~4.2V. The specific results are shown in the table below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com