A kind of preparation method of high capacity lithium ion battery negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low theoretical capacity of materials and inability to change the lithium storage structure of materials, so as to increase the gram specific capacity and improve cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

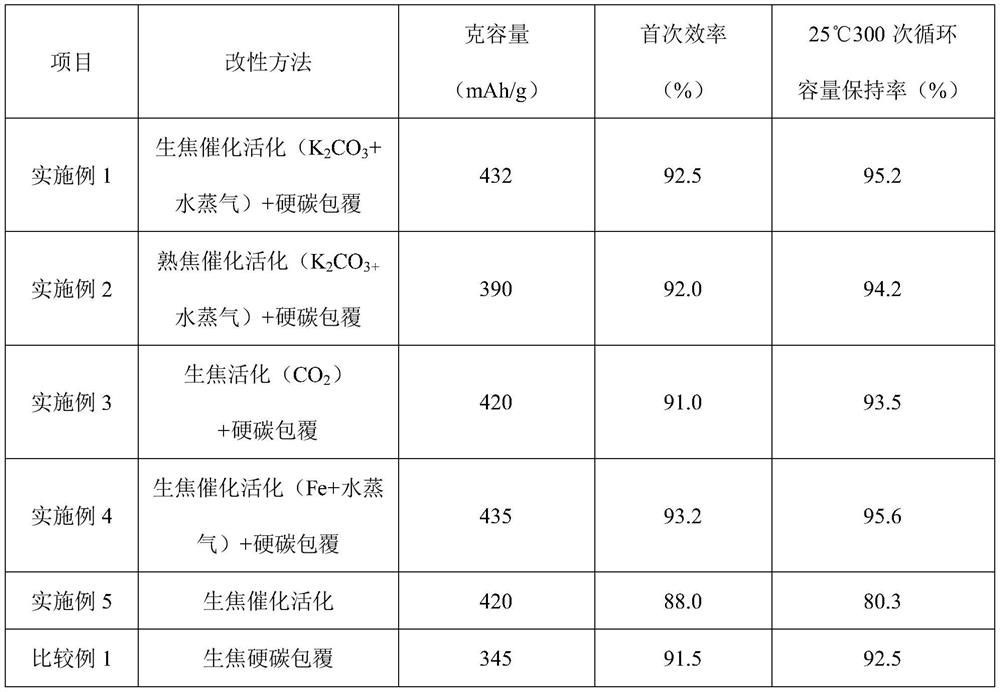

Examples

Embodiment 1

[0022] (1) pulverizing petroleum coke (green coke) to obtain particles with a particle size of 5 μm;

[0023] (2) heat treatment at 1100°C under inert atmosphere conditions of the obtained green coke powder, and then pulverized to 5 μm;

[0024] (3) in the presence of potassium carbonate, use an activator (steam) at 750° C. to treat the product of step (2) for 1 h;

[0025] (4) Mix 100 parts with 30 parts of phenolic resin, and carbonize at 1100 ℃ under an inert atmosphere;

[0026] (5) Heat treatment at 2000°C for 12h in an inert atmosphere, mix, sieve, and magnetically separate after cooling to obtain nano-scale micropores with a hard carbon protective layer.

Embodiment 2

[0028] (1) pulverize an appropriate amount of petroleum coke (cooked coke) to 25 μm;

[0029] (2) In the presence of potassium carbonate, the product of step (2) is treated at 800° C. with an activator (steam) for 14h;

[0030] (3) Mix 100 parts with 20 parts of phenolic resin, and carbonize at 1200°C under an inert atmosphere;

[0031] (4) Heat treatment at 2500°C for 36h in an inert atmosphere, mix, sieve, and magnetically separate after cooling to obtain nano-scale micropores with a hard carbon protective layer.

Embodiment 3

[0033] (1) pulverizing petroleum coke (green coke) to obtain particles with a particle size of 30 μm;

[0034] (2) heat treatment at 1300°C under inert atmosphere conditions of the obtained green coke powder, and then pulverized to 20 μm;

[0035] (3) 900 ℃ using activator (CO 2 ) the product of step (2) is treated for 18h;

[0036] (4) Mix 100 parts with 25 parts of phenolic resin, and carbonize at 1300 ℃ under an inert atmosphere;

[0037] (5) Heat treatment at 2800°C for 48h in an inert atmosphere, mix, sieve and magnetically separate after cooling to obtain nano-scale micropores with a hard carbon protective layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com