Method for preparing lithium battery negative electrode material from medium and low temperature coal tar and application of lithium battery negative electrode material

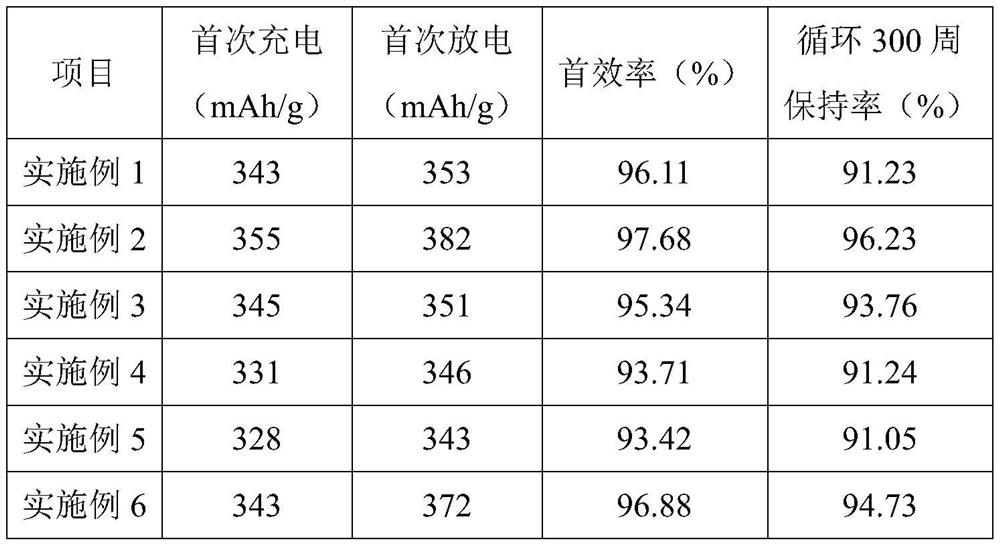

A low-temperature coal tar and negative electrode material technology, applied in lithium batteries, battery electrodes, negative electrodes, etc., can solve the problems of unfavorable carbon layer structure and evenly distributed voids, unsteady control of product quality, and poor carbon layer structure regularity. The preparation process is simple and feasible, the cycle performance is excellent, and the anti-attenuation ability is outstanding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation method provided by the invention, concrete steps are as follows:

[0038] 1) Raw material pretreatment

[0039] The medium and low temperature coal tar raw material is cut into fractions to obtain 350-520°C fractional asphalt;

[0040] 2) Separation and deployment

[0041]2.1) Use n-alkane solution, single-ring hydrocarbon aromatics solution and quinoline solution to extract and separate the 350-520°C fractional bitumen in step 1) three times in sequence, and obtain n-alkane soluble HS components, n-alkane insoluble single-ring aromatic hydrocarbon soluble HI-TS component and single-ring aromatic hydrocarbon insoluble quinoline soluble TI-QS component;

[0042] Specific separation methods include:

[0043] 2.1.1) Mix 350-520°C fractional asphalt with n-alkane solution, an extraction reaction occurs under stirring conditions, and stand to obtain a supernatant and a lower asphalt HI; from the supernatant, separate the normal Alkane solubles HS, lower bitum...

Embodiment 1

[0058] The method for preparing lithium battery negative electrode materials provided by this embodiment using medium and low temperature coal tar comprises the following steps:

[0059] 1) The medium and low temperature coal tar raw material is cut into fractions to obtain 350-520°C fractional asphalt;

[0060] 2.1) Separation and blending of asphalt in distillate section at 350~520℃

[0061] 2.1.1) Weigh 150g of 350~520℃ distillate bitumen, put it into a reaction kettle containing 300g of n-heptane solvent, first raise the temperature of the reaction kettle to 65℃, and stir for 10min at a speed of 1800r / min to generate An extraction reaction, and then stand still for 1 hour to obtain a supernatant liquid and a lower pitch HI; take out a supernatant liquid, and separate the n-heptane solvent to obtain n-heptane solubles HS; the lower pitch HI is taken out and dried for use;

[0062] 2.1.2) Put the lower bitumen HI in 2.1.1) into a reaction kettle filled with 300g of toluene ...

Embodiment 2

[0068] The method for preparing lithium battery negative electrode materials provided by this embodiment using medium and low temperature coal tar comprises the following steps:

[0069] 1) The medium and low temperature coal tar raw material is cut into fractions to obtain 350-520°C fractional asphalt;

[0070] 2.1) Separation and blending of asphalt in distillate section at 350~520℃

[0071] 2.1.1) Weigh 150g of 350-520°C distillate asphalt, put it into a reactor containing 300g of n-heptane solvent, raise the temperature of the reactor to 75°C, and then stir once every 30 minutes at 2000r / min. Extraction reaction, and then stand still for 1 hour to obtain a supernatant and a lower pitch TI; take out a supernatant, separate the n-heptane solvent to obtain n-heptane solubles HS; take out the lower pitch HI and dry it for later use;

[0072] 2.1.2) Put the lower pitch HI obtained in 2.1.1) into a reaction kettle filled with 300g of toluene solvent, first raise the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com