Battery equalizing charging method and equalizing charger thereof

A battery equalization and charging method technology, which is applied to battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of reduced charging speed, non-compliance with battery charging standards, and high cost, and achieve the effect of improving performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

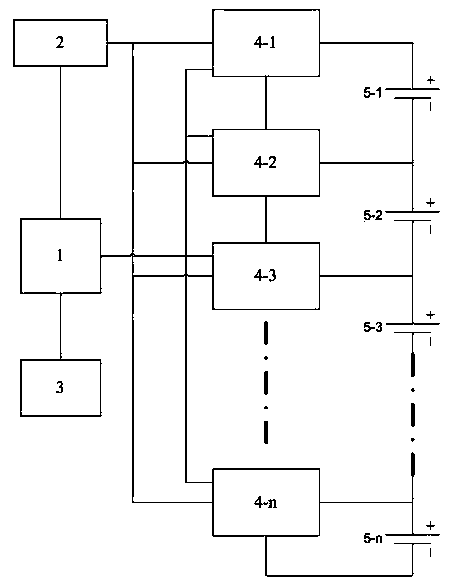

[0027] 1. Connect the equalizing charger to the single cell 1 (5-1) ~ single cell N (5-n) of the battery pack;

[0028] 2. Start the equalizing charger, and the power supply unit (2) provides the power required for the equipment to work;

[0029] 3. The controller unit (1) collects the voltage from the single cell 1 (5-1) to the single cell N (5-n) and displays it on the liquid crystal display module (3);

[0030] 4. Start the charging power supply 1 (4-1) ~ charging power supply N (4-n) corresponding to the single battery cell whose voltage is within the set range, and start the charging power supply 1 (5-1) ~ single battery cell N(5-n) for charging;

[0031] 5. The controller unit (1) performs timing. When the timing reaches the set time interval, it records the working status of the charging power source 1 (4-1) ~ charging power source N (4-n), and controls the charging power source 1 (4- 1) ~ Charging power supply N(4-n) stops working;

[0032] 6. The controller unit (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com