Electric kettle

An electric kettle and kettle body technology, applied in the field of electrical appliances, can solve the problems of high manufacturing precision and large space occupied by electric couplers, and achieve the effects of good contact, small size, easy processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 4 example

[0047] The fourth embodiment of the present invention is: the lower coupler base is designed into two mechanisms, the middle is a fixed lower coupler mechanism, and the periphery is a stable cover mechanism supported by elastic parts that can move up and down. The movement achieves the purpose of up and down compensation of the coupler.

no. 5 example

[0048] The fifth embodiment of the present invention is: embodiment 5: the bottom cover of the kettle body can be folded into two parts, the middle is the fixed upper coupler, the circumference is a separate floating part, called the bottom shell and the bottom shell There are elastic parts on the parts so that the shell of the kettle body can float up and down to achieve the purpose of compensation.

no. 1 example

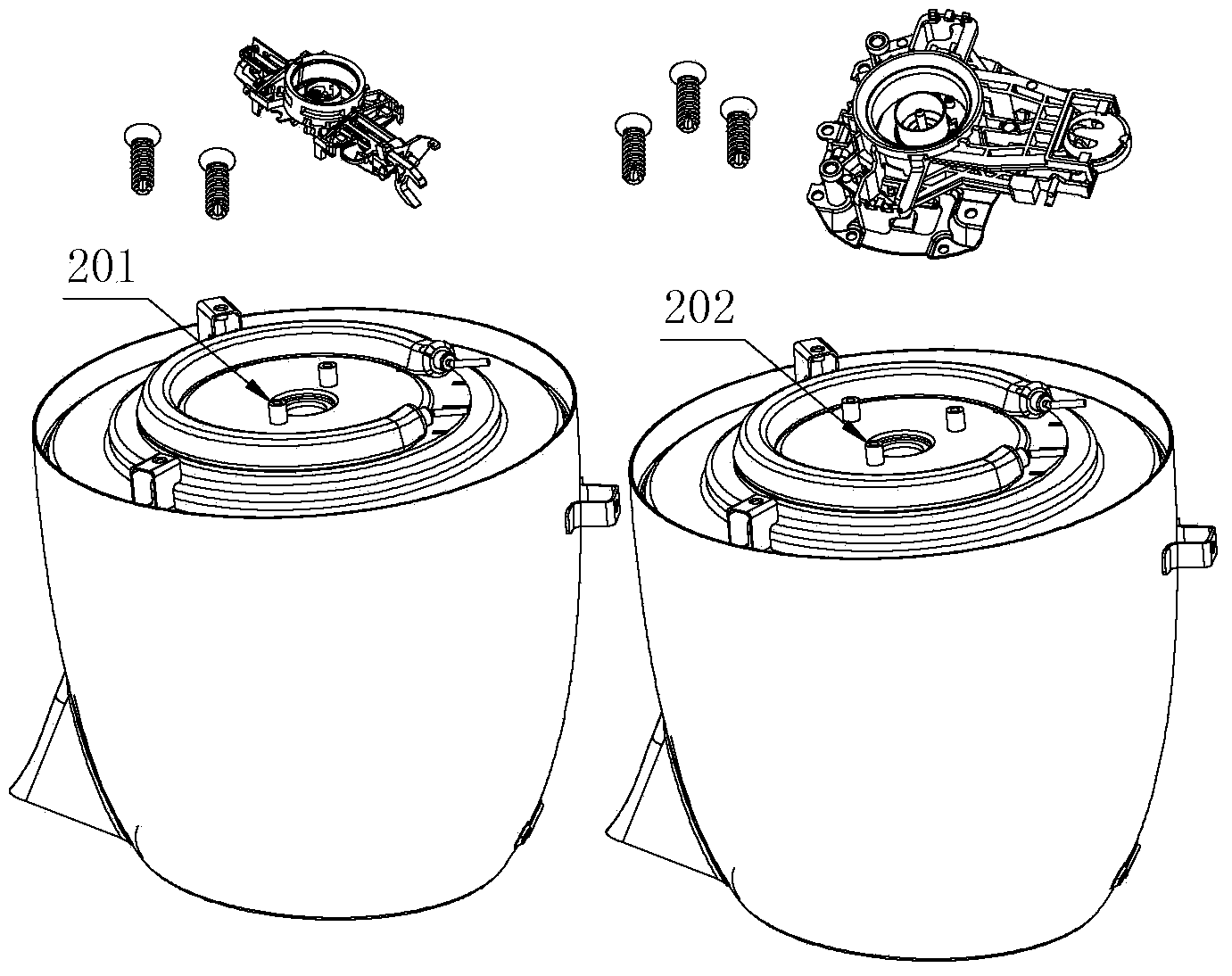

[0049] The following describes the first embodiment of the present invention: by improving the structure of the existing base, the elastic compensation structure is arranged between the upper and lower covers of the base.

[0050] Reference Figure 2 to Figure 4 As shown, the difference between the electric coupler of the present invention and the electric coupler of the prior art is specifically described as follows:

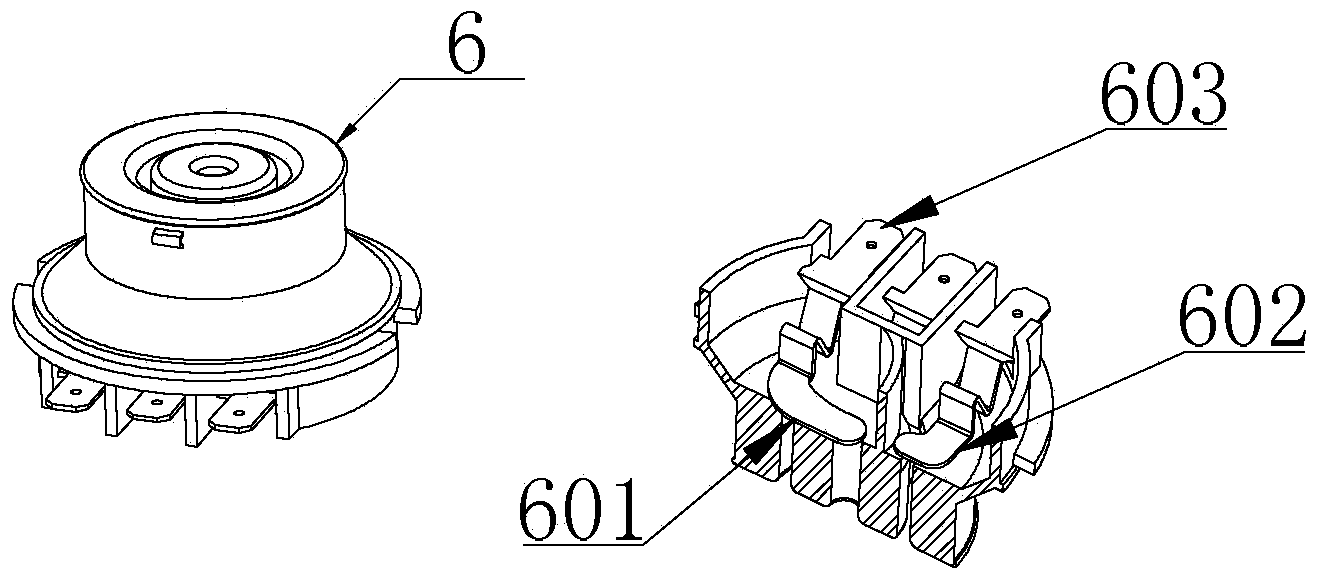

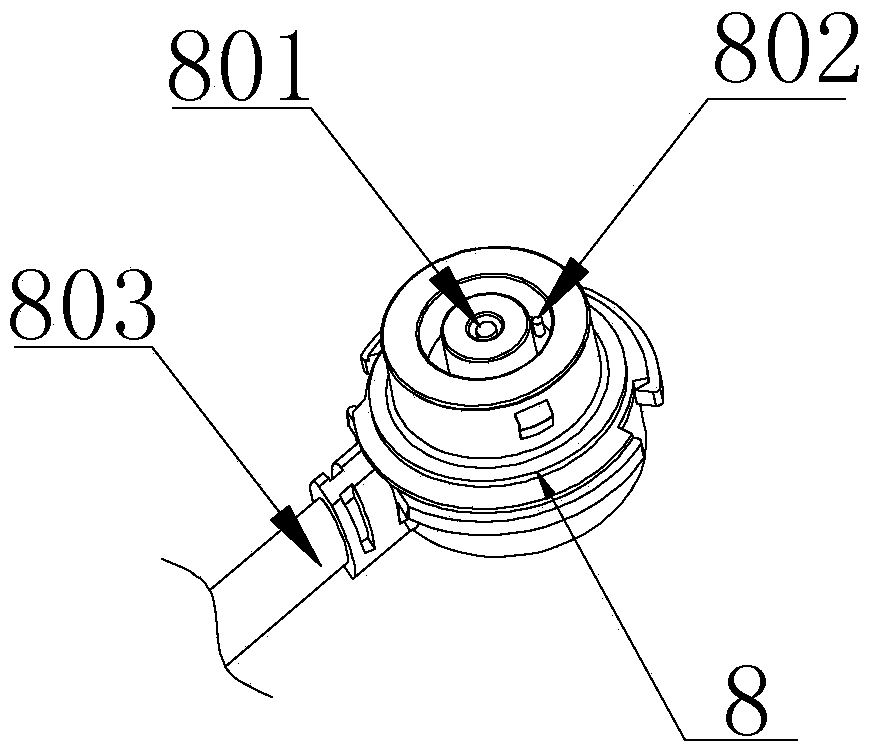

[0051] 1. Different compensation methods: figure 1 A common lower coupler 6 is shown in the common lower coupler 6. The positive copper sheet 601 and the negative copper sheet 602 that are in contact with the upper coupler are provided in the common lower coupler. The copper sheet itself has elasticity to realize the compensation with the upper coupler. The running size of the lower compensation is greater than 1.5 mm to ensure that the upper and lower couplers can still ensure contact when there are manufacturing errors in the kettle body, bottom cover assembly, pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com