A high-infrared curing device and method for brake pad steel back

A technology of infrared curing and brake pads, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of high energy consumption, difficult control of precision, low curing process efficiency of the brake pad steel back curing device, etc. Problems, achieve reasonable curing time, adjust curing time, improve curing quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

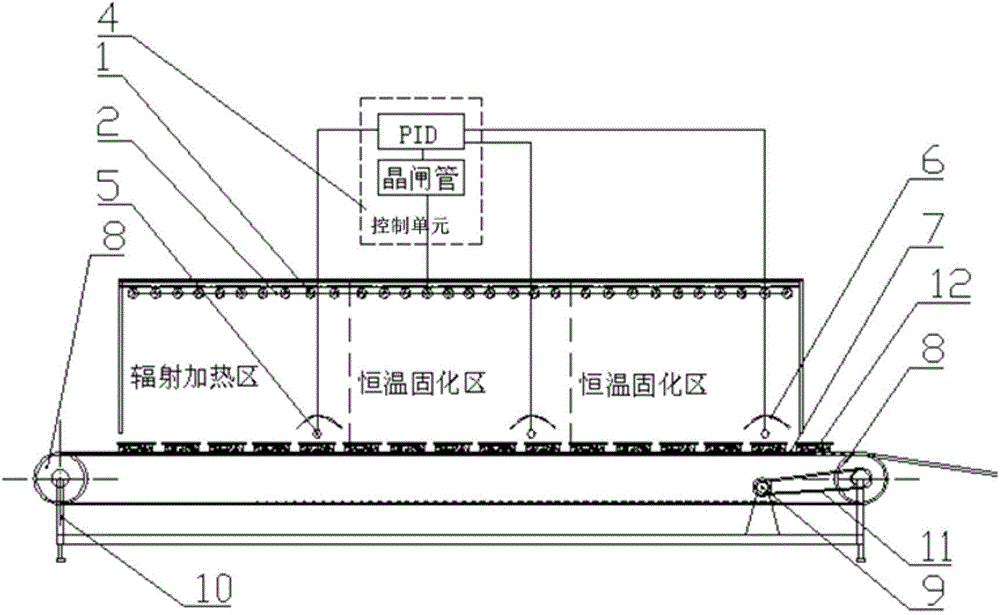

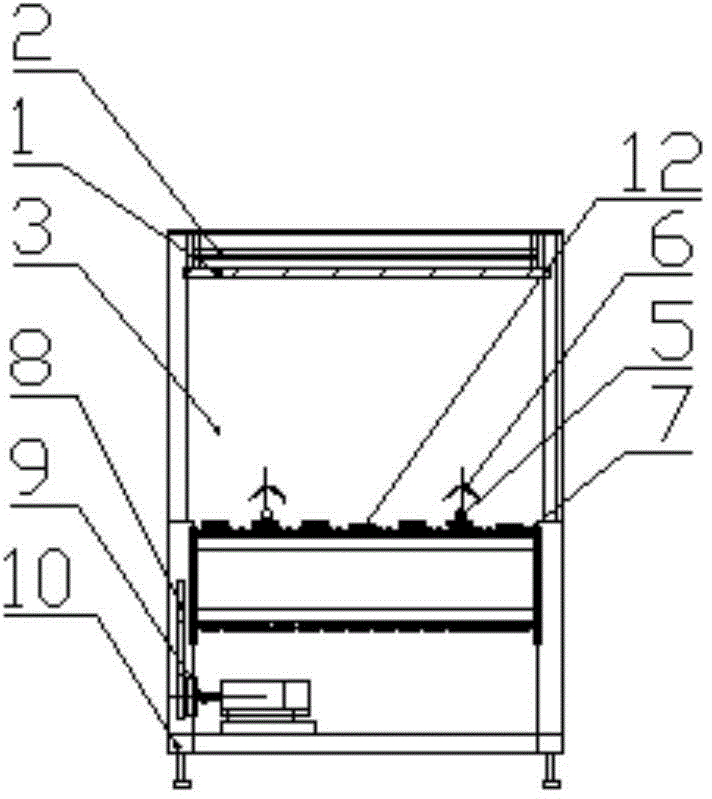

[0029] The high infrared curing method of the present embodiment may further comprise the steps:

[0030] Step 1: Turn on the high-infrared radiator 1 and the temperature control system of the high-infrared curing device, respectively set the constant temperature to be reached in the radiation heating zone in the curing chamber 3 to 170°C, and the two constant-temperature curing zones require The achieved constant temperature is 200°C, and the control accuracy of the temperature sensor is ±1°C;

[0031] Second step: start the speed-regulating motor 9 of the metal chain belt conveyor, and the running speed of the metal mesh conveyor belt 7 is controlled at 5 meters per minute;

[0032] The third step: when the temperature of the radiation heating zone and the constant temperature curing zone reach the constant temperature, the brake pad is placed on the running metal mesh conveyor belt 7, and the friction material part of the brake pad faces placed downwards, the part of the s...

Embodiment 2

[0034] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that: the set temperature of the radiation heating zone in the curing chamber 3 is 190°C, the set temperature of the two constant temperature curing zones is 220°C, and the control accuracy is ±1°C; The running speed of the metal mesh conveyor belt 7 is 6 m / min.

Embodiment 3

[0036] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that: the set temperature of the radiation heating zone in the curing chamber 3 is 180°C, the set temperature of the two constant temperature curing zones is 210°C, and the control accuracy is ±1°C; The running speed of the metal mesh conveyor belt 7 is 5.5 m / min.

[0037]A high-infrared curing device and method for the steel back of the brake pad according to the present invention, the curing device has a simple structure, a high degree of temperature control automation, fast curing speed, and low energy consumption; Spray curing, high production efficiency, high product quality, and effectively reduce production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com