A method for producing pipeline steel plates using continuous casting slabs under the condition of small compression ratio

A technology of compression ratio and continuous casting slabs, which is applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of not involving extra-thick and wide X65 pipeline steel plates, increasing smelting costs, etc., and achieves a large width-to-expansion ratio , Reduce smelting cost and facilitate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

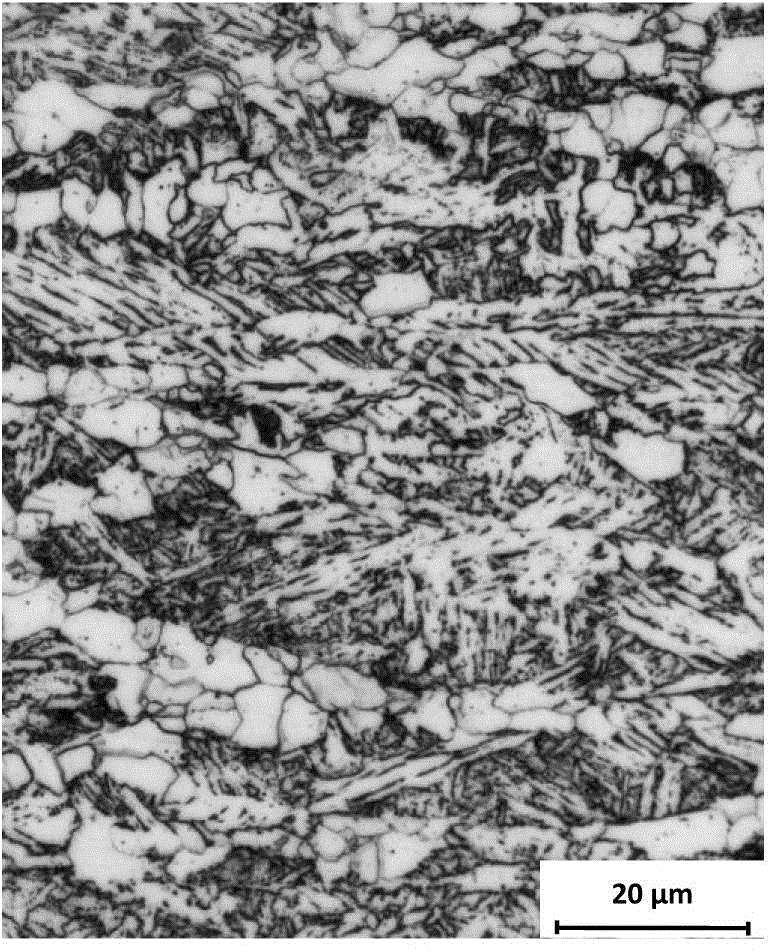

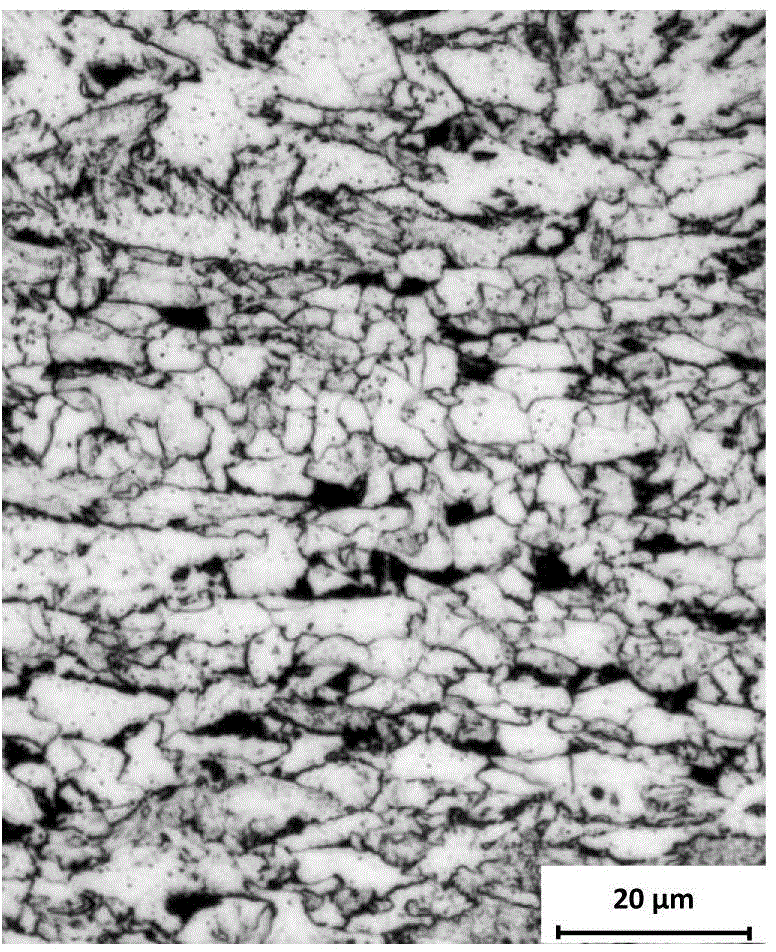

Embodiment 1

[0033]The chemical composition is (calculated by wt%): C: 0.09%, Si: 0.25%, Mn: 1.5%, S: 0.002%, P: 0.012%, Nb: 0.05%, V: 0.04%, Ti: 0.02% , the rest is Fe and unavoidable impurities, and the continuous casting slab with a cross-sectional size of 300mm in thickness and 2000mm in width is sent into a walking heating furnace to be heated to 1215°C and kept for 500 minutes. The heated continuous casting slab is rolled in the austenite recrystallization zone and austenite non-recrystallization zone rolling. In the rolling of the austenite recrystallization zone, the starting rolling temperature is 1190 ° C, and the finishing rolling temperature is 1140 ° C. ℃, in the rolling in the austenite recrystallization zone, the width of the continuous casting slab is first rolled continuously from 2000mm to 3600mm, and the thickness is 175mm so that the longitudinal cumulative compression ratio is 3.5 (175mm / 50mm). Continuous longitudinal rolling of the continuous casting slab until the th...

Embodiment 2

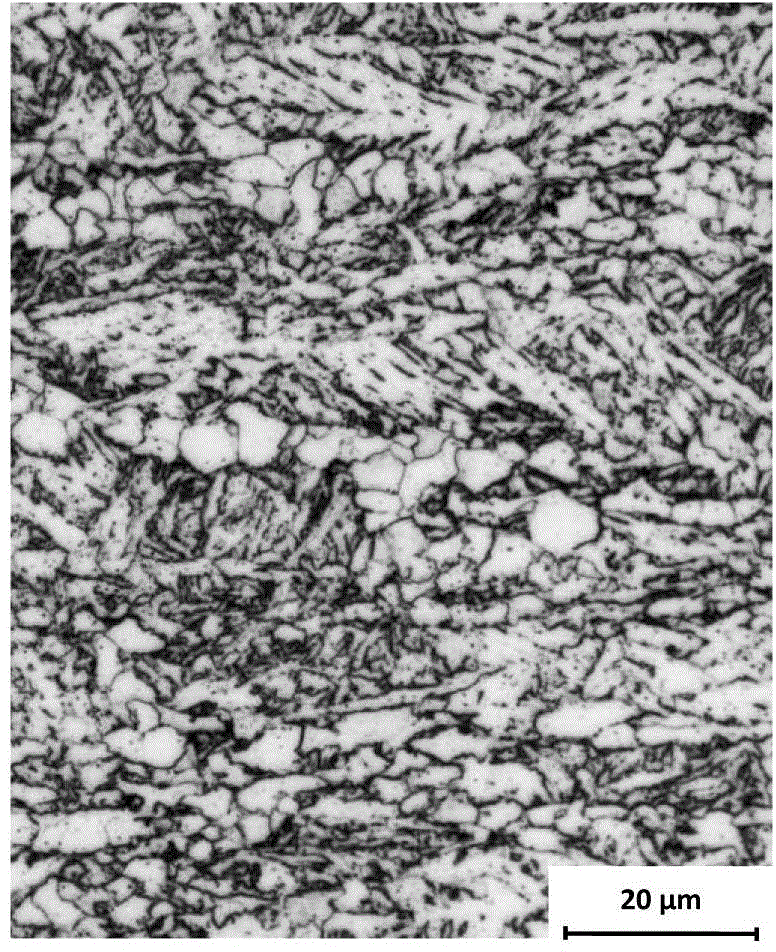

[0035] The chemical composition is (calculated by wt%): C: 0.09%, Si: 0.25%, Mn: 1.5%, S: 0.002%, P: 0.012%, Nb: 0.05%, V: 0.04%, Ti: 0.02% , the rest is Fe and unavoidable impurities, and the continuous casting slab with a cross-sectional size of 300mm in thickness and 2000mm in width is sent into a walking heating furnace and heated to 1215°C and kept for 500 minutes. The heated continuous casting slab is rolled in the austenite recrystallization zone and austenite non-recrystallization zone rolling. In the rolling of the austenite recrystallization zone, the starting rolling temperature is 1190 ° C, and the finishing rolling temperature is 1140 ° C. ℃, in the rolling in the austenite recrystallization zone, the width of the continuous cast slab is first continuously extended and rolled from 2000mm to 3700mm, and the thickness is 144mm so that the longitudinal cumulative compression ratio is 3.6 (144mm / 40mm). Continuous longitudinal rolling of the continuous casting slab unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Charpy impact | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com