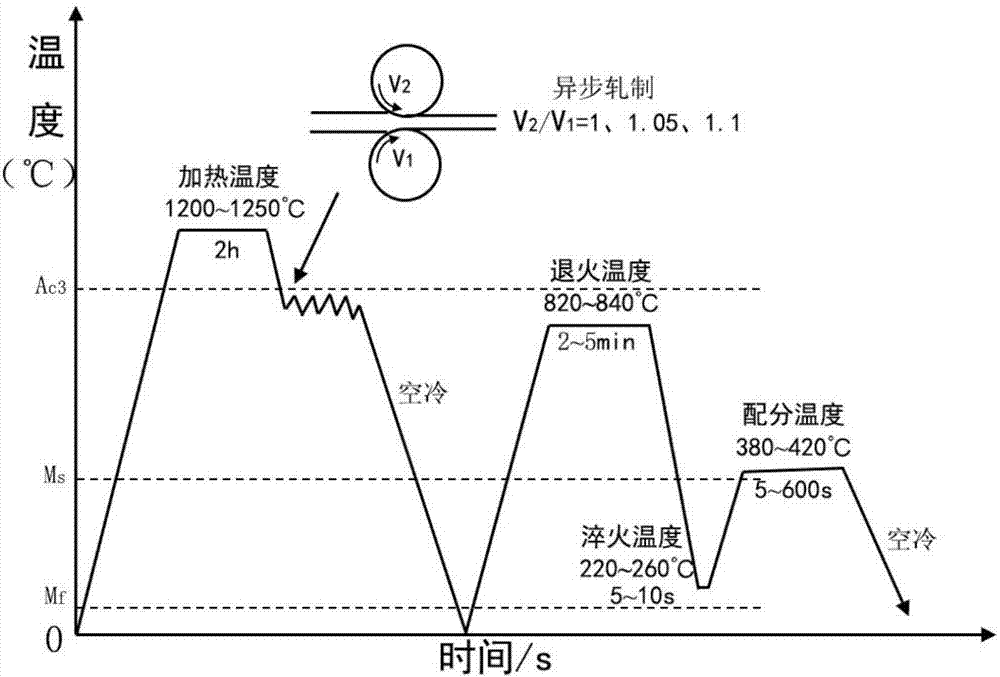

High-strength plastic-laden low-carbon silicon-manganese q&p steel plate and its preparation method by asynchronous rolling

A high-strength plastic product, asynchronous rolling technology, applied in the field of material processing, to achieve good plasticity, reduce rolling force, and refine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]A high-strength ductile low-carbon silicon-manganese Q&P steel plate, the mass percentage of its chemical components is: C: 0.18%, Mn: 1.44%, Si: 1.48%, Al: 0.15%, Nb: 0.025%, and The amount is Fe and other unavoidable impurities.

[0042] The preparation method of the asynchronous rolling of the above-mentioned high-strength plasticity low-carbon silicon-manganese series Q&P steel plate comprises the following steps:

[0043] Step 1, prepare the slab:

[0044] After smelting and casting according to the chemical composition of high-strength plasticity low-carbon silicon-manganese series Q&P steel, a slab with a thickness of 30mm is obtained, wherein the forging heating temperature is 1250°C, the holding time is 3h, and the forging deformation temperature is 900-1050°C;

[0045] Step 2, asynchronous rolling:

[0046] (1) Heat the Q&P steel slab to 1200°C for 2 hours;

[0047] (2) After asynchronously rolling the Q&P steel slabs after heat preservation, air-cool to roo...

Embodiment 2

[0053] A high-strength plastic-laden low-carbon silicon-manganese Q&P steel plate, the mass percentage of its chemical components is: C: 0.21%, Mn: 1.52%, Si: 1.55%, Al: 0.13%, Nb: 0.05%, and The amount is Fe and other unavoidable impurities.

[0054] The preparation method of the asynchronous rolling of the above-mentioned high-strength plasticity low-carbon silicon-manganese series Q&P steel plate comprises the following steps:

[0055] Step 1, prepare the slab:

[0056] After smelting and casting according to the chemical composition of high-strength plasticity low-carbon silicon-manganese Q&P steel, a slab with a thickness of 30mm is obtained. The forging heating temperature is 1220°C, the holding time is 2.5h, and the forging deformation temperature is 900-1050°C. ;

[0057] Step 2, asynchronous rolling:

[0058] (1) Heat the Q&P steel slab to 1250°C for 2 hours;

[0059] (2) After asynchronously rolling the Q&P steel slabs after heat preservation, air-cool to room te...

Embodiment 3

[0065] A high-strength plastic-laden low-carbon silicon-manganese Q&P steel plate, the mass percentage of its chemical components is: C: 0.23%, Mn: 1.58%, Si: 1.60%, Al: 0.17%, Nb: 0.06%, and The amount is Fe and other unavoidable impurities.

[0066] The preparation method of the asynchronous rolling of the above-mentioned high-strength plasticity low-carbon silicon-manganese series Q&P steel plate comprises the following steps:

[0067] Step 1, prepare the slab:

[0068] After smelting and casting according to the chemical composition of high-strength plasticity low-carbon silicon-manganese Q&P steel, a slab with a thickness of 30mm was obtained. The forging heating temperature was 1200°C, the holding time was 2h, and the forging deformation temperature was 900-1050°C.

[0069] Step 2, asynchronous rolling:

[0070] (1) Heat the Q&P steel slab to 1230°C for 2 hours;

[0071] (2) After asynchronously rolling the Q&P steel slabs after heat preservation, air-cool to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com