Rolling oil amount control method for cold-rolling mill

A control method and rolling oil technology, which are applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of fixing, increase processing cost, increase filter tank work, etc., so as to reduce production cost and reduce fuel injection. The effect of oil consumption and oil saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Specific embodiments of the present invention are described in detail below.

[0008] According to the method for controlling the amount of rolling oil in a cold rolling mill according to the present invention, the valves at each oil injection place during the rolling process control the amount of oil according to the following formula, L=7100-A×S+B×R×1000, where 0.190 ≤A≤0.195, 1.50≤B≤1.55, L is the flow rate, its unit is L / min, S is the real-time rolling speed, its unit is m / min, R is the real-time reduction rate. In order to save oil to the greatest extent, in actual production, A takes 0.193, and B takes 1.53.

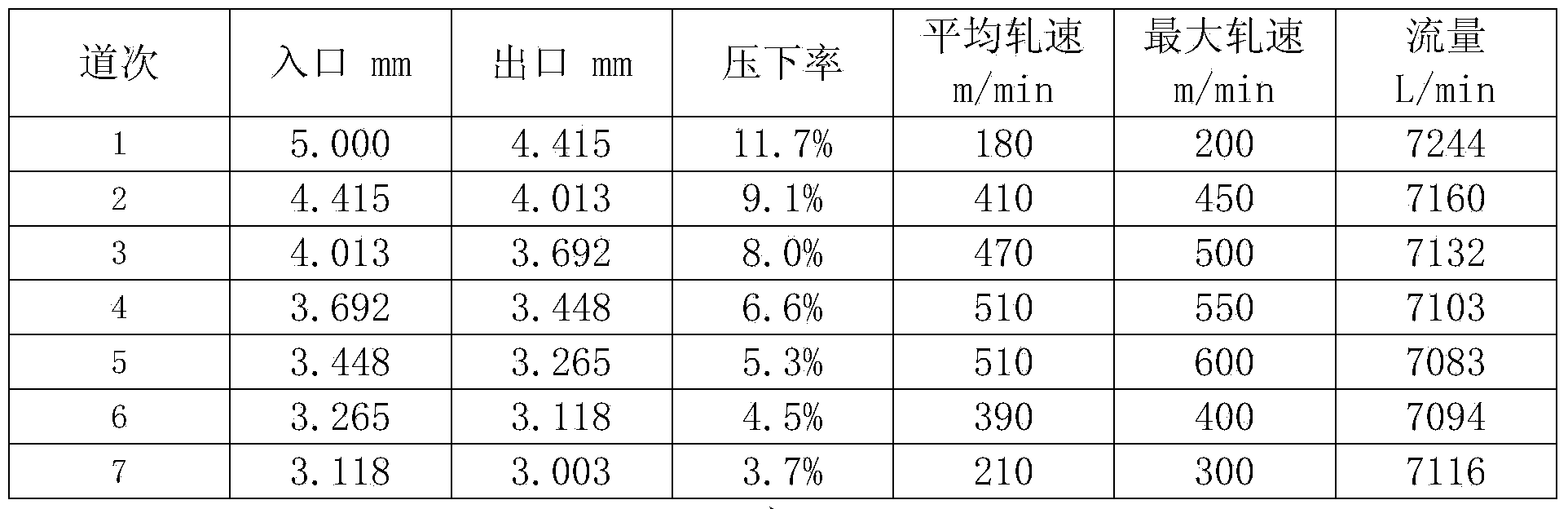

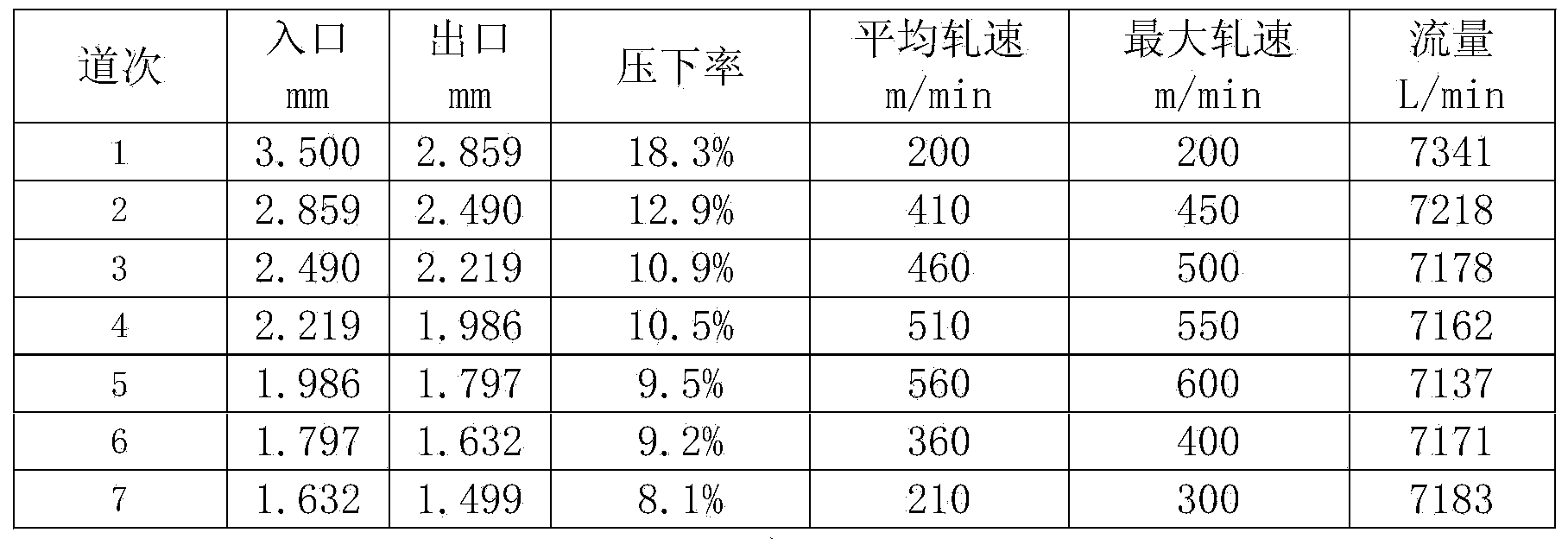

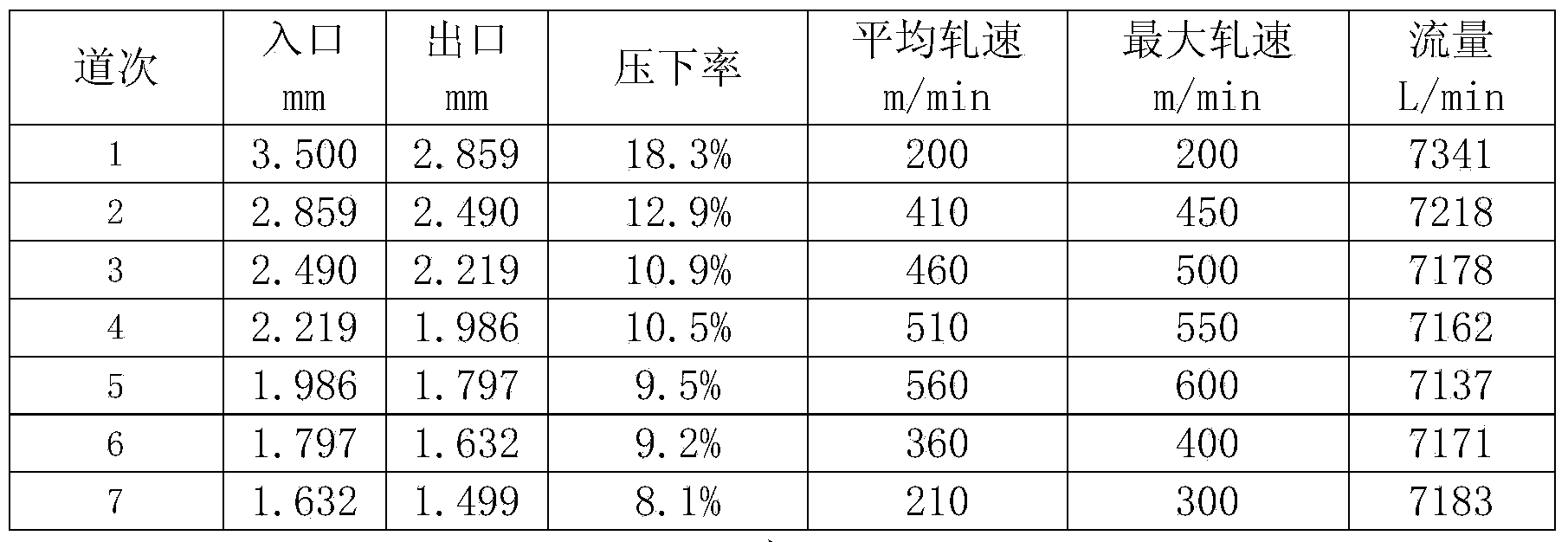

[0009] Mainly confirm the three rolling methods of rolling from 5.0mm to 3.0mm, rolling from 4.0mm to 2.0tmm, and rolling from 3.5mm to 1.5mm. The above-mentioned three methods set the pass arrangement to be 7 passes, and the reduction rate and average running speed of each pass are detailed as follows: (See Table 2, Table 3 and Table 4) Since S is constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com