Derusting equipment and derusting method for inner liner polishing

A technology of finishing and equipment, which is applied in the field of finishing and derusting equipment for inner tanks and its derusting field, and can solve problems such as difficulty in derusting the inner surface of bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

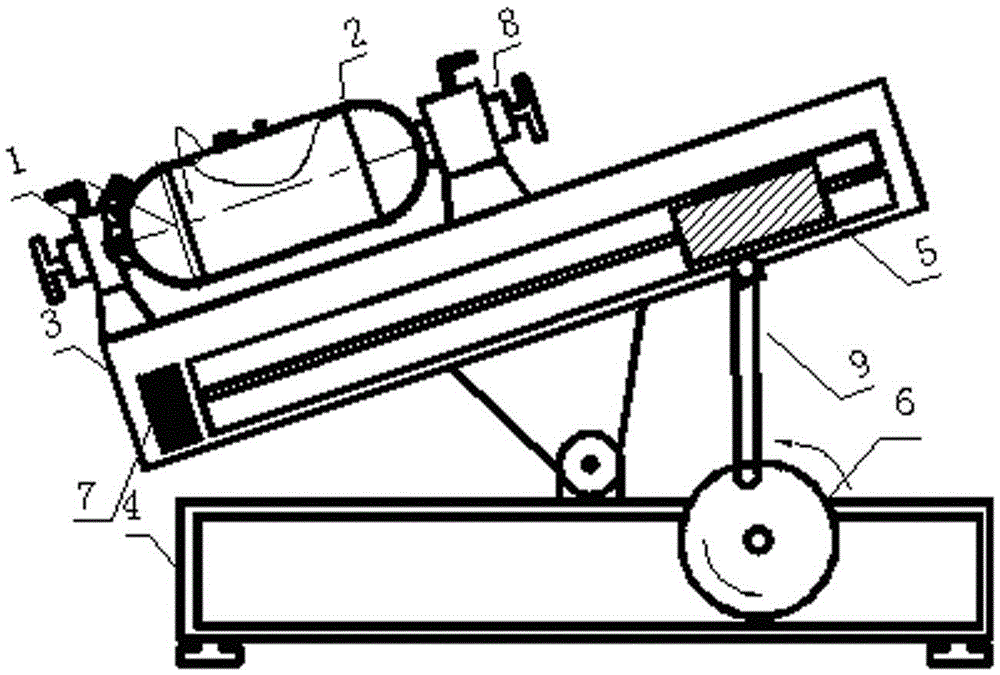

[0026] Motor I6 is installed on the base 4, and motor I is connected to platform 3 through eccentric wheel rocker arm 9, and platform 3 is provided with motor II7 and counterweight 5, and motor II is connected to bottle body 2 through chain, and the top of platform 3 is provided with for fixing A fixed frame of the bottle body 2; the fixed frame is composed of a chuck 1 and a tail top 8.

[0027] Taking the small-bore cylinder as an example, the derusting method of the present invention comprises the following steps:

[0028] Fill the bottle to be processed with high-hardness abrasives and grinding liquid, and fix the bottle body with the tail top and the chuck; when the motor II is working, the bottle body is driven to rotate by the chain; the abrasive in the bottle body rotates under gravity and the bottle body The relative movement is generated under the action of the motor, so as to achieve the effect of cutting the surface; when the motor I rotates, the eccentric rocker a...

Embodiment 2

[0034] The concentration of described sodium nitrite solution is 15g / L, and the concentration of sodium carbonate solution is 2g / L, and other structures and methods are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com