Die cleaning line, die cleaning equipment and die cleaning method for tubular piles

A mold cleaning and equipment technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of unsuitable concrete pipe pile mold cleaning, mold cleaning process needs to be further improved, and is not conducive to reducing production costs, so as to avoid the influence of subjective factors , improve safety, and ensure the effect of mold cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific embodiment:

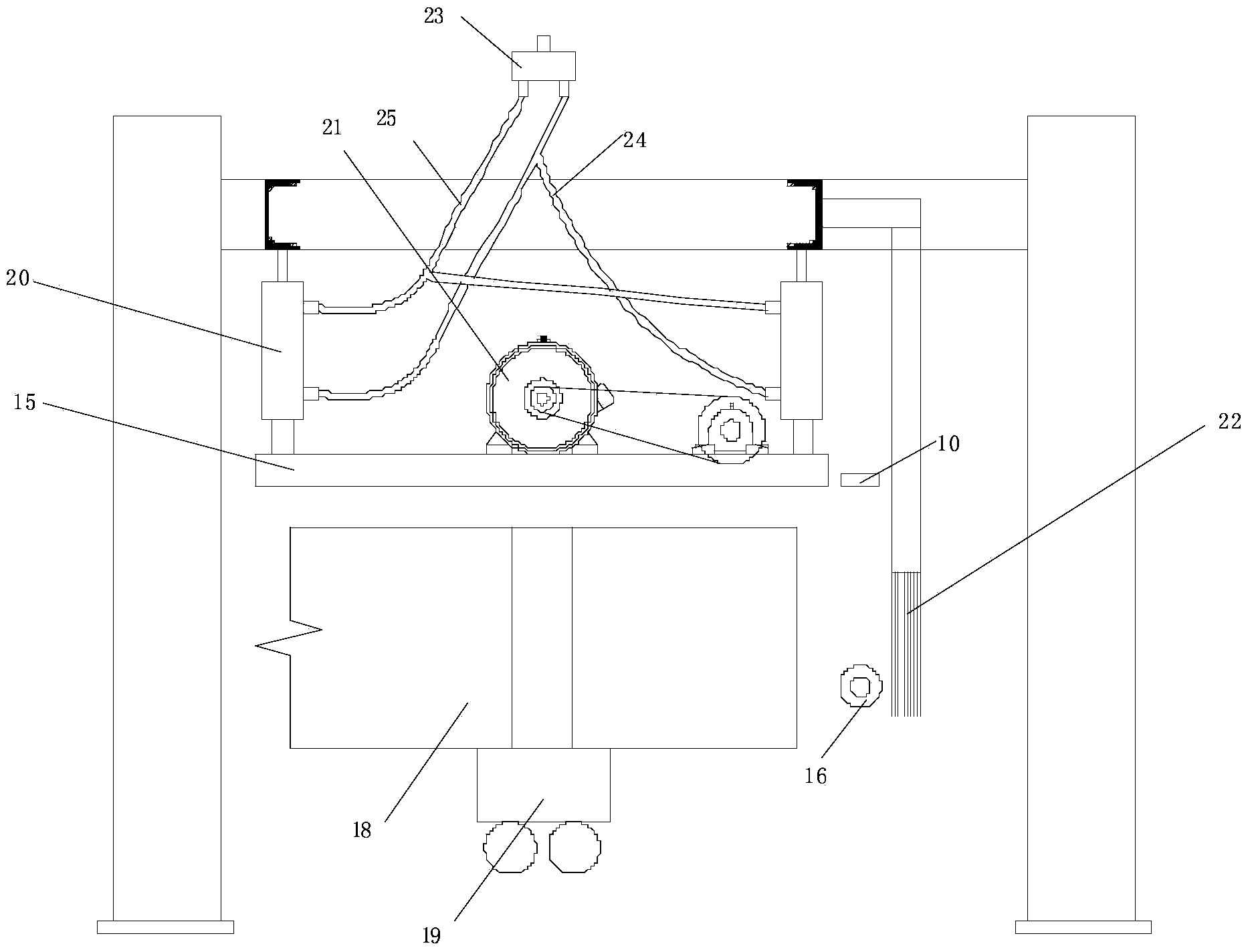

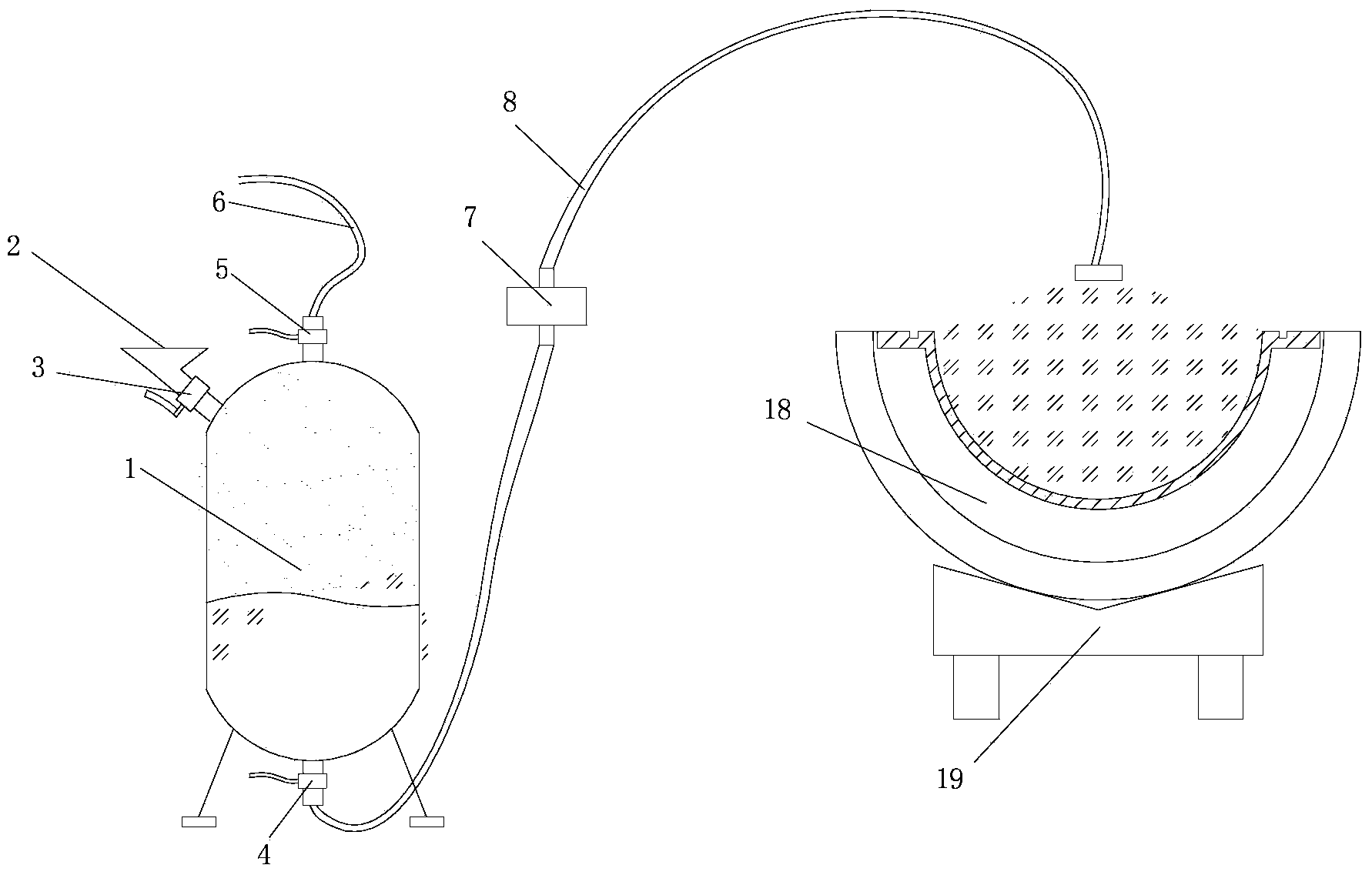

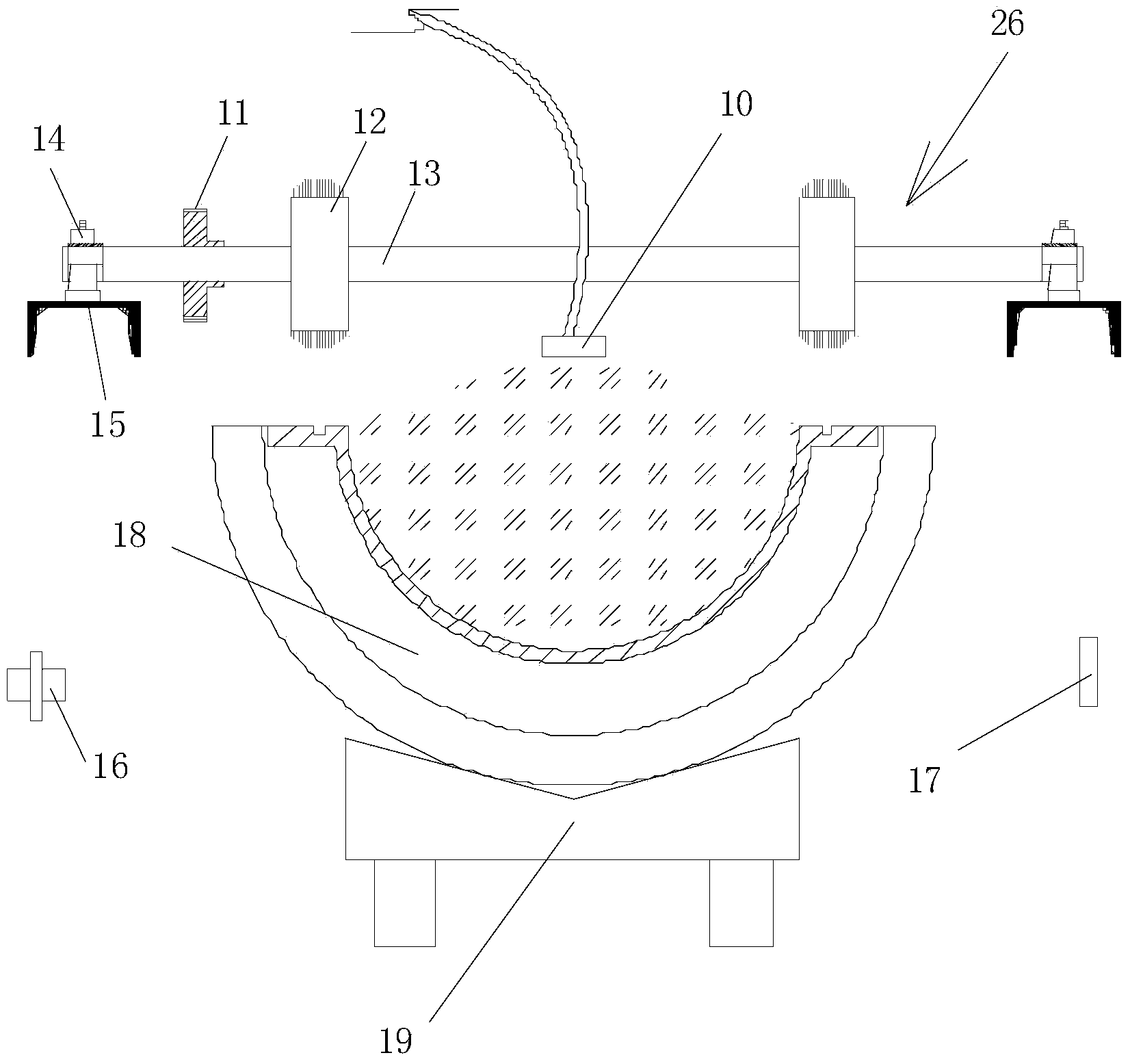

[0044] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a pipe pile mold cleaning circuit includes mold release agent spraying equipment, mold cleaning equipment, pipe mold conveying equipment and a photoelectric switch, the discharge nozzle 10 of the photoelectric switch, mold release agent spraying equipment and mold cleaning equipment along the pipe mold The conveying equipment 19 is set in sequence before and after the moving direction; the release agent spraying equipment is provided with a first electronically controlled valve 7 that controls the release nozzle 10 on and off;

[0045] The mold cleaning equipment includes a bracket 9, a lifting device 20, a notch cleaner 26 and an inner chamber cleaner 22, the notch cleaner 26 and the inner chamber cleaner 22 are set up and down, and the inner chamber cleaner 22 is located directly above the pipe mold,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com