Polarizer repair device

A polarizer and repair technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of affecting the quality of the LCD screen, inconvenient flipping the LCD screen, and sinking the LCD screen downwards, etc., to achieve simple structure, easy flipping and labor saving, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

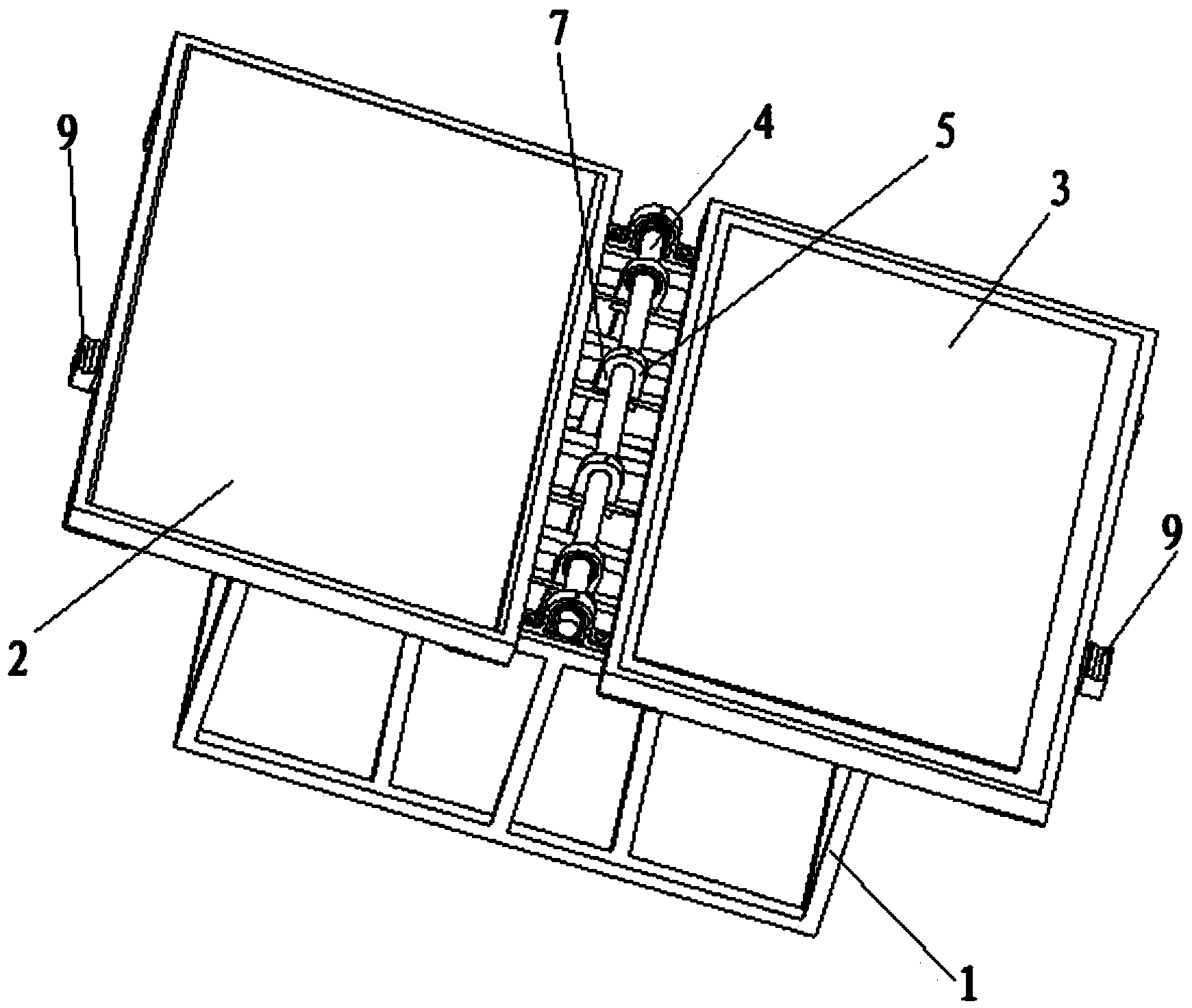

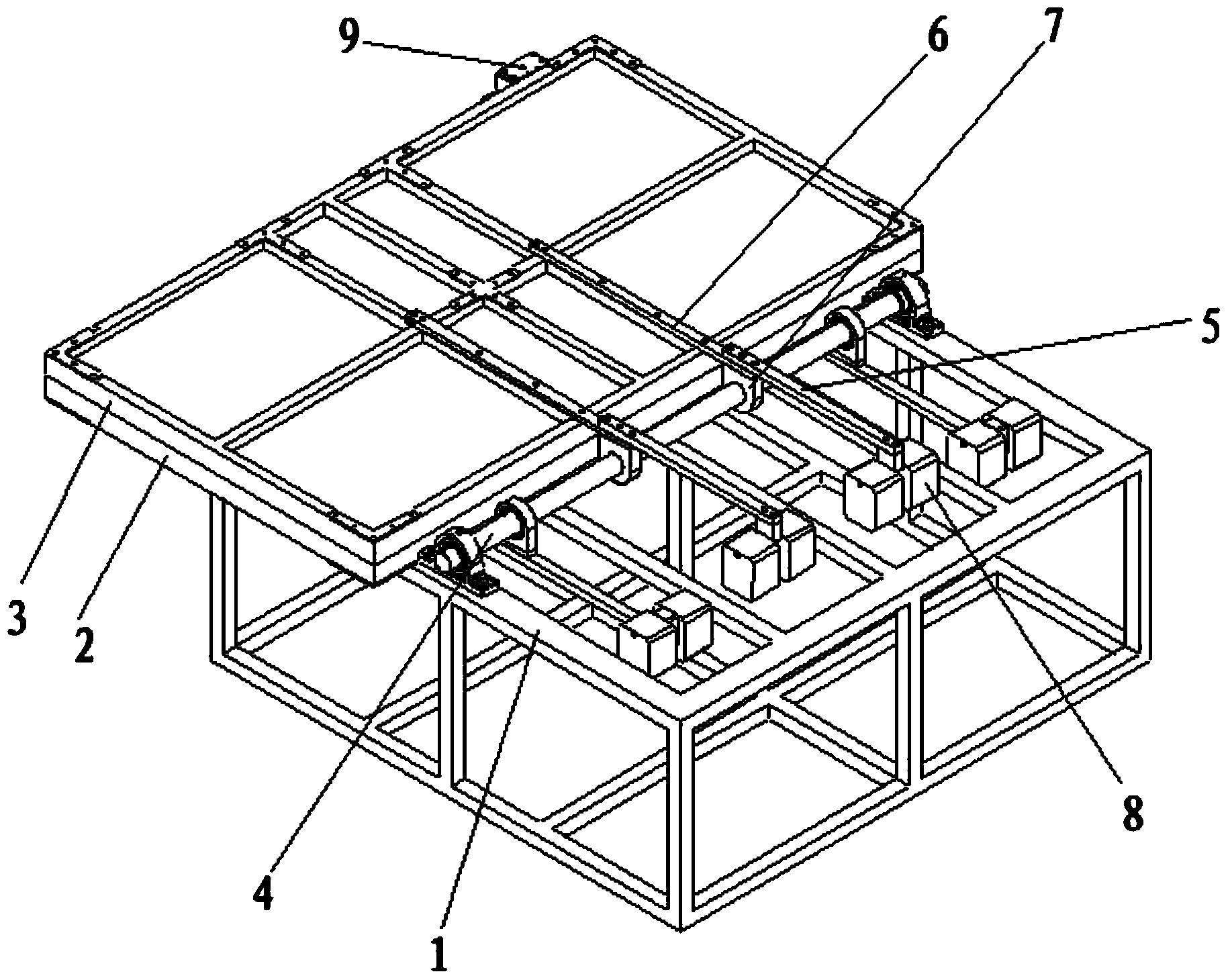

[0019] like Figure 1-2 As shown, a polarizer rework equipment, including: a base 1, a left plate 2 and a right plate 3 located on the base 1, characterized in that: a fixed shaft 4 is arranged in the middle of the left plate 2 and the right plate 3, The fixed shaft 4 is fixedly connected to the base 1, the left plate 2 and the right plate 3 are rotatably connected to the fixed shaft 4 through at least two rotating mechanisms 5, and the right plate 3 or the left plate 2 A first groove for placing materials is arranged in the upper surface.

[0020] The rotating mechanism 5 includes a movable rod 6 and a protruding plate 7 located in the middle of the movable rod 6, the movable rod 6 and the protruding plate 7 are integrally formed, and the protruding plate 7 is provided with a The through hole of the fixed shaft 4, one end of the rotating mechanism 5 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com