Shear mode coal grab bucket structure

A technology of grab bucket and hinge structure, applied in the directions of load hanging components, transportation and packaging, can solve the problems of low work efficiency and poor reliability of use, and achieve the effect of high work efficiency, convenient installation and use, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

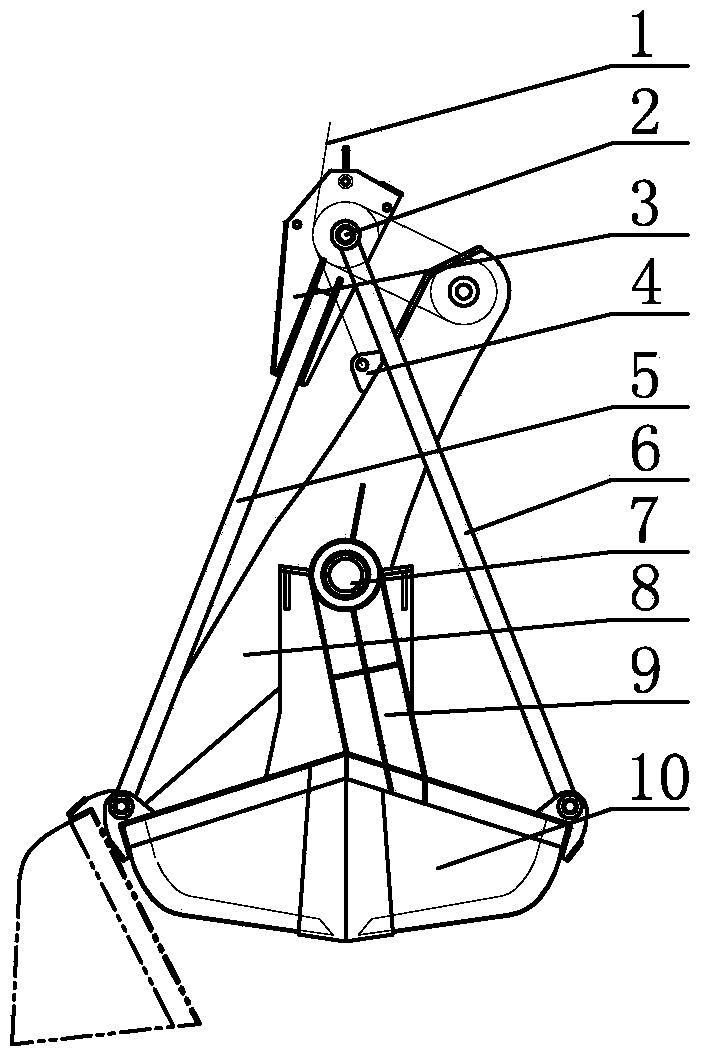

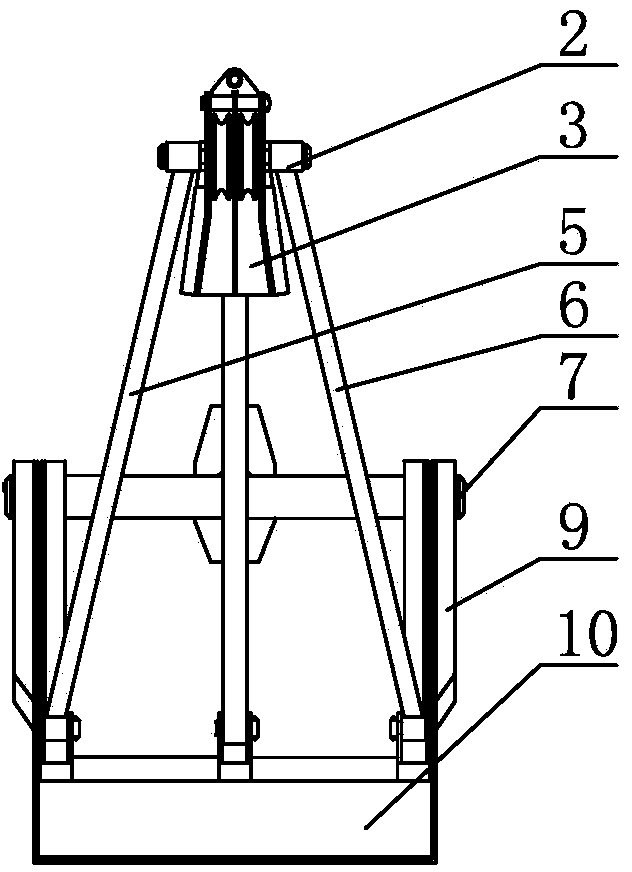

[0012] Such as figure 1 and figure 2 As shown, the scissor coal grab structure of this embodiment includes a grab head 3, and the two ends of the grab head 3 are respectively connected with a first support rod 5 and a second support rod 6 through a first hinge structure 2, The bottom of the first support bar 5 and the second support bar 6 hinge the bucket body 10; also include a crossbeam 8, the head of the crossbeam 8 is provided with a second pulley block, and the middle part of the crossbeam 8 is installed with a connecting rod 9 through a second hinge structure 7, and the connecting rod One end of 9 is fixed on the bucket body 10; one side of the beam 8 is also provided with a fixture 4, the first pulley block is installed on the grab head 3, and the wire rope 1 bypasses the first pulley block, the second pulley block and the fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com