Bleeding-resistant waterborne wood sealing primer

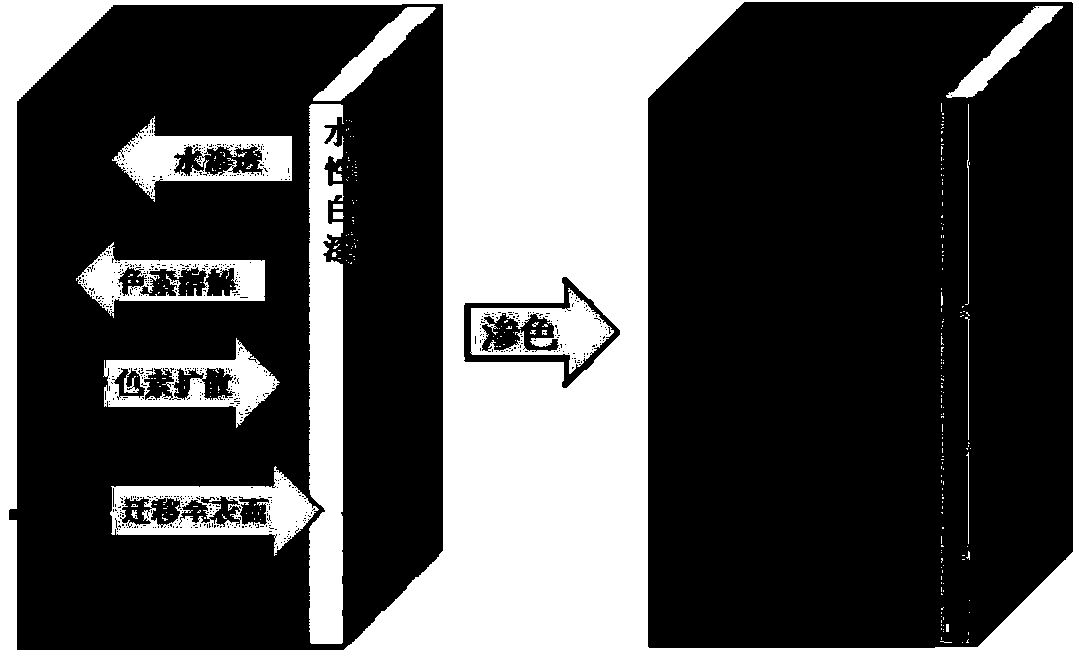

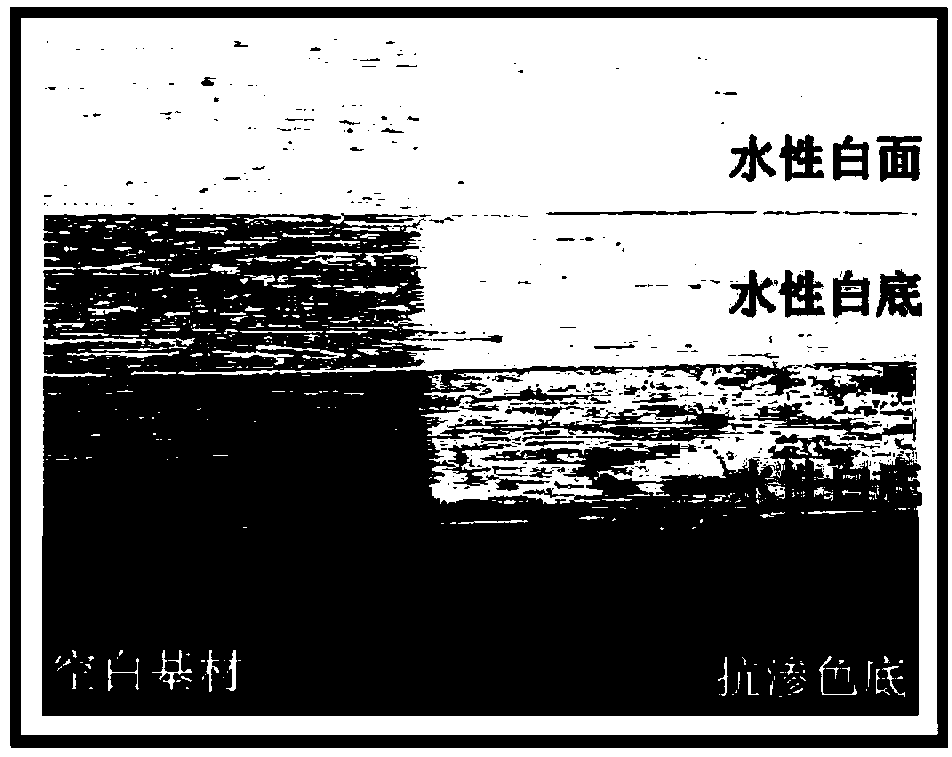

A sealing primer and anti-bleeding technology, applied in the field of primers, can solve the application range of anti-bleeding additives, the comprehensive effect is not ideal, the anti-bleeding additives and the anti-bleeding emulsion are not well combined, and the system is affected. Storage stability and other issues, to achieve good anti-bleeding effect, good physical barrier effect, good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

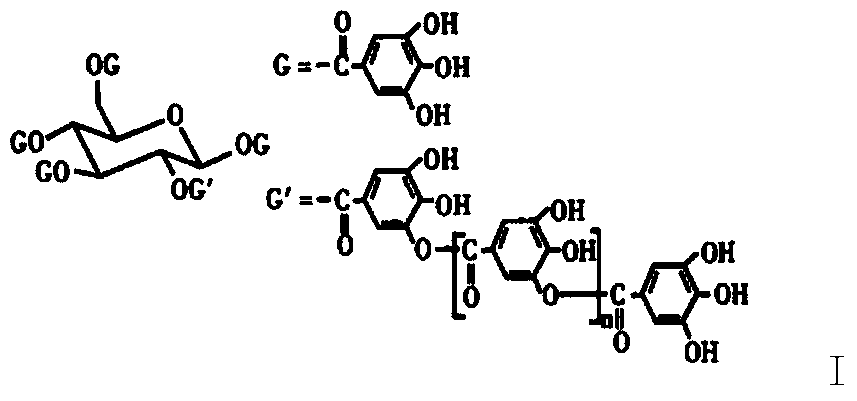

Method used

Image

Examples

Embodiment 1-8

[0047] Examples 1-8 used cationic acrylic emulsion AC-146 from Picassian polymers company, and the formula is shown in Table 1. Wherein embodiment 1,5,7 is the prescription without adding auxiliary agent, and it is as the comparative example of the present invention.

[0048] Table 1

[0049]

[0050]

Embodiment 9

[0052] Embodiment 9-embodiment 13 adopts the cation-modified acrylic acid copolymer dispersion of Interpolymer company 6305, the formula is shown in Table 2. Wherein embodiment 9 is the prescription that does not add auxiliary agent, and it is as the comparative example of the present invention.

[0053] Table 2

[0054]

[0055]

Embodiment 14

[0057] Example 14-Example 16 used Cytec's epoxy ester resin DUROXYN VEF2406w / 45WA, and the formula is shown in Table 3. Wherein embodiment 14 is the prescription that does not add auxiliary agent, and it is as the comparative example of the present invention.

[0058] table 3

[0059]

[0060]

[0061] The preparation methods of the above-mentioned examples are as follows: (1) Add material 1 into the container under the shutdown state; under medium-speed stirring state, mix 2 and 3 according to the formula amount, and then slowly add;

[0062] (2) According to the ratio, wash the film-forming aid stirring container with 4, add it slowly, and stir at a medium speed for 5 minutes until the mixture is uniform;

[0063] (3) Add 5 and 6 in sequence under medium-speed stirring, and disperse at high speed for 15 minutes until there is no oil vortex;

[0064] (4) Add 7, 8, 9, and 10 under medium-speed stirring, and continue to disperse for 10 minutes to make the system uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com