Air compressor

A technology of air compressor and tabletting, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of complex piston structure, high working noise and low working efficiency, so as to improve working efficiency and save replacement cost , the effect of sufficient air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

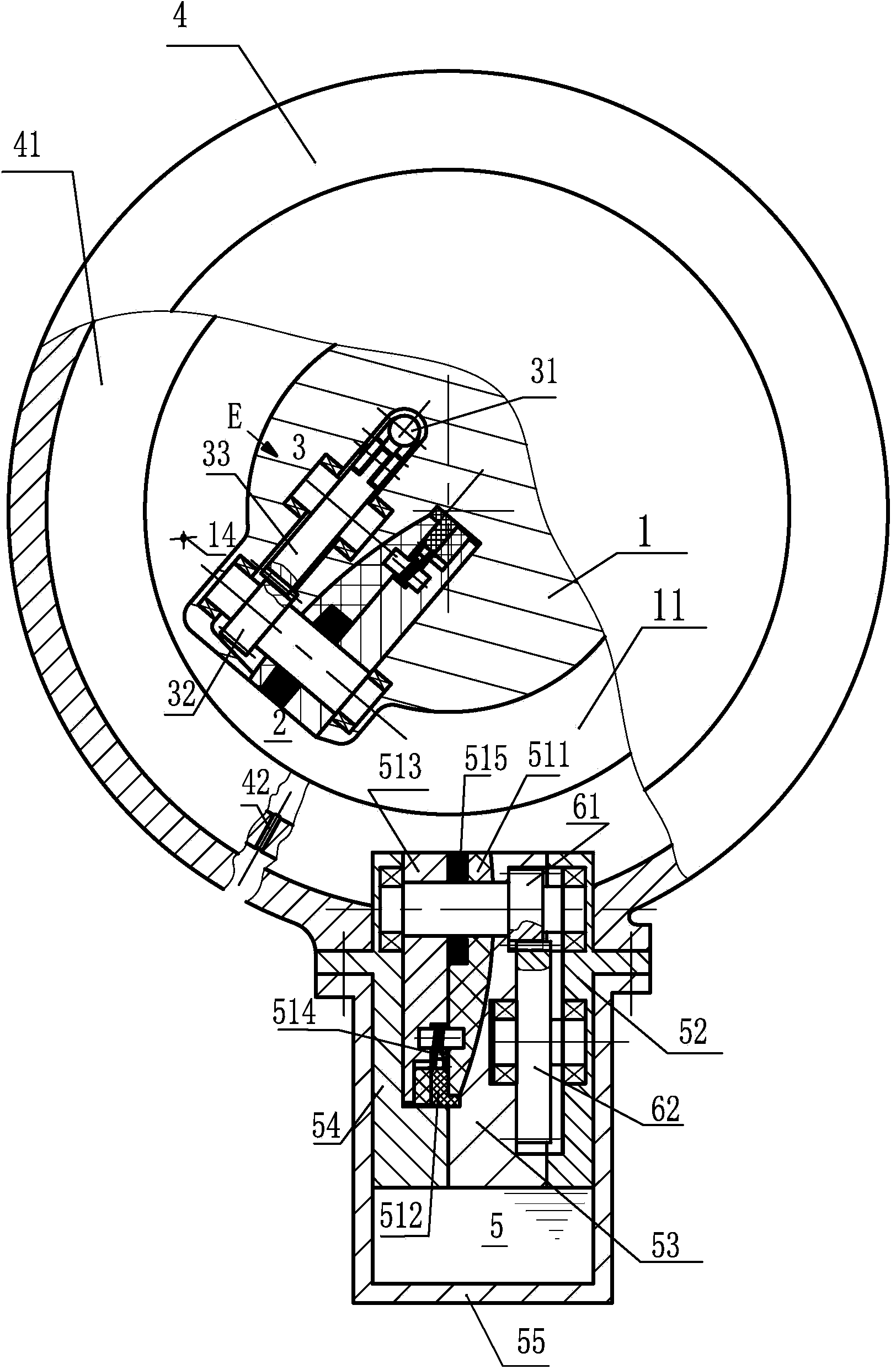

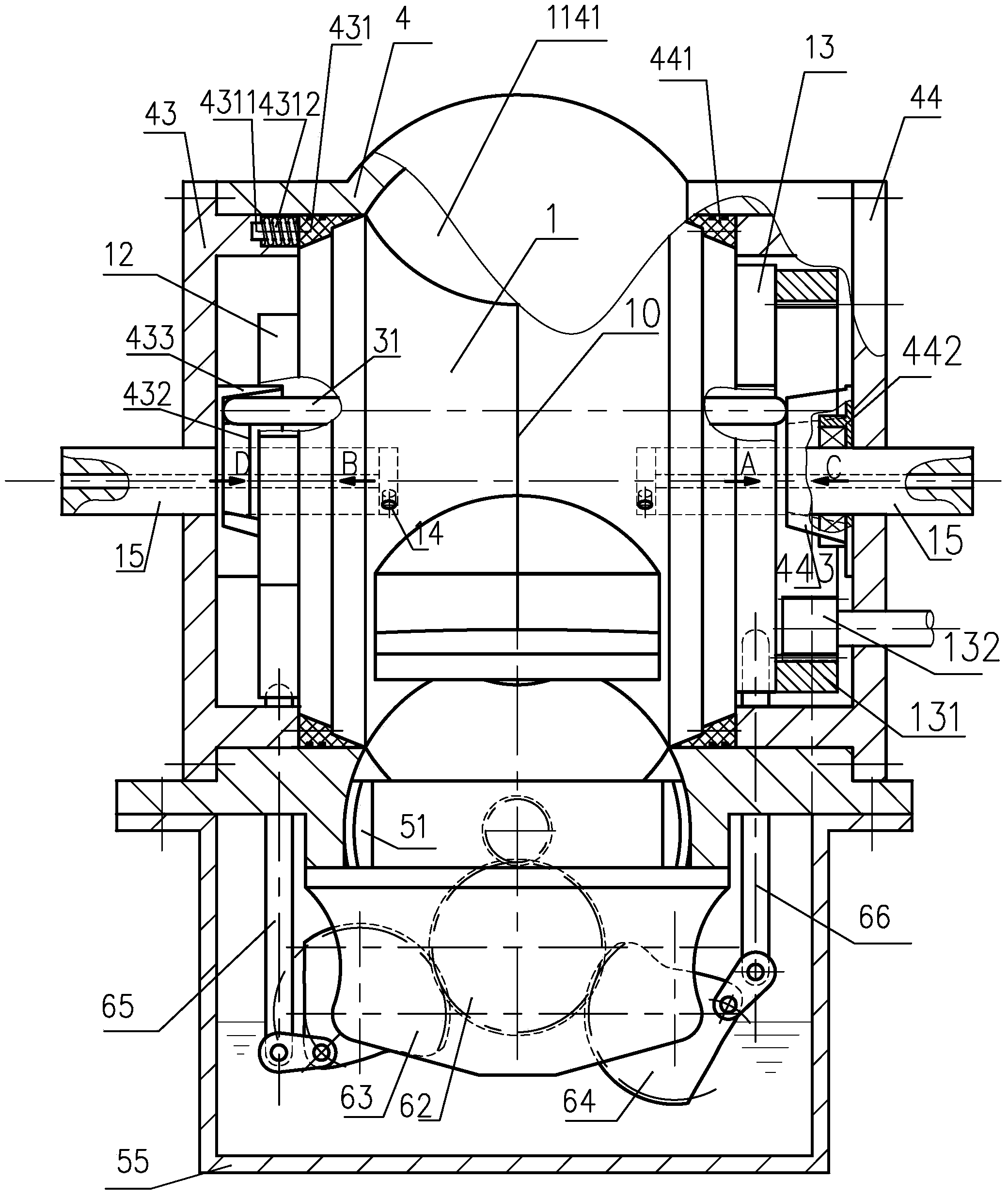

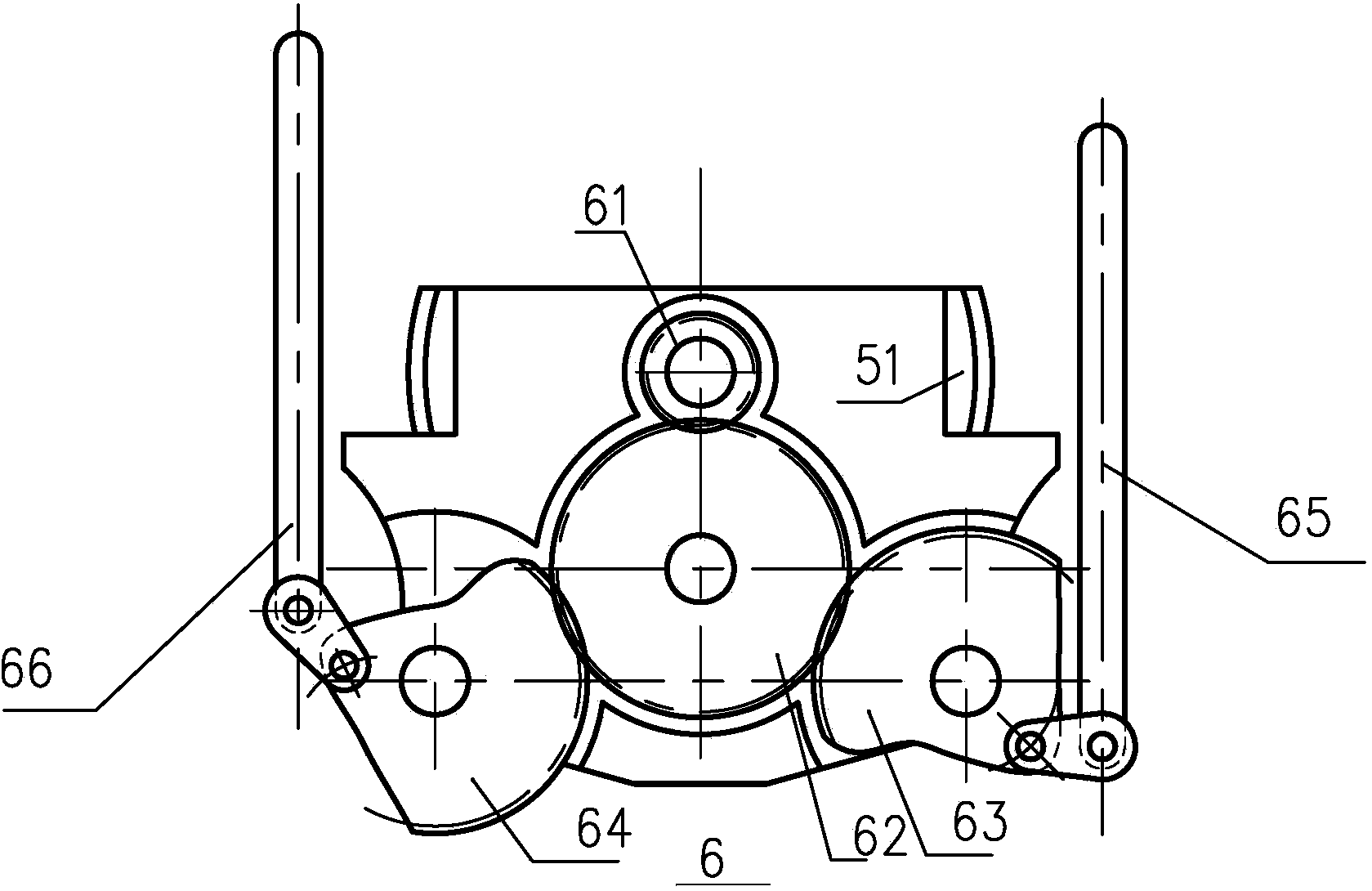

[0041] like figure 1 ,2 Shown is a schematic diagram of the overall structure of the air compressor of the present invention. The air compressor includes a rotor 1, a housing 4, an air inlet 14, and an air outlet 42. The rotor 1 has a rotor recess 11 surrounding the rotor 1, and the housing 4 has a housing recess 41 corresponding to the rotor recess 11. , the rotor recess 11 and the housing recess 41 cooperate with each other to form a working chamber 1141. A tongue is retractable and retractable in the working chamber 1141, and can be used to control the gas in the working chamber 1141 during the rotation of the rotor 1. compression. The tongue device further comprises: a first tongue device 5, which has a first tongue 51 that can be sealingly matched with the rotor recess 11 during the rotation of the rotor 1, the first tongue 51 is in the first tongue driving device 6 The second tongue device is arranged on the rotor 1 and has a second tongue 2 matched with the housing re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com