A led display wall mount bracket

A technology of LED display screen and support frame, which is applied in the direction of machines/brackets, support machines, mechanical equipment, etc. It can solve the problems of large-scale system maintenance difficulties, display screen plane deformation, difficulty in opening or closing, etc., and achieve good adaptability , Easy installation and maintenance, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

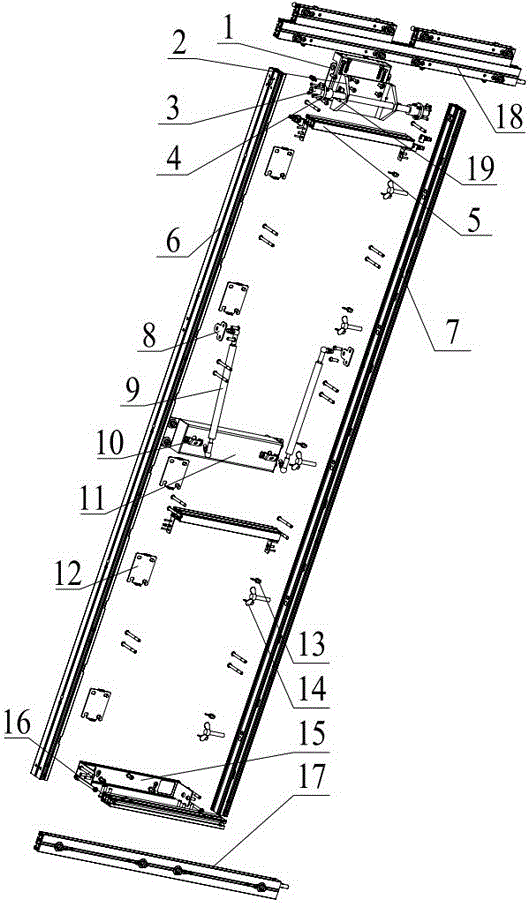

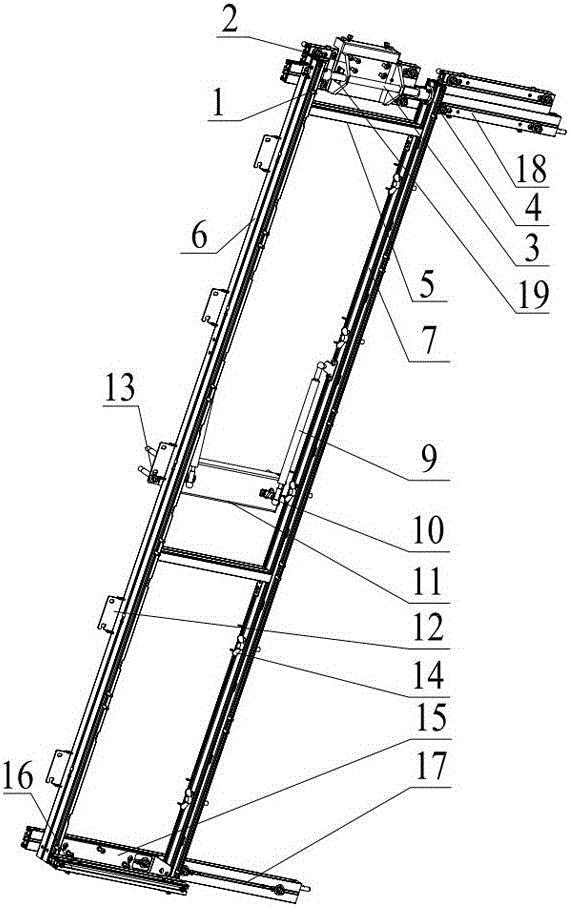

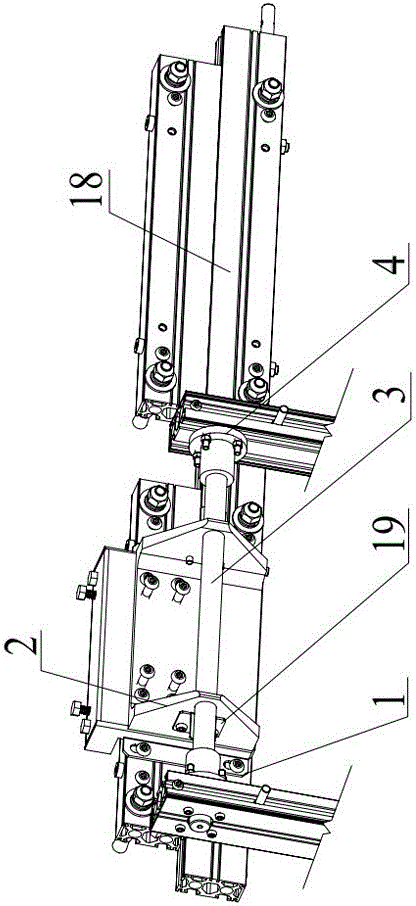

[0024] Such as figure 1 , 2 As shown, a LED display wall hanging bracket, which includes a wall hanging support 18 fixed on the wall, a support frame assembly for supporting the display screen, an upper end support shaft assembly, a gas spring assembly, a lower end adjustment assembly, and an adjustment between rows Components, lower end pedestal 17;

[0025] The upper end support shaft assembly is provided with a shaft seat 2 and a shaft 3 connected with the shaft seat 2, the shaft seat 2 is connected with the wall support 18, the support frame assembly is connected with the shaft 3 in rotation; one end of the gas spring assembly is connected with the wall, and the other end is connected with the support The frame components are connected; the lower end adjustment assembly is arranged at the bottom of the support frame assembly, the inter-row adjustment assembly is arranged at the display screen of the adjacent row, and the lower end pedestal 17 is fixed on the wall.

[002...

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is that when the number of rows and columns of the display screen is greater than or equal to three, the inter-column adjustment components are only distributed on the upper and lower ends of the left support column and the right support column, and can be disassembled and installed during maintenance. any of the columns without affecting the other columns. The rest of the structure of this embodiment is the same as that of Embodiment 1 and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com