Large-scale spatial free curved surface measurement method

A measurement method and curved surface technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of increasing costs, wasting resources, reducing efficiency, etc., and achieve the effects of good accuracy, high precision, and improved reliable basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

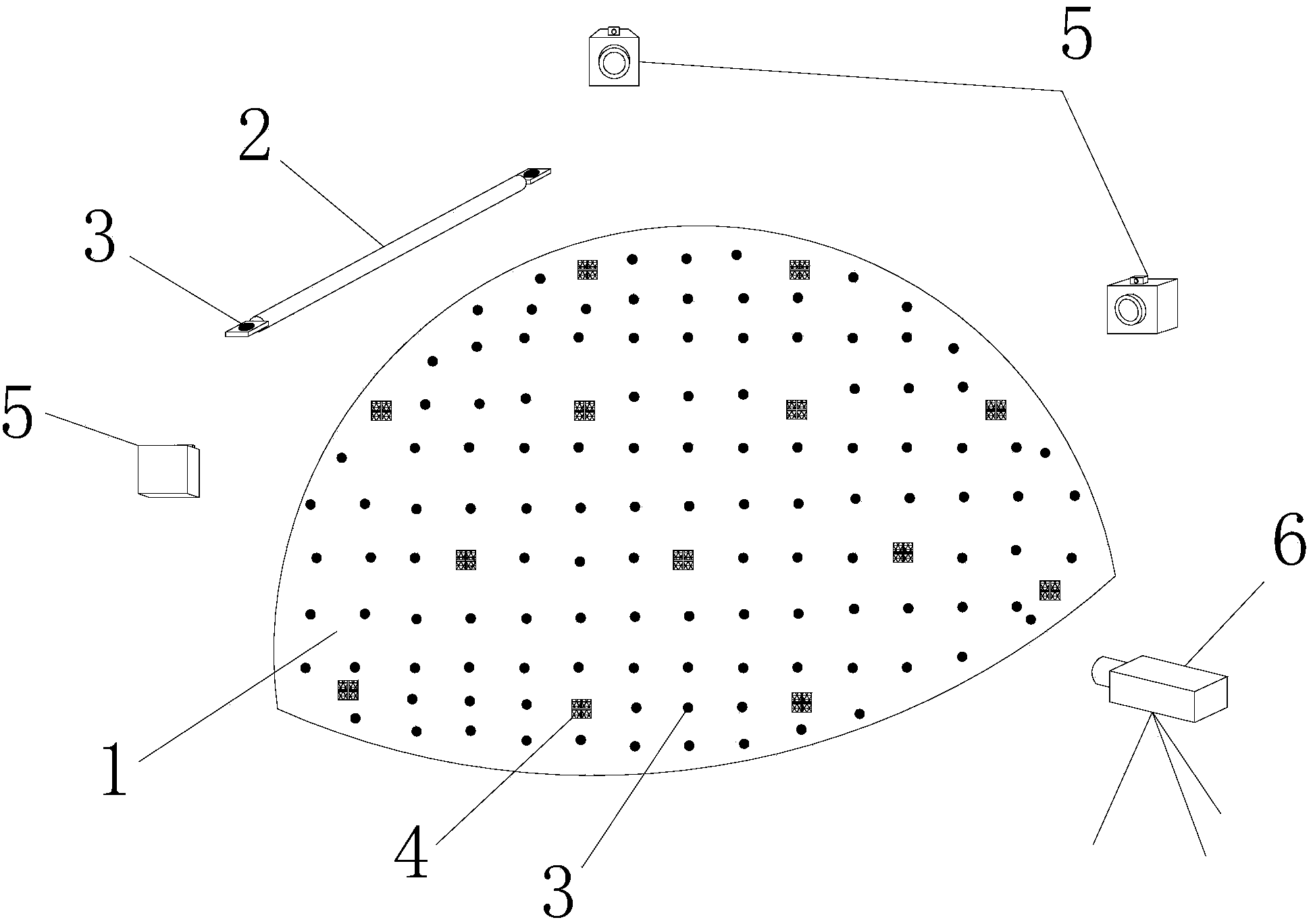

[0016] Such as figure 1 As shown, the preparatory work before measurement includes setting several measuring points 3 and coding points 4 on the measured surface 1. According to the area and the complexity of the shape of the measured surface 1, the number of setting measuring points 3 is also different. The general principle is that the measurement points 3 cover the entire curved surface 1, and the distribution is as uniform as possible. Since code point 4 is a mark used to distinguish the shooting area of each photo on surface 1, it is also a splicing point used to combine photos into a whole, so the setting of code point 4 should satisfy that at least 3 code point 4, and the same code point 4 appears in at least two different photos. A standard ruler 2 is set at a suitable position, and a measuring point 3 is also arranged on the standard ruler 2 , and the distance between the measuring points 3 on the standard ruler 2 is calibrated in advance.

[0017] Before measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com