Rock mass structure surface roughness evaluation method overcoming size effect

A technology of size effect and evaluation method, applied in measurement devices, instruments, optical devices, etc., can solve the problem of instrument manufacturing, portable use, test cost measurement time, greatly increased work intensity, technology is easily affected by external factors, feasibility It is not strong enough to achieve the effect of true and reliable evaluation results, reasonable measurement and evaluation costs, and overcoming technical difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of method for evaluating roughness of rock mass structural surface that overcomes size effect provided by the present invention, operates as follows:

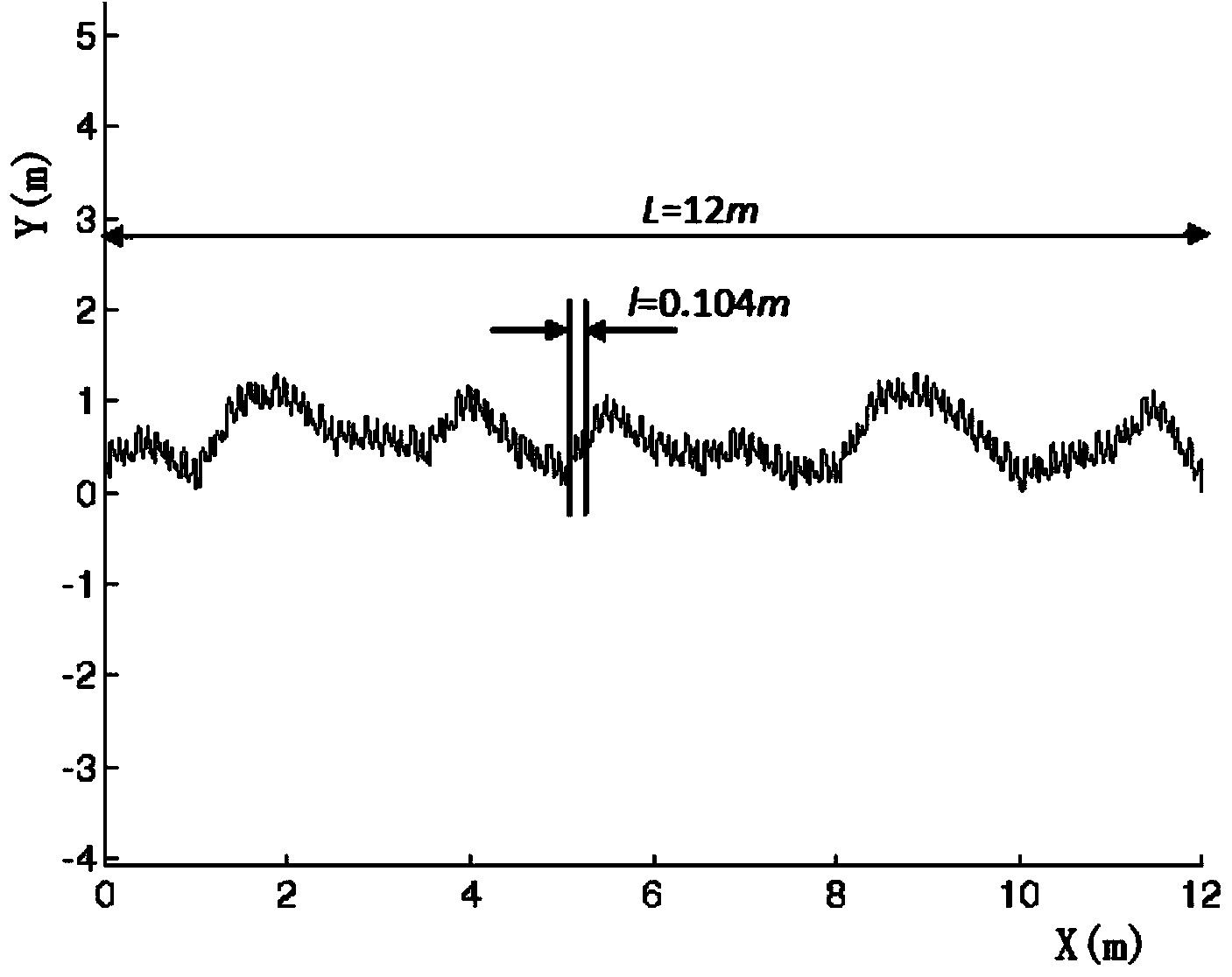

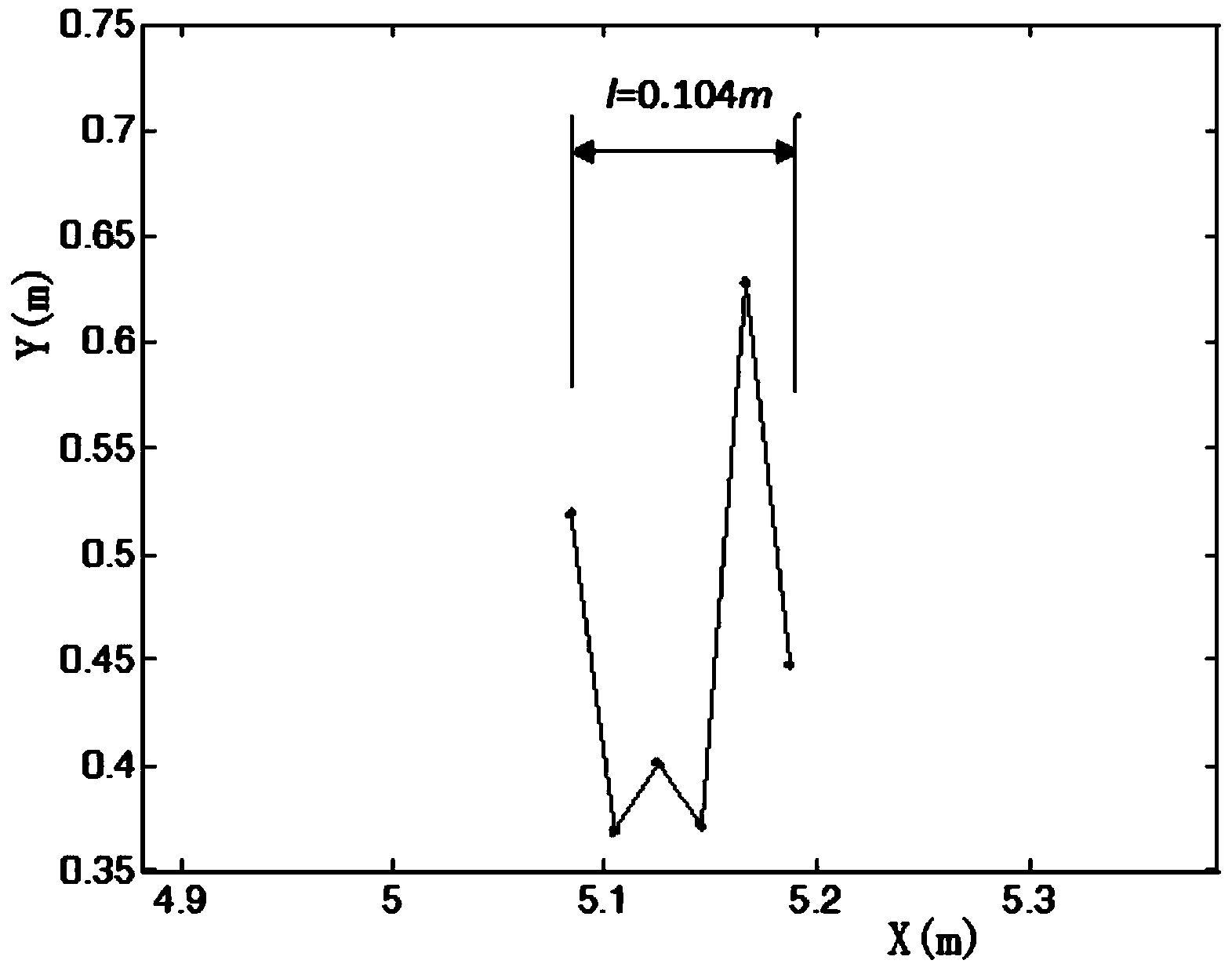

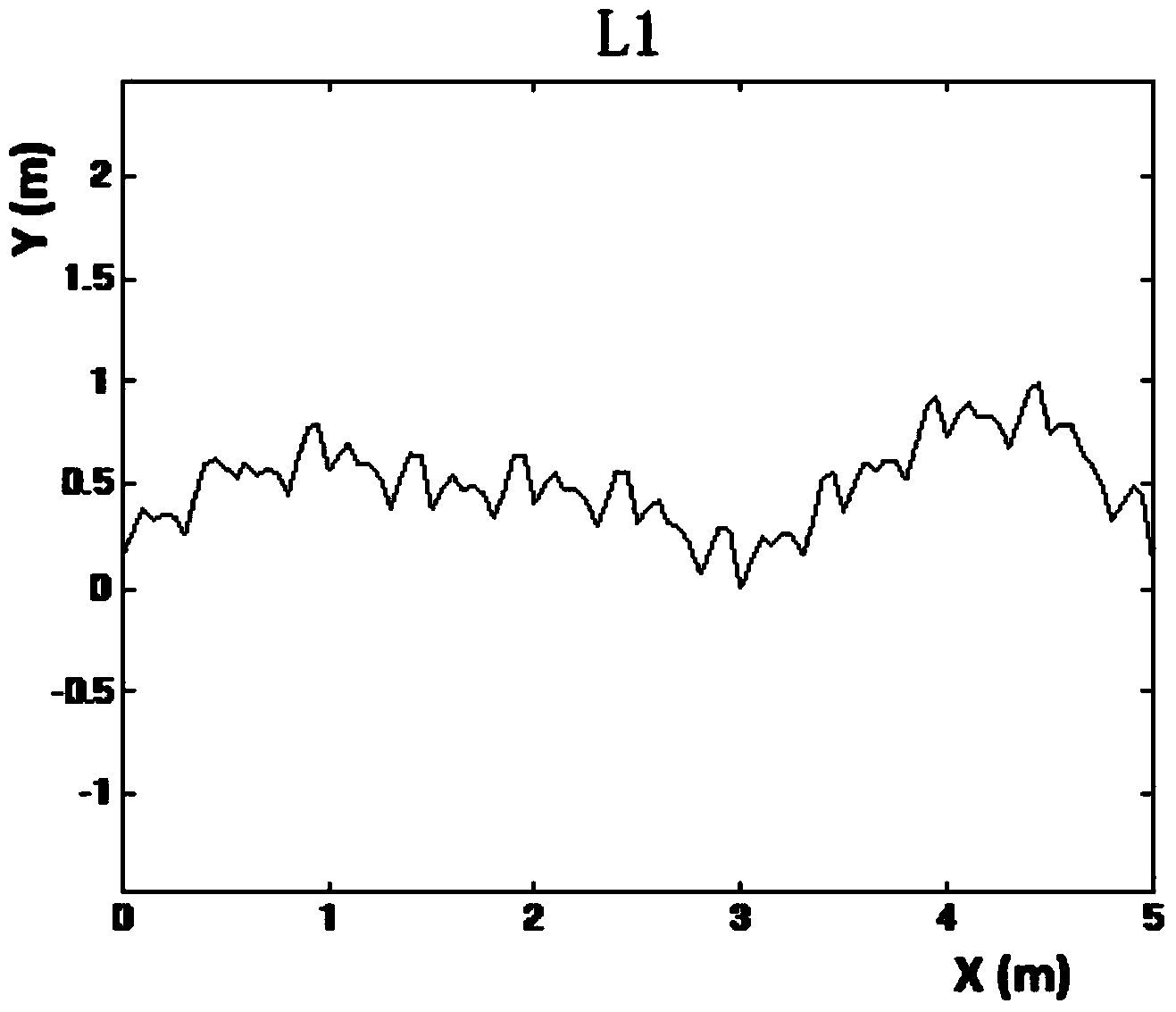

[0035] Step 1. Select a representative profile; figure 1 shown.

[0036](1) For the roughness evaluation of a large-scale rock mass structural surface in the field, it is required to select a natural rock mass structural surface that has not been disturbed by human activities. For example, rock mass structural surfaces formed by blasting and excavation are not within the scope of consideration. And the surface is not covered by vegetation, which is convenient for measurement.

[0037] (2) Select a representative large-scale section on the structural surface of the rock mass, and require that the section direction be consistent with the sliding direction of the potential rock mass or the direction of groundwater seepage, so that the roughness evaluation results can be used as a reference for the stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com