Method for evaluating reliability of performance state of reciprocating compressor

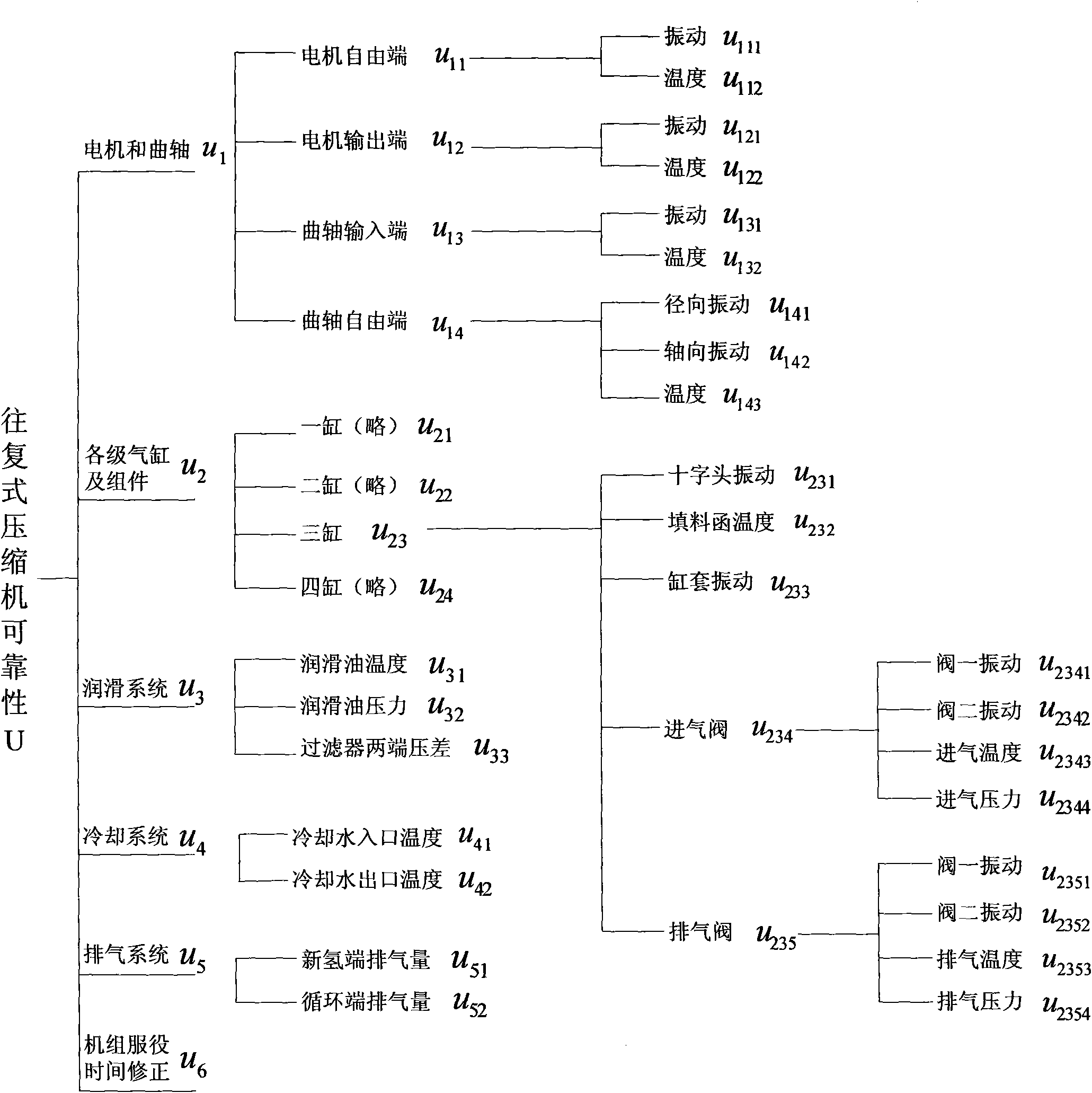

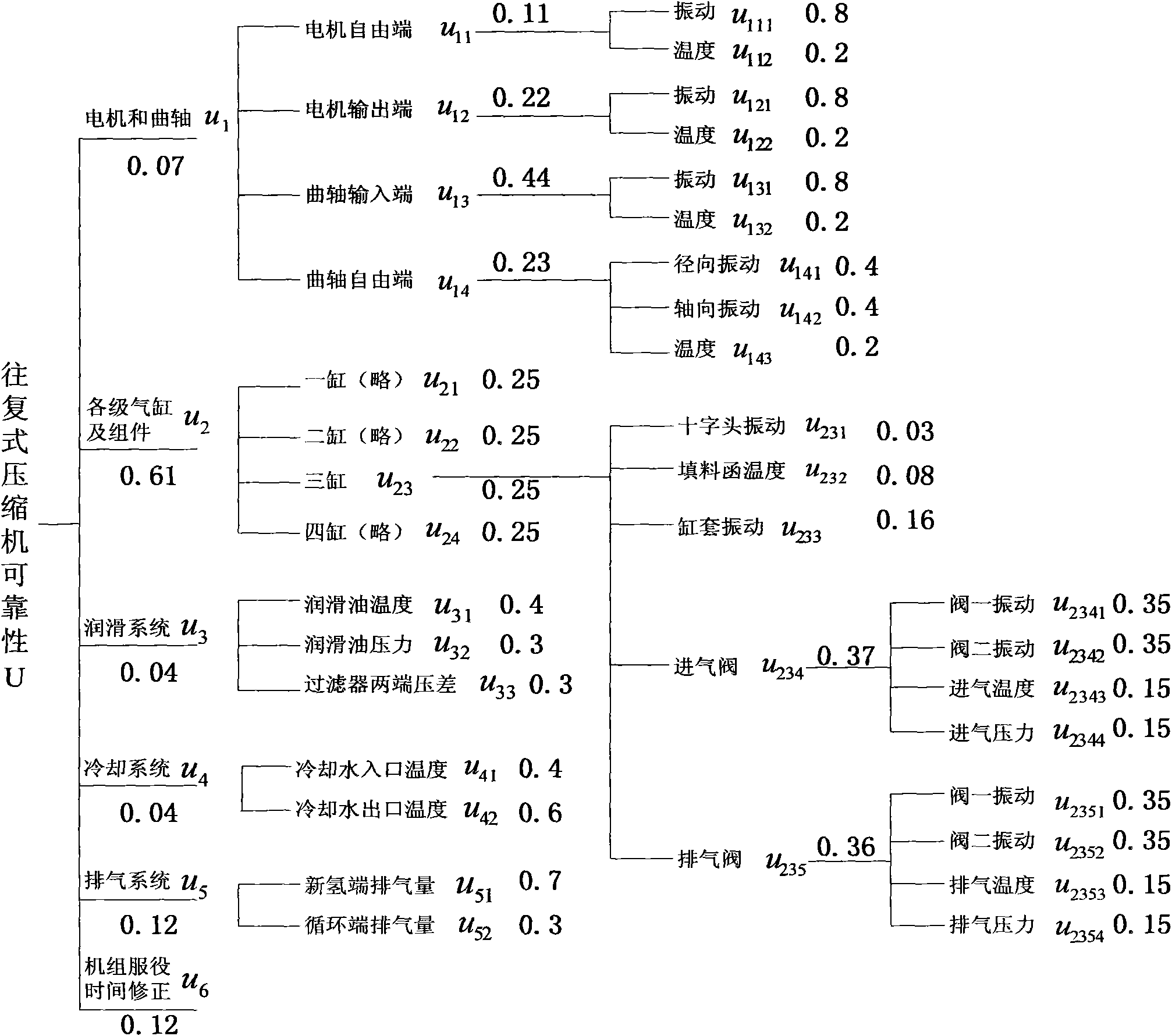

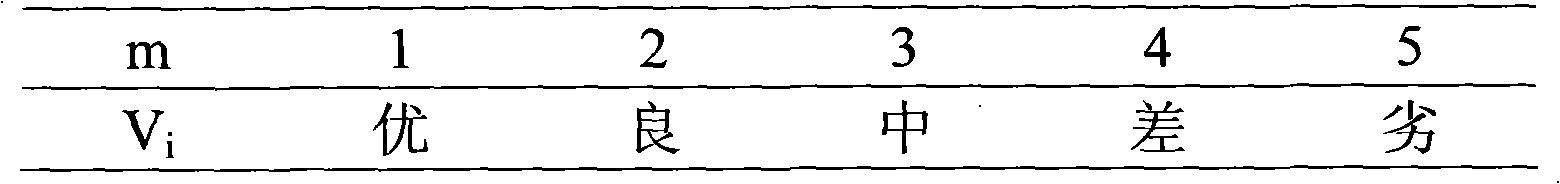

An evaluation method and compressor technology, which can be applied to liquid variable volume machinery, mechanical equipment, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The implementation method and effect of this method will be described below through the reliability evaluation of the performance state of the 1.2 million t / a diesel hydrogenation reciprocating compressor C-1101A of Lanzhou Petrochemical Company.

[0056]On March 4, 2009, we collected data on hydrogenation unit C1101A. When going to the site the next day, unit A shut down for maintenance. It was learned from the maintenance personnel that a positioning pin on the piston rod bracket of the 2 cylinder fell off, and fell into the buffer tank from the outlet valve of the 2 cylinder, causing a loud noise. The function of the locating pin is to radially locate the support tile, and has little effect on the work of the piston. However, for safety reasons, the maintenance personnel installed a new locating pin. We use the data collected on March 4, 2009 as the failure data to verify whether the failure of the unit components can be judged through the reliability evaluation.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com