A cylindrical pellet density measuring device and its measuring method

A technology for density measurement and pellets, applied in measuring devices, specific gravity measurements, instruments, etc., can solve the problems of damaging the surface of pellets, affecting the use of pellets, complicated operation, etc., and achieves simple operation, scientific data measurement, and low damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

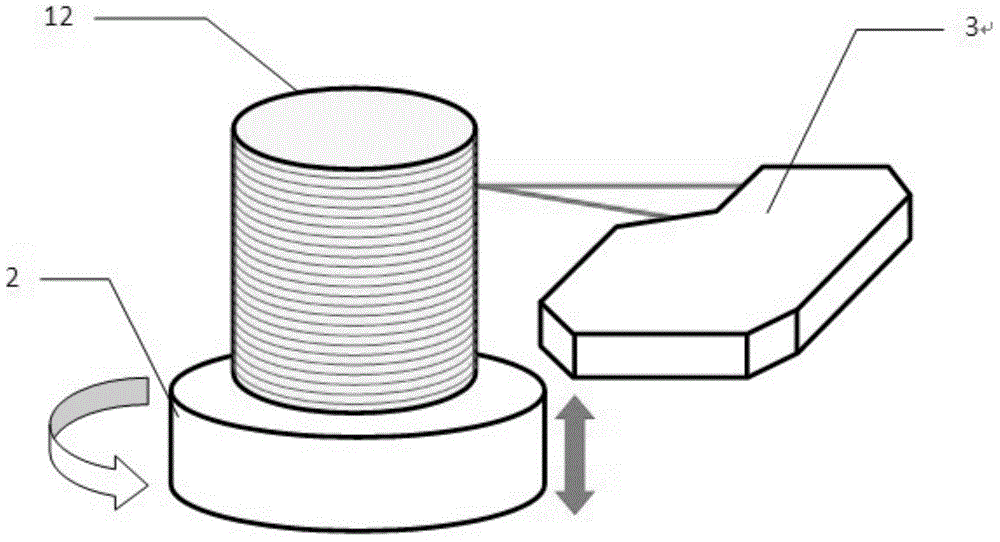

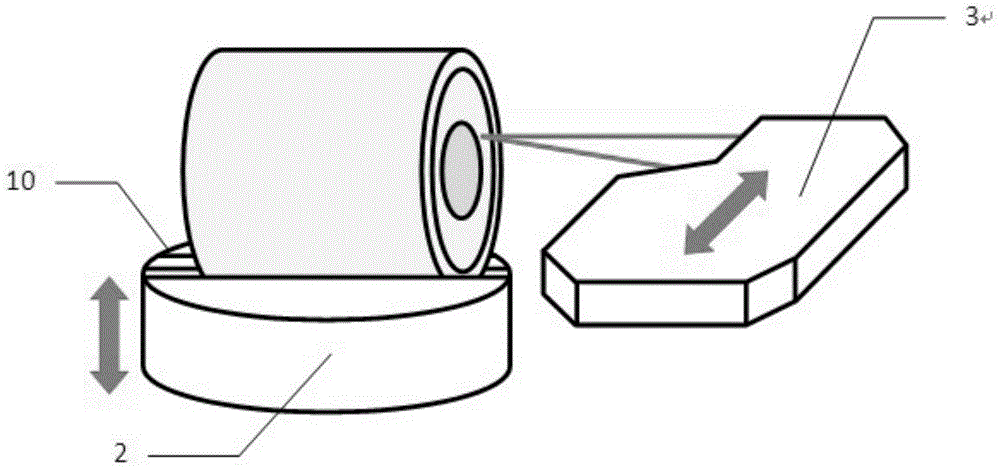

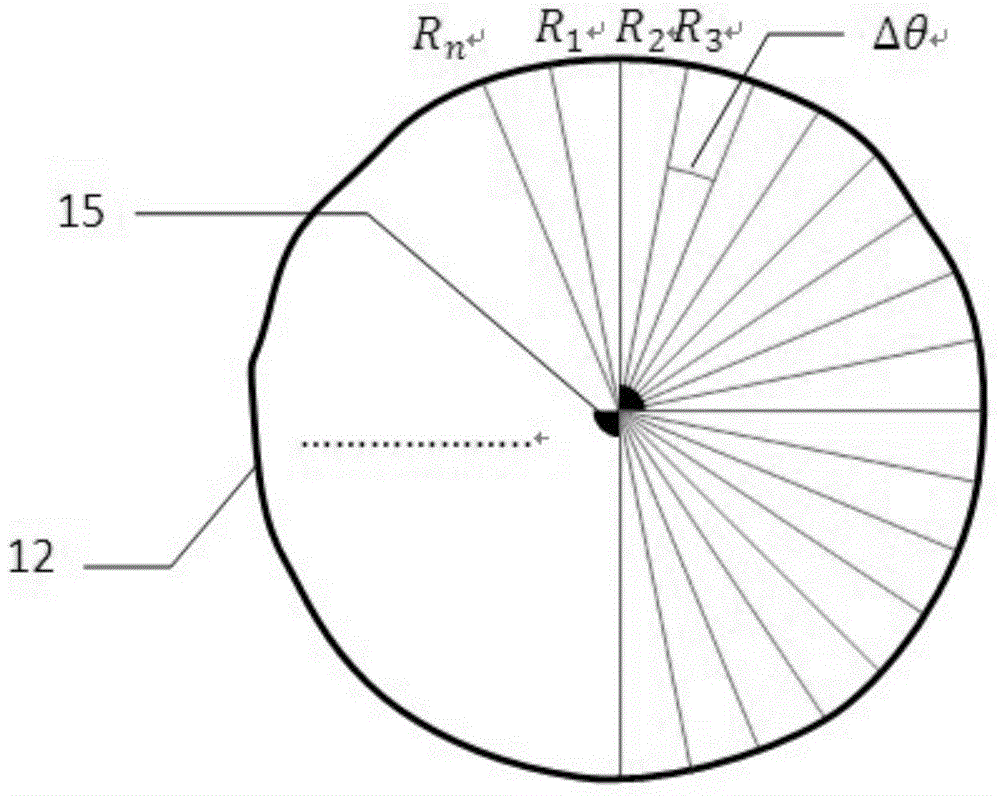

[0042] A device for measuring the density of cylindrical pellets, comprising: a vertical lifting platform 1, a precision rotary platform 2, a laser triangulation displacement sensor 3, a bottom platform 4, an electronic balance 5, and an industrial PC computer 6;

[0043] The vertical lifting table 1 is installed on the upper surface of the bottom table 4 and can be lifted in the vertical direction, and the precision rotary table 2 is installed on the vertical lifting table 1 and can rotate along its central axis, and can move in the horizontal direction. The laser triangulation displacement sensor 3 that moves is installed on the bottom platform 4 and is positioned beside the vertical lifting platform 1, and the electronic balance 5 is installed on the bottom platform 4;

[0044] The laser triangulation displacement sensor 3 and the electronic balance 5 are respectively connected to the industrial PC computer 6, the electronic balance 5 and the industrial PC computer 6 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com