A multi-layer aging system

A technology of aging boxes and elevators, which is applied to the analysis of materials and instruments, can solve the problems of taking up a lot of space, consuming a lot of time, product confusion, etc., and achieve the effects of improving space utilization, saving costs and materials, and saving manpower and materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

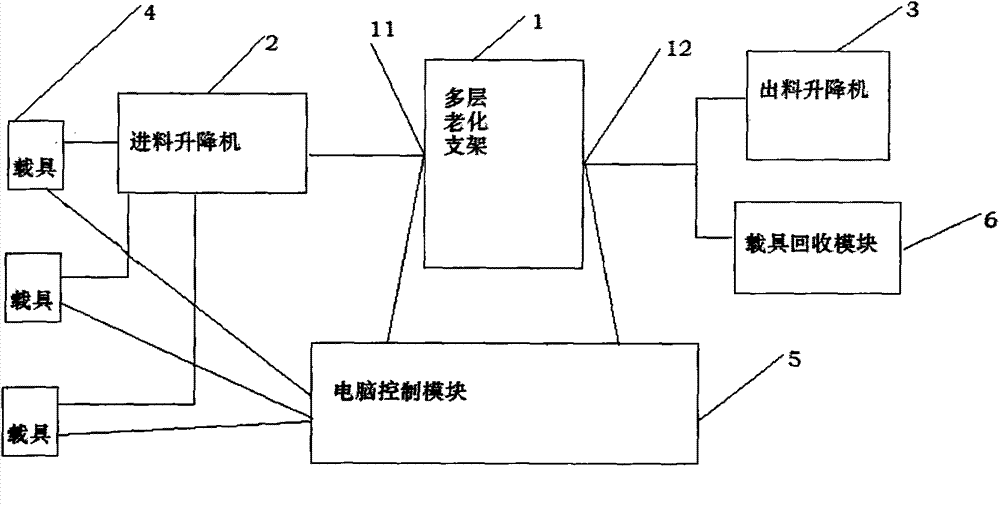

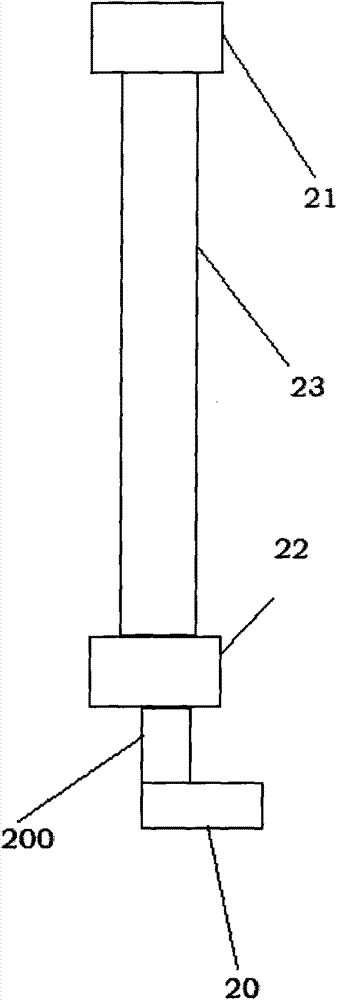

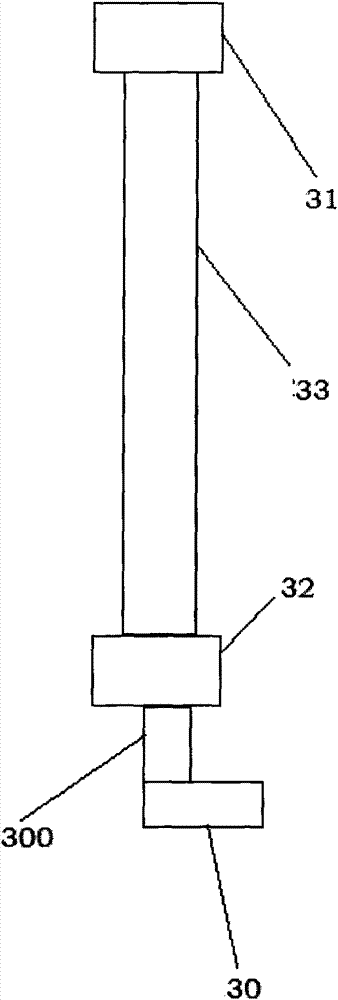

[0025] Such as figure 1 As shown, the present invention provides a multi-layer aging system, which includes a multi-layer aging support 1, a feed elevator 2, a discharge elevator 3, a plurality of carriers 4, a computer control module 5 and a carrier recovery module 6. The lifter 2 and the discharge lifter 3 are respectively arranged at the feed end 11 and the discharge end 12 of the multi-layer aging support 1, the carrier recovery module 6 is arranged at the discharge end 12 of the multi-layer aging support 1, and a plurality of carriers 4 An aging box 42 is arranged inside, and products to be aged are placed in the carrier 4. The multi-layer aging rack 1 includes 6 layers of racks, and the multiple carriers 4 are respectively sent to the multi-layer aging rack 1 by the feed elevator 2 from the feed end 11, and the aging After completion, the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com