Turbine main steam pressure operation curve and optimization method thereof

A technology of main steam pressure and operating curve, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

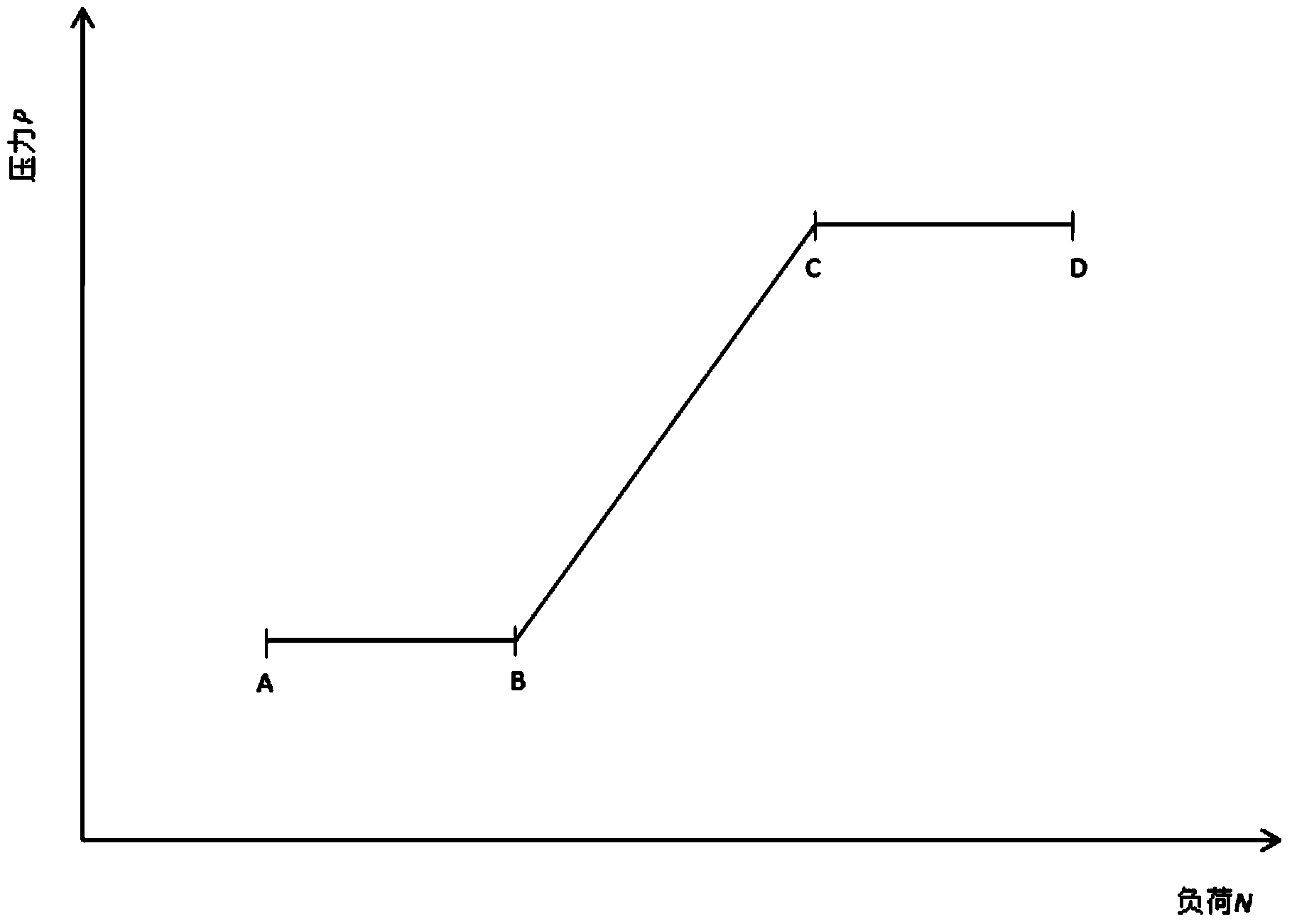

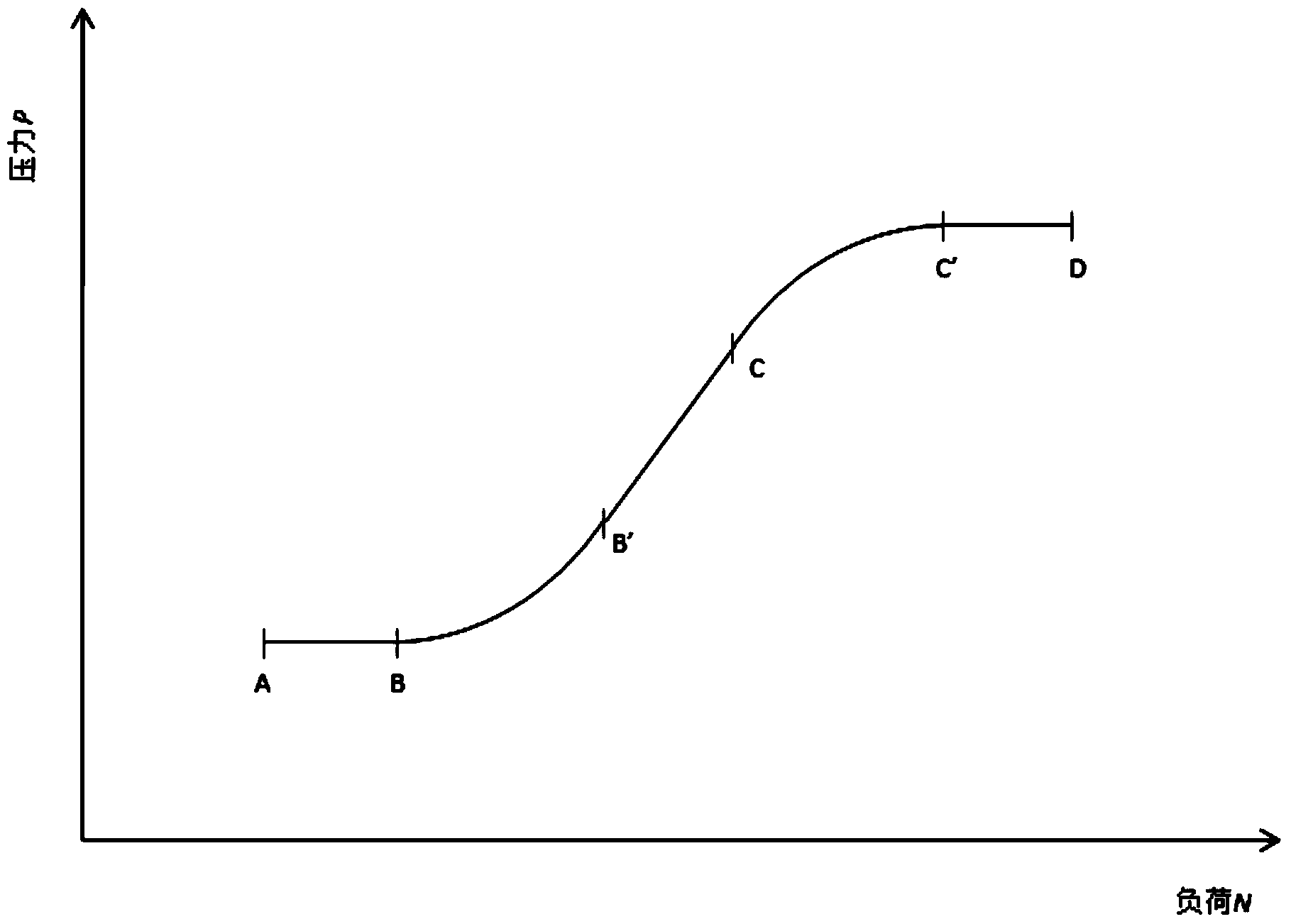

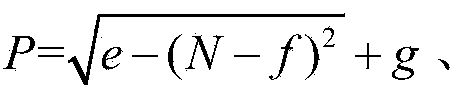

[0022] The present invention provides a main steam pressure operating curve of a steam turbine and its optimization method. The pressure operating curve includes a straight line section AB for low-load constant pressure operation, a straight line section B'C for mid-load sliding pressure operation, and a straight line section C for high-load constant pressure operation. 'D, and add a smooth transition arc segment BB' between the low load constant pressure operation straight line segment AB and the intermediate load sliding pressure operation straight segment B'C. A medium-to-high-load smooth transition arc segment CC' is added between the straight line segments C′D for high-load constant pressure operation, and the pressure operation curve is generally S-like (such as figure 1 shown).

[0023] In the technical solution of the present invention, according to the different characteristics of the unit and the operation optimization process of the unit, the operation curve of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com