A wideband cellular interlayer fiber reinforced plastic antenna cover

A glass fiber reinforced plastic radome and honeycomb interlayer technology, which is applied to the radiation unit cover and other directions, can solve the problems of insufficient strength of the radome, difficulty in waterproof treatment, influence of microwave signals, etc., and achieve good wave transmission performance and rigidity. The effect of good stiffness and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

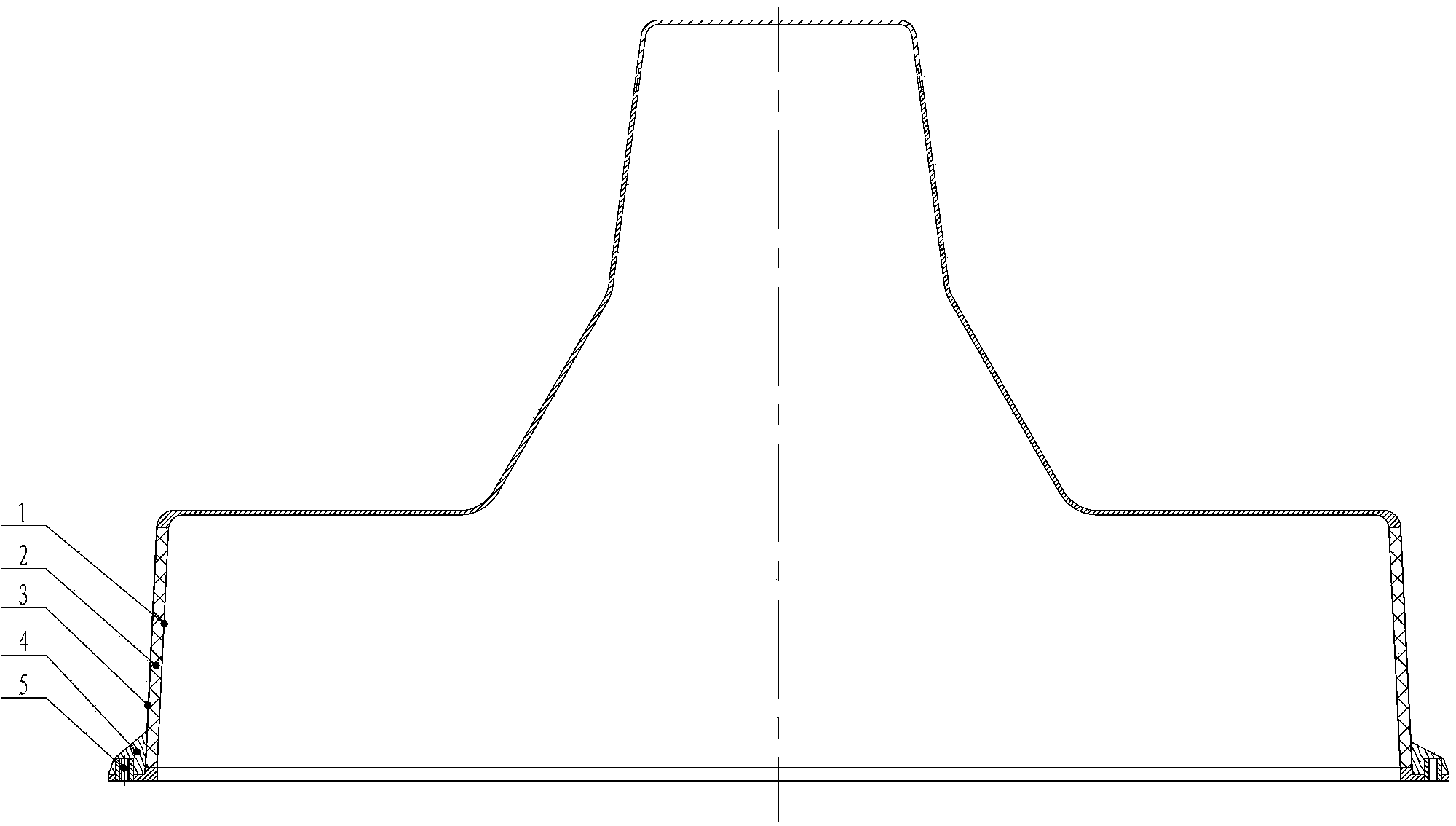

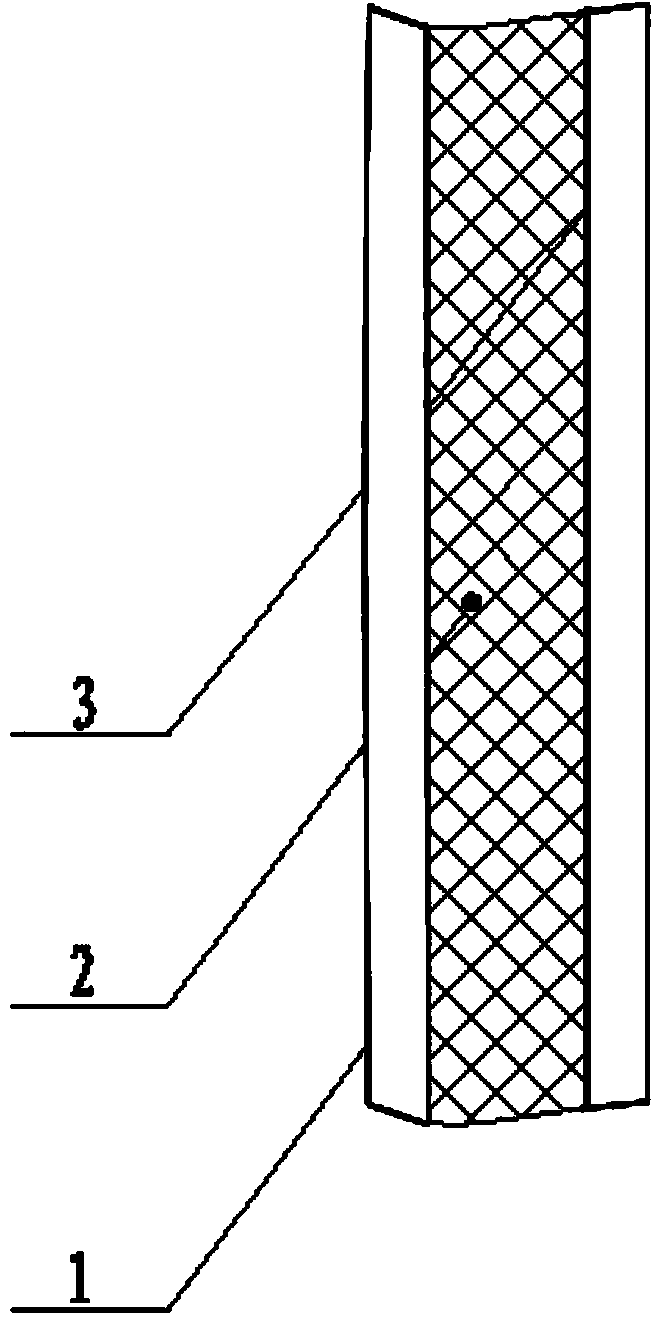

[0011] Such as figure 1 As shown, it includes an inner glass cloth 1, a honeycomb panel 2, a glass cloth 3, a reinforcing ring 4 and a plastic nut 5.

[0012] The inner glass cloth 1 and the honeycomb panel 2 are bonded together by resin glue, the glass cloth 3 is bonded on the outer layer to form a wave-transparent composite interlayer, and the radome installation interface is bonded with glass filaments to form a reinforcing ring 4. Plastic nuts 5 are pre-embedded in the reinforcement ring 4 .

[0013] In the invention, suitable honeycomb material is added to the inner layer of FRP at the circumferential position to ensure the wave-transmitting performance and rigidity of the radome in a wide frequency band. It overcomes the interference of the metal parts of the existing radome to the microwave, the insufficient strength and the narrow applicable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com