Oxygen barrier for packaging applications

A use, dispersion technology, applied in the direction of wrapping paper, transportation and packaging, hemicellulose coating, etc., can solve the problems that did not mention the influence of clay on permeability and/or mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] Materials and methods

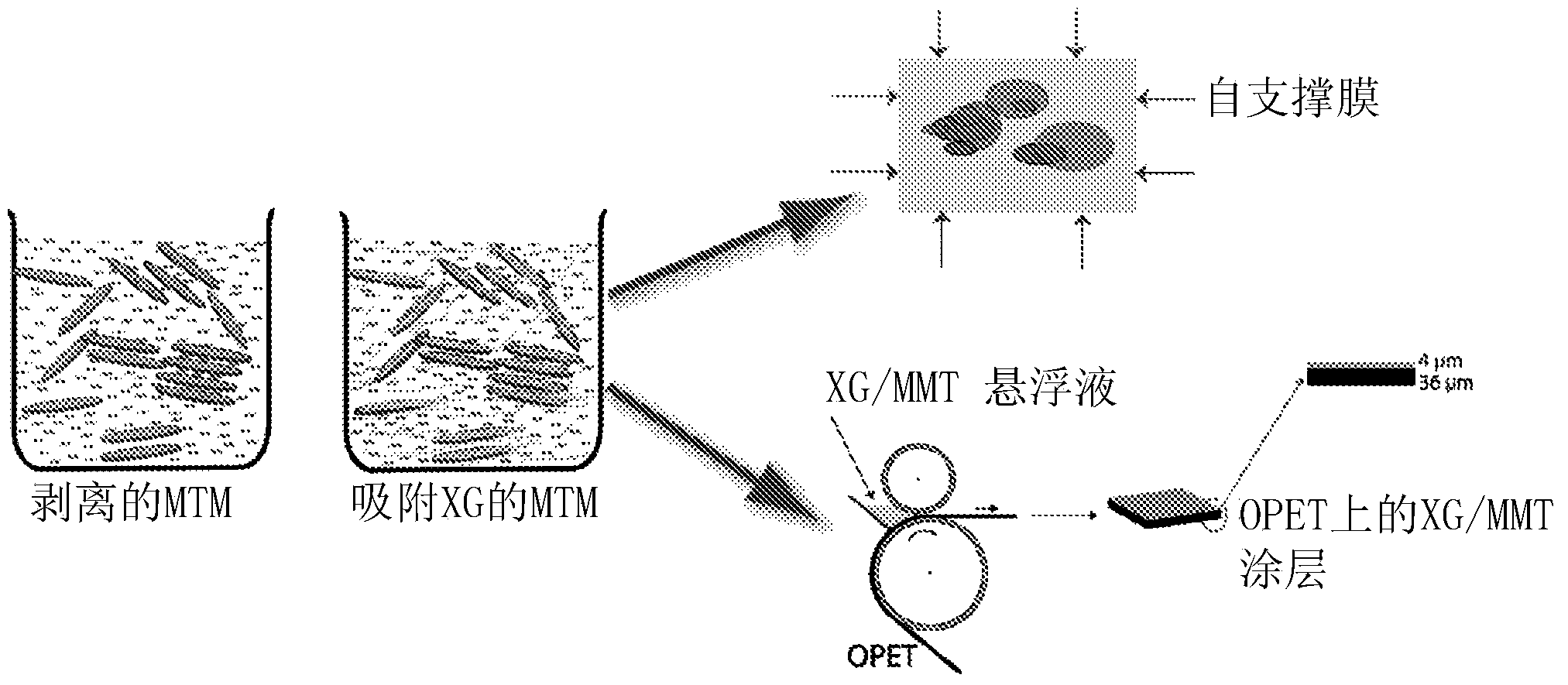

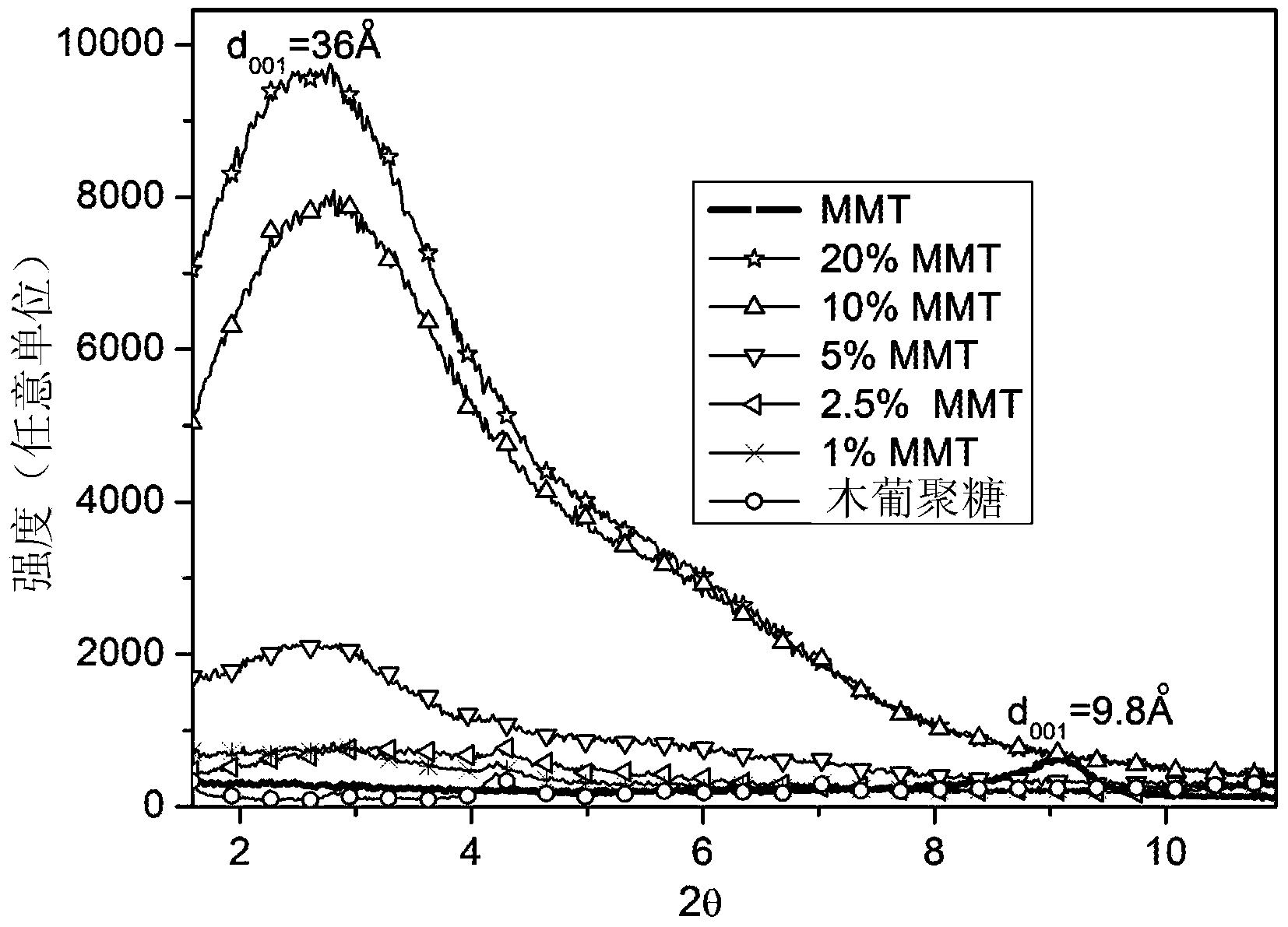

[0093] Preparation of xyloglucan-MMT (XG / MMT) nanocomposite membranes: Prepare 1% MMT (Cloisite Na+, density 2.86 g / cc, Southern Clay Products, Inc.) solution at ambient temperature by using Ultra Turrax stirrer (IKA, DI25Basic) was stirred at 25000 rpm for 15 minutes, followed by sonication at 37% amplitude using a Vibra-Cell (Sonics & Materials, Inc.) ultrasonic processor. This was repeated several times and the resulting solution was left undisturbed for 3 days to remove any clay lumps. Industrially available xyloglucan (weight average molecular weight, 2.5 MDa, Innovassynth technologies Ltd., India) was purified by centrifugation (4000 rpm, 45 minutes) and freeze-dried to obtain pure xyloglucan. 1.0, 2.0, 5.0, 10.0 and 20.0% (w / w) clay dispersants were added to the corresponding XG solutions and mixed using an Ultra thorax at 13500 rpm for 15 min and kept under magnetic stirring overnight. The resulting solution was centrifuged at 4000 rpm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com