Prefilling injector

A technology of prefilled syringes and cartridges, applied in the field of mechanical connection structures, can solve the problems of unfavorable popularization, lower costs, and higher thresholds for use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the accompanying drawings.

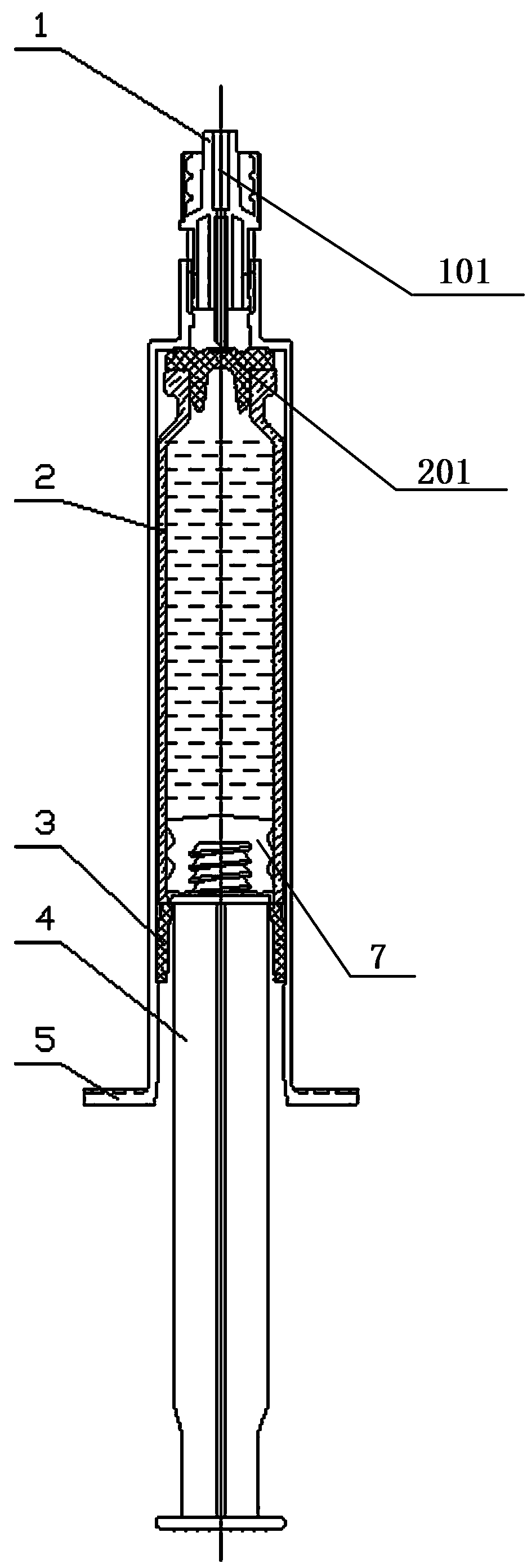

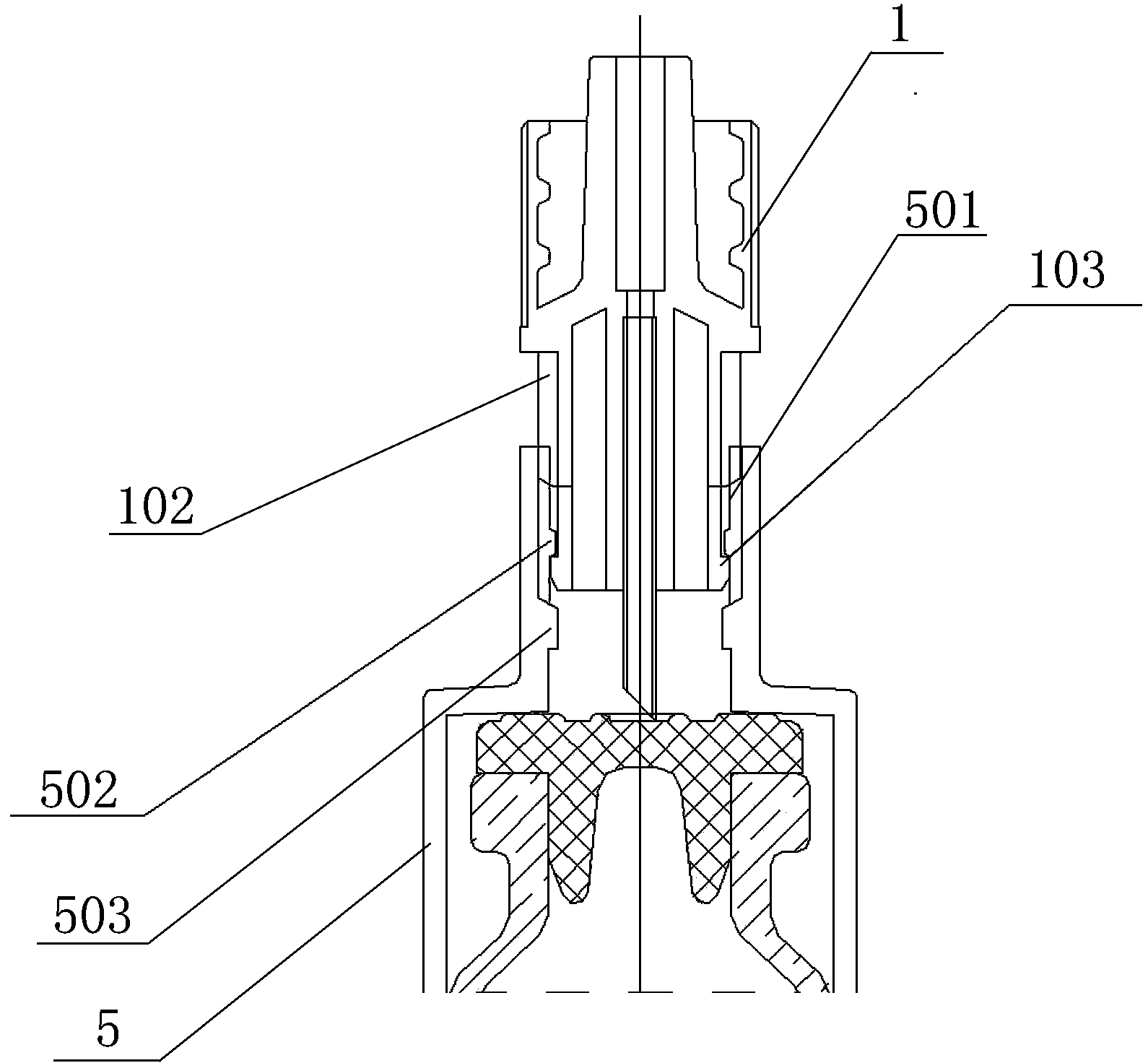

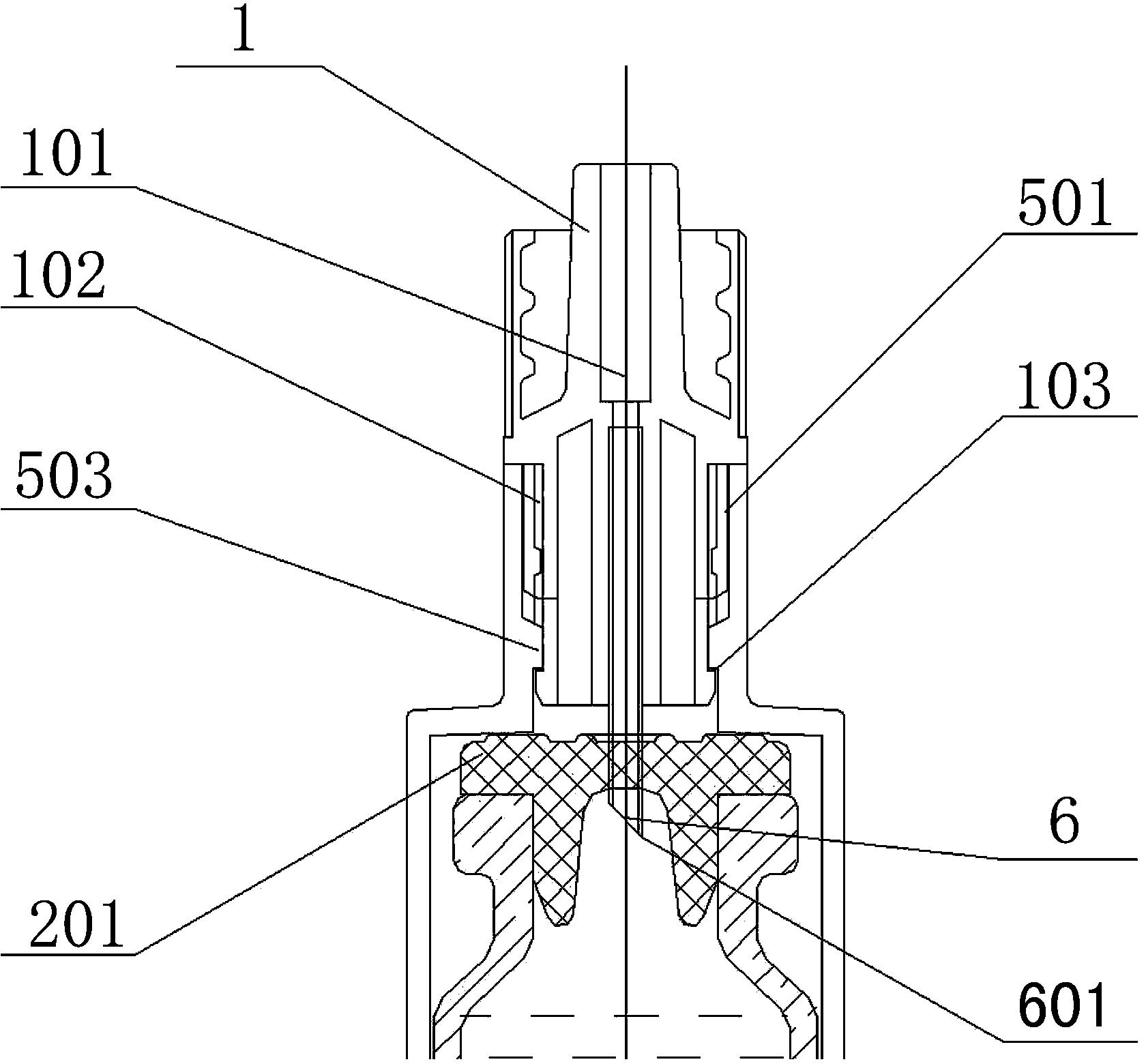

[0040] The present invention is a prefilled syringe. In the first embodiment of the patent of the present invention, it includes an outer sleeve 5, which is different from the prior art in that: the outer sleeve 5 is provided with a cartridge bottle 2, and the outer sleeve 5 The neck of the upper end is provided with a spiral seat 1, and the lower part of the spiral seat 1 is provided with a puncture needle 6. It protrudes from the lower part of the spiral seat 1 and is located in the neck of the outer sleeve 5. The free end of the puncture needle 6 forms a thorn point 601. The inner wall of the inner cavity of the outer sleeve 5 is provided with a fixed sleeve 3, and the upper end of the fixed sleeve 3 is against the clamping The lower end of the bottle 2, the rubber plug 7 at the upper end of the core rod 4 is located in the cavity near the lower end of the cartridge 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com