Agitator for mixing and stirring

A technology of mixing and stirring and stirring tank, which is applied in the field of stirring tank, can solve the problems of insufficient stirring and mixing, affecting the stirring effect, etc., and achieves the effect of good stirring effect and increasing effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

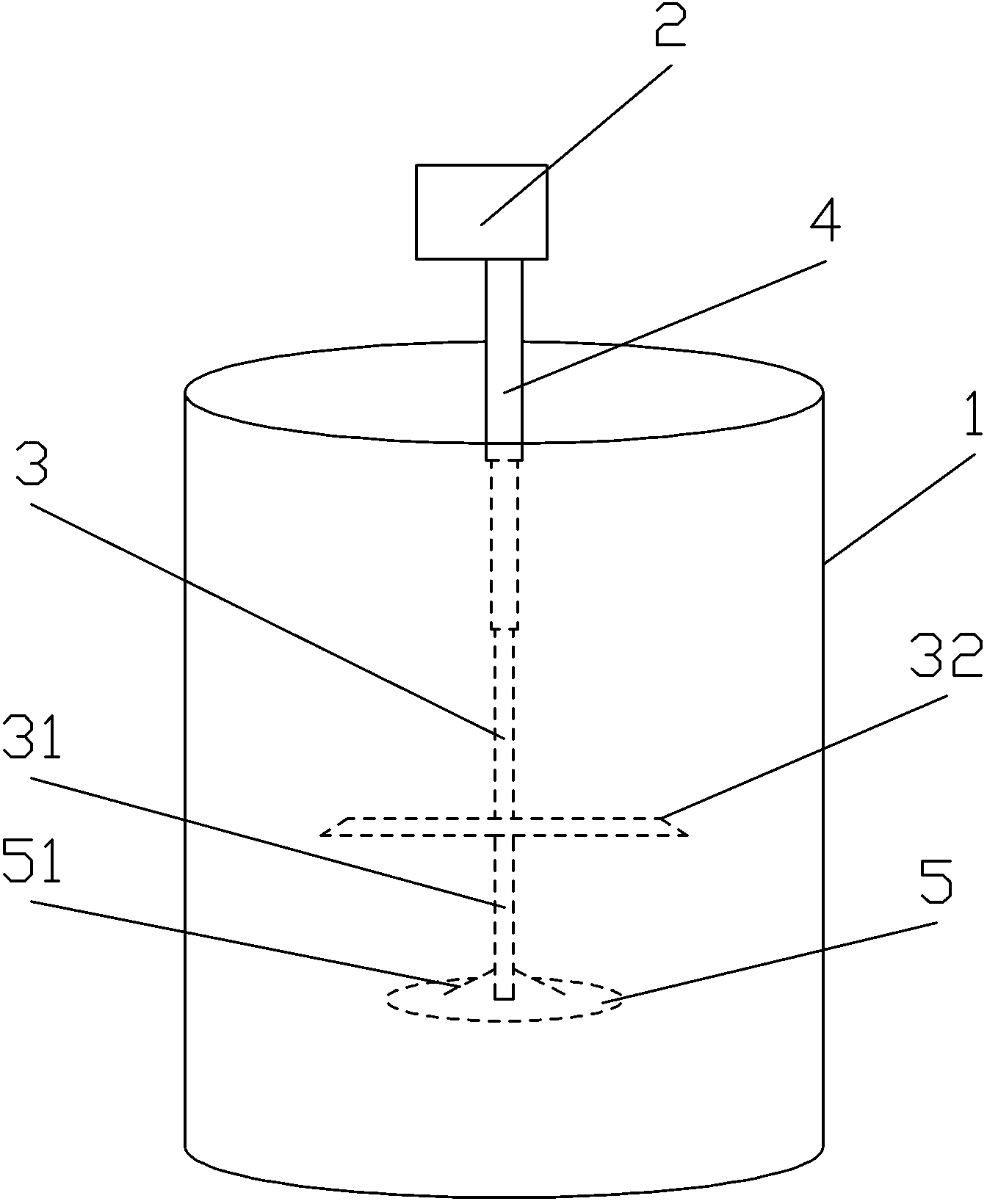

[0014] Such as figure 1 As shown, the present invention provides a stirring tank for mixing and stirring, including a tank body 1, a motor 2, and an agitator 3, wherein it also includes a telescopic rod 4, and one end of the telescopic rod 4 is connected to the power output end of the motor 2, and the telescopic rod 4 is connected to the power output end of the motor 2. The other end of rod 4 is connected with stirrer 3, and telescopic rod 4 is hollow structure, and motor 2 is connected with stirrer 3 by the inside of telescopic rod 4, and stirrer 3 comprises stirring shaft 31 and stirring paddle 32, and the lower end of stirring shaft 31 is arranged There is a horizontal disk 5, and the stirring paddle 32 is positioned above the horizontal disk 5. In addition, considering that many materials in the chemical industry are corrosive to a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com