Access door structure for mill

A technology for inspection doors and mills, which is applied in the field of mill equipment, can solve the problems of inconvenient opening and closing installation, complex structure, etc., and achieve the effects of avoiding waste and external pollution, good structural sealing, and convenient closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

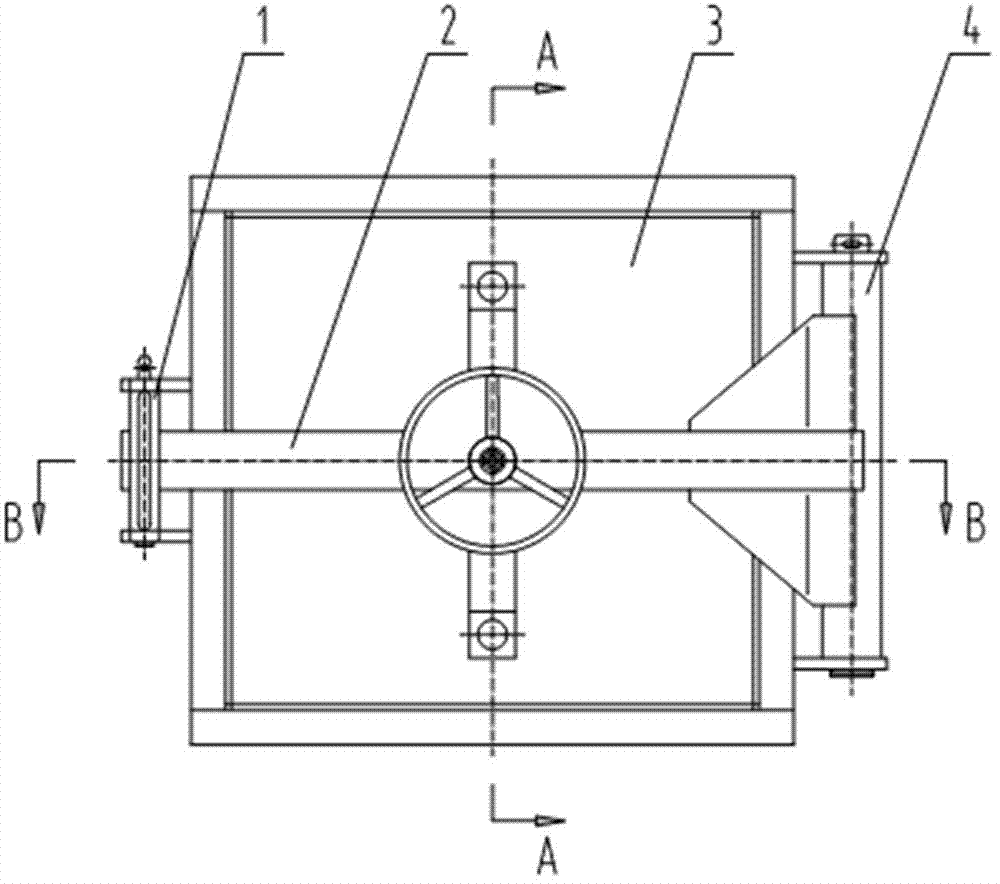

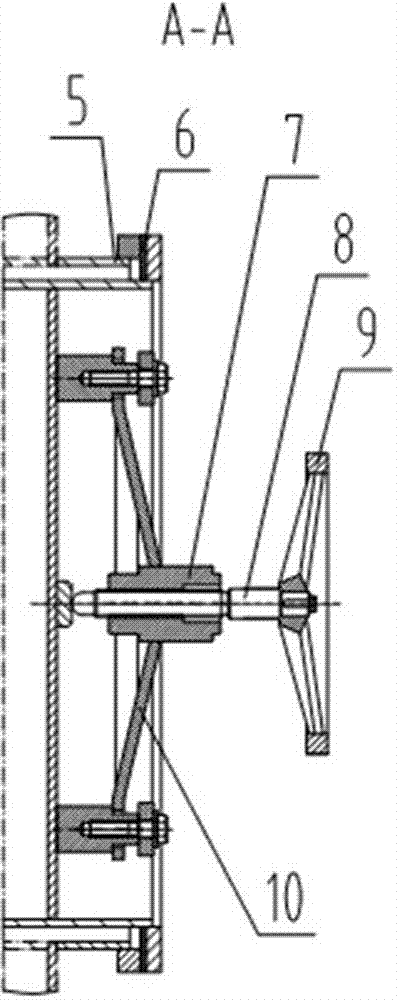

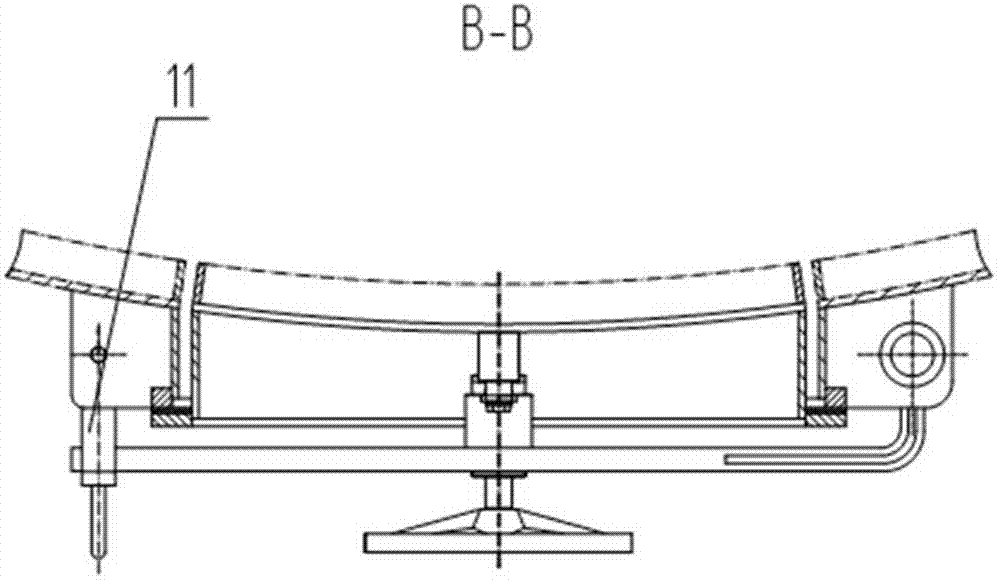

[0019] A mill inspection door structure, including a door frame 5, a door cover 3, a door bolt 11, a pin shaft 1, a door shaft 4, a pressing rod 2 and a pressing device, the door frame 5 is welded on the outer wall of the mill, and the door frame 5 is a The side is provided with a door frame connection hole, and the door frame connection hole is provided with a door shaft 4 that fits with the gap. The door shaft 4 can rotate in the door connection hole, and the upper end of the door shaft 4 is provided with a cotter pin to prevent the door shaft 4 from falling off. 2 One end is hinged with the door frame 5 through the door shaft 4, the middle of the pressure rod 2 is connected with the door cover 3 through a pressing device, the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com