Electromagnet mechanism type centrifugal machine door lock

An electromagnet and centrifuge technology, applied in the field of door locks, can solve problems such as personal injury and non-compliance with the safety operation requirements of the centrifuge, and achieve the effect of avoiding injury and ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

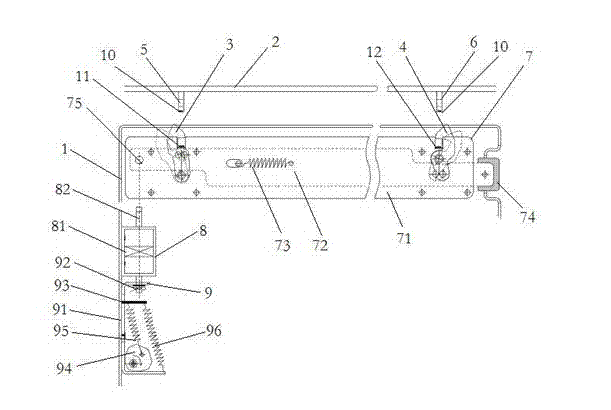

[0017] In order to improve the control degree of the automatic locking mechanism 7, a magnetic column 10 can be installed at the bottom of the left / right deadbolt 5,6, and a hook sensor 11, which is opposite to the magnetic column 10, is installed on the left / right hook 3,4. 12. The hook sensors 11 and 12 are connected with the control system signal of the centrifuge.

[0018] When the magnetic column 10 is close to the hook sensors 11, 12, the output of the hook sensors 11, 12 changes from high level to low level under the action of the magnetic field. When the machine detects that the hook sensors 11 and 12 all become low level, it shows that the door cover has been fully closed now.

Embodiment 2

[0020] In order to ensure that the door cover 2 can be safely opened after an accidental power failure during centrifugal operation, the technical solution of this embodiment is to provide a manual toggle hole on the eccentric wheel 94 .

[0021] Accidental power failure during centrifugal work, iron core 82 positions remain unchanged, elastic push plate 72 still can not promote, and door cover 2 keeps locking. Only after the centrifuge stops running completely, use a special tool to rotate the eccentric wheel through the manual toggle hole, so that the movable bracket 91 drives the iron core 82 to move in the opposite direction, and the head of the iron core 82 withdraws from the limit hole 75, then the door cover 2 can be moved. Safe open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com