Automatic screw locking device based on computer vision

A computer vision and automatic lock technology, applied in the electrical field, can solve problems such as manufacturing precision deviation, locking failure, etc., and achieve the effect of independent control lines, tight coordination, and easy inspection of faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

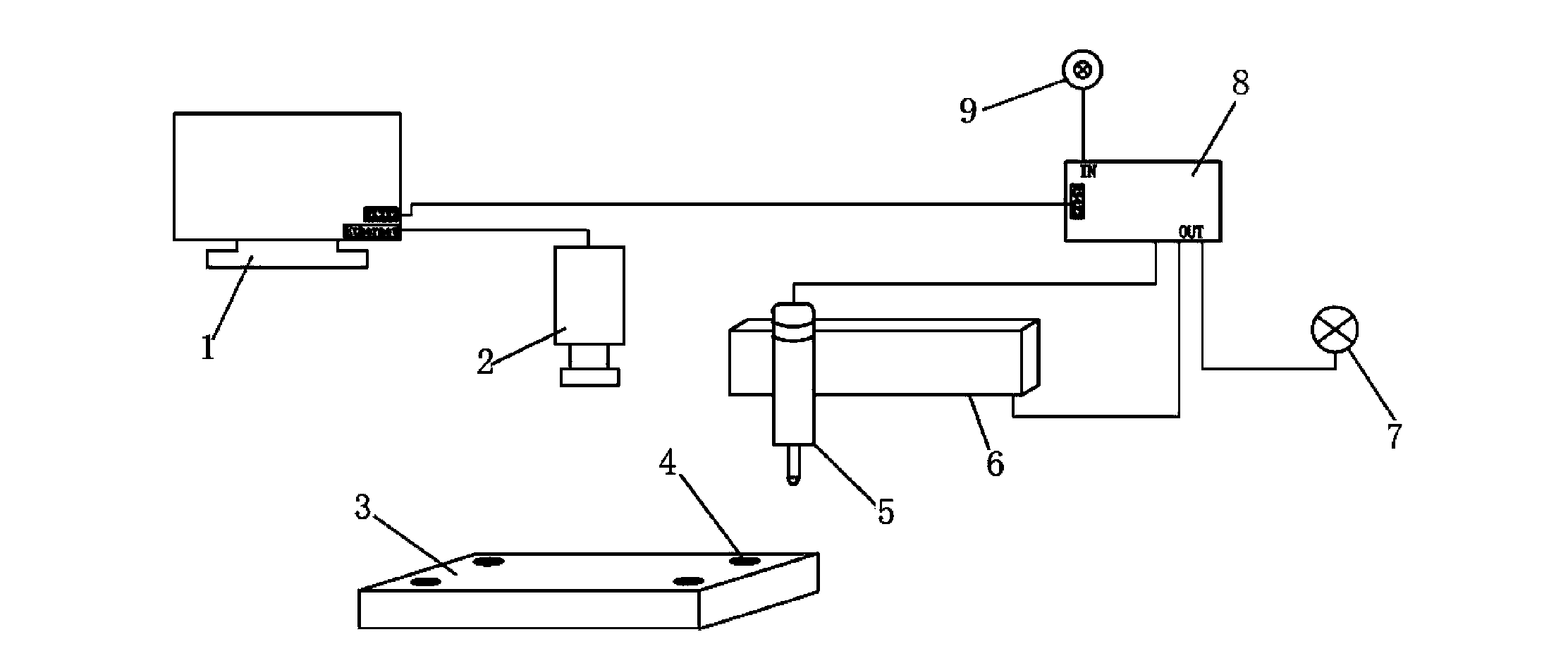

[0015] like figure 1 As shown, a computer vision-based automatic screw locking device of the present invention includes an industrial computer 1, an industrial camera 2, an electric screwdriver 5, a three-axis positioning device 6, a programmable controller 8 and an equipment rack (not shown in the figure ), wherein the three-axis positioning device 6 is arranged in the equipment rack, the electric screwdriver 5 is connected to the three-axis positioning device 6, the control end of the three-axis positioning device 6 and the electric screwdriver 5 The control terminals are respectively connected to the programmable controller 8, the programmable controller 8 is connected to the industrial computer 1 through the communication interface, and the industrial camera 2 is connected to the industrial computer 1.

[0016] Further, the industrial camera 2 is connected to the industrial computer 1 through an Ethernet network.

[0017] Further, a positioning jig (not shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com