General rubber extrusion head

A general-purpose extruder head technology, which is applied in the field of general-purpose rubber extruder heads, can solve the problems of time-consuming and labor-intensive replacement of extruder heads, lower production efficiency, and high production costs, and achieve simple structure, improved production efficiency, and The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

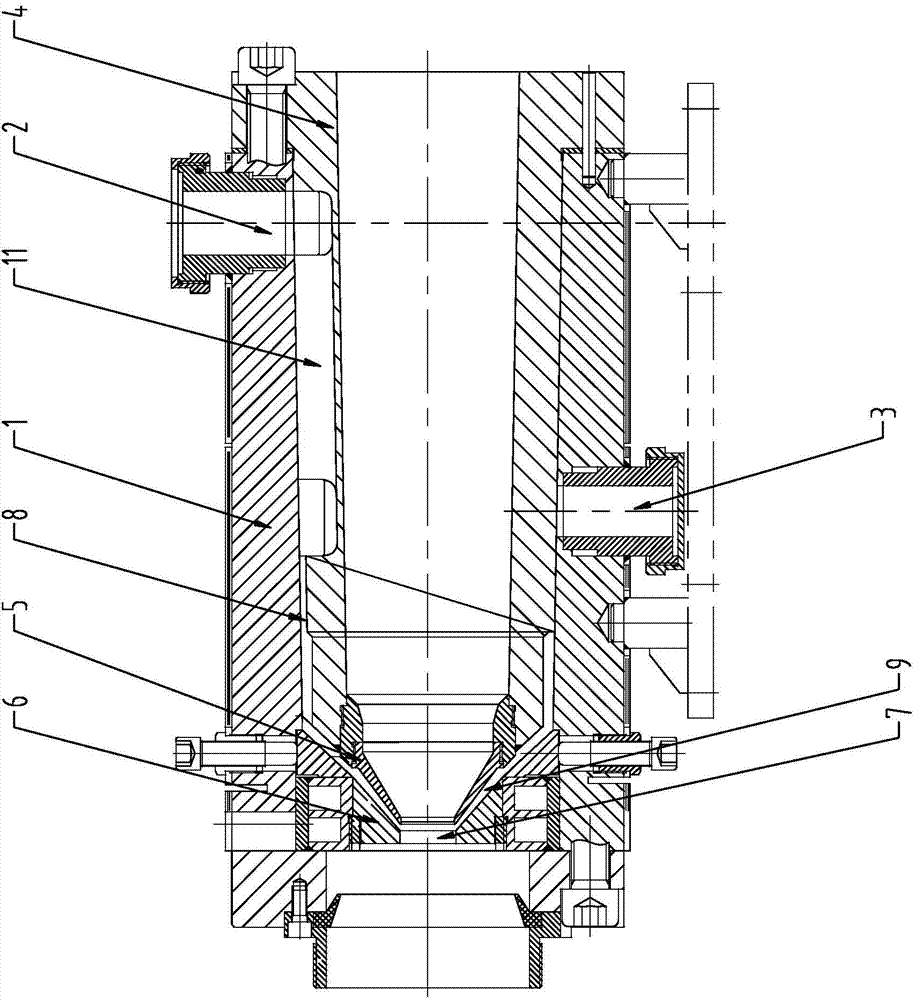

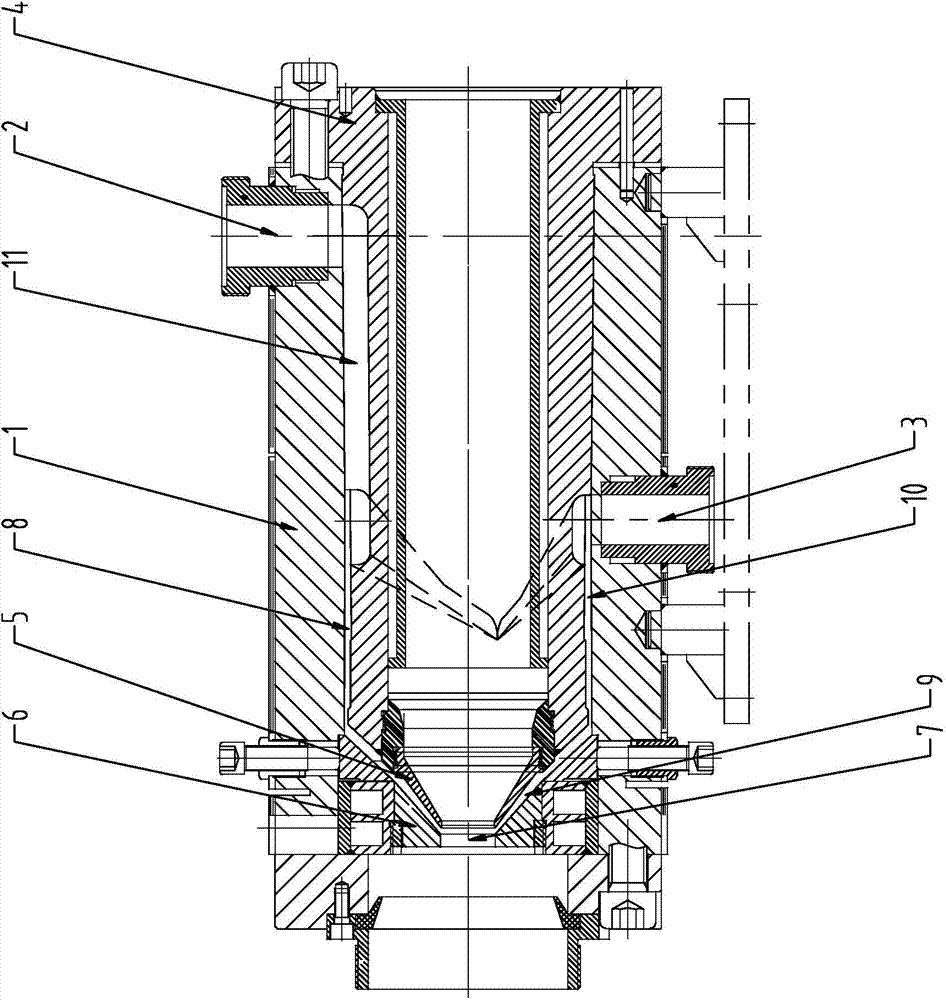

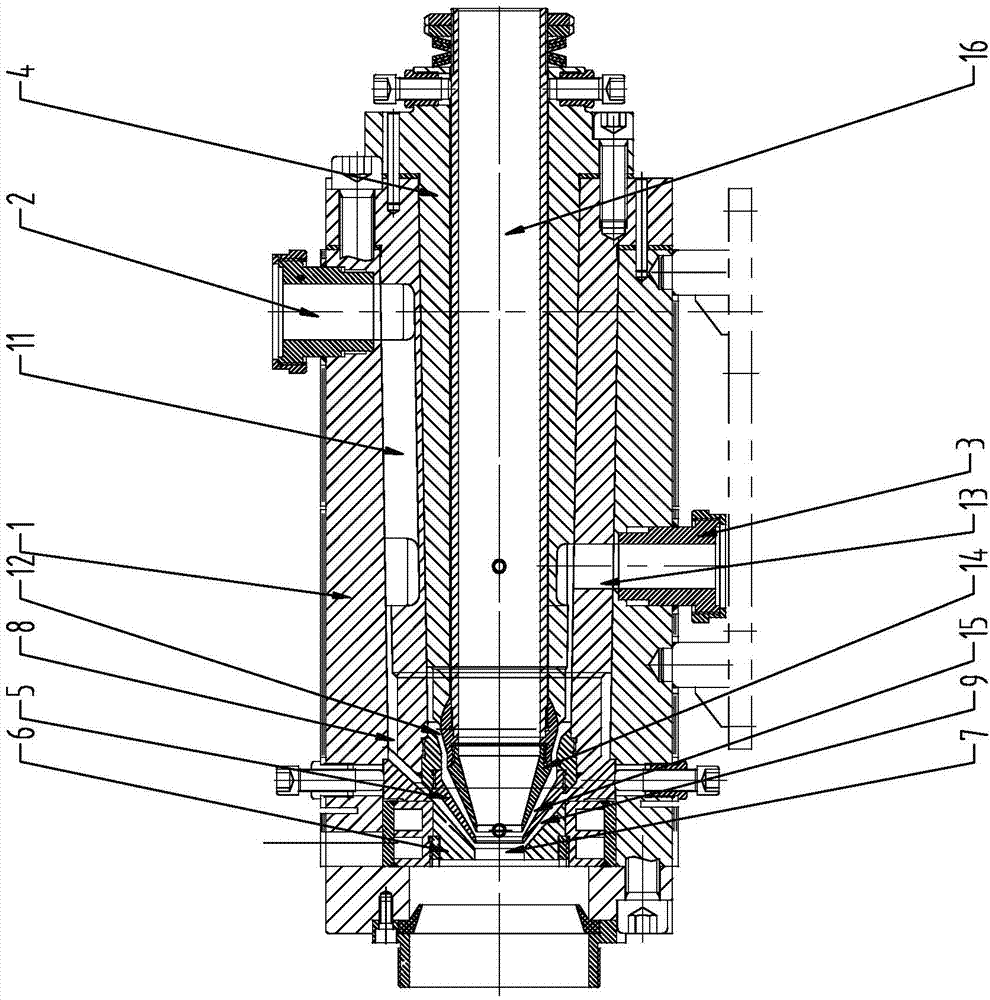

[0019] The present invention mainly includes a head body 1, in which a fluid chamber 8 is arranged, and an upper glue inlet 2 and a lower glue inlet 3 communicated with the fluid chamber 8 are arranged on the outer surface of the head body 1 .

[0020] The fluid cavity 8 is slidingly installed with the sub-fluid 4, and the front end of the sub-fluid 4 is connected with the mold core 5, and the mold core 5 is a cone.

[0021] The front end of the die body 1 is connected to the die opening 6, and the inside of the die opening 6 is provided with an extrusion cavity 9 matched with the core 5, and the extrusion cavity 9 is a tapered cavity. The center of the die opening 6 is provided with a glue outlet 7 .

[0022] Such as figure 1 As shown, when it is necessary to realize single-layer single-color rubber extrusion, an upper glue groove 11 is provided at ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap