Method for cooling a mould by circulating a heat-transfer fluid in contact with the external face thereof

一种传热流体、外表面的技术,应用在家里用具、其他家里用具、家用元件等方向,能够解决复杂、传热流体回路的模具昂贵实现等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the remainder of the specification, elements having the same structure or similar functions will be denoted by the same reference numerals.

[0034] In the remainder of the specification, the following directions will be used without limitation:

[0035] - longitudinal, indicated by arrow "L" and oriented from rear to front;

[0036] - vertically, indicated by an arrow "V" and oriented upwards from the bottom;

[0037] - Transverse, indicated by arrow "T" and oriented from left to right.

[0038] Additionally, the terms "axial" and "radial" will be used with reference to the axis "A".

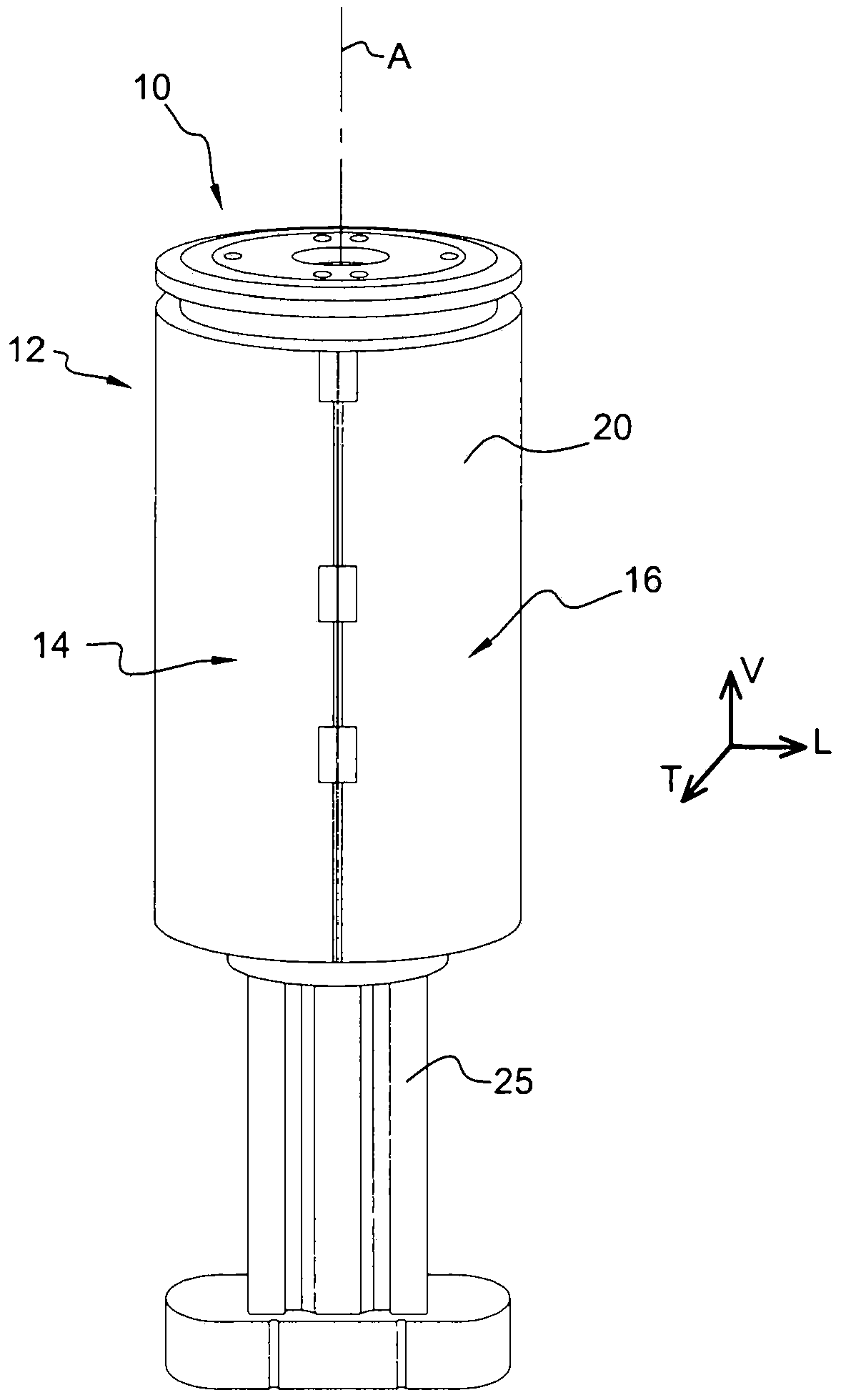

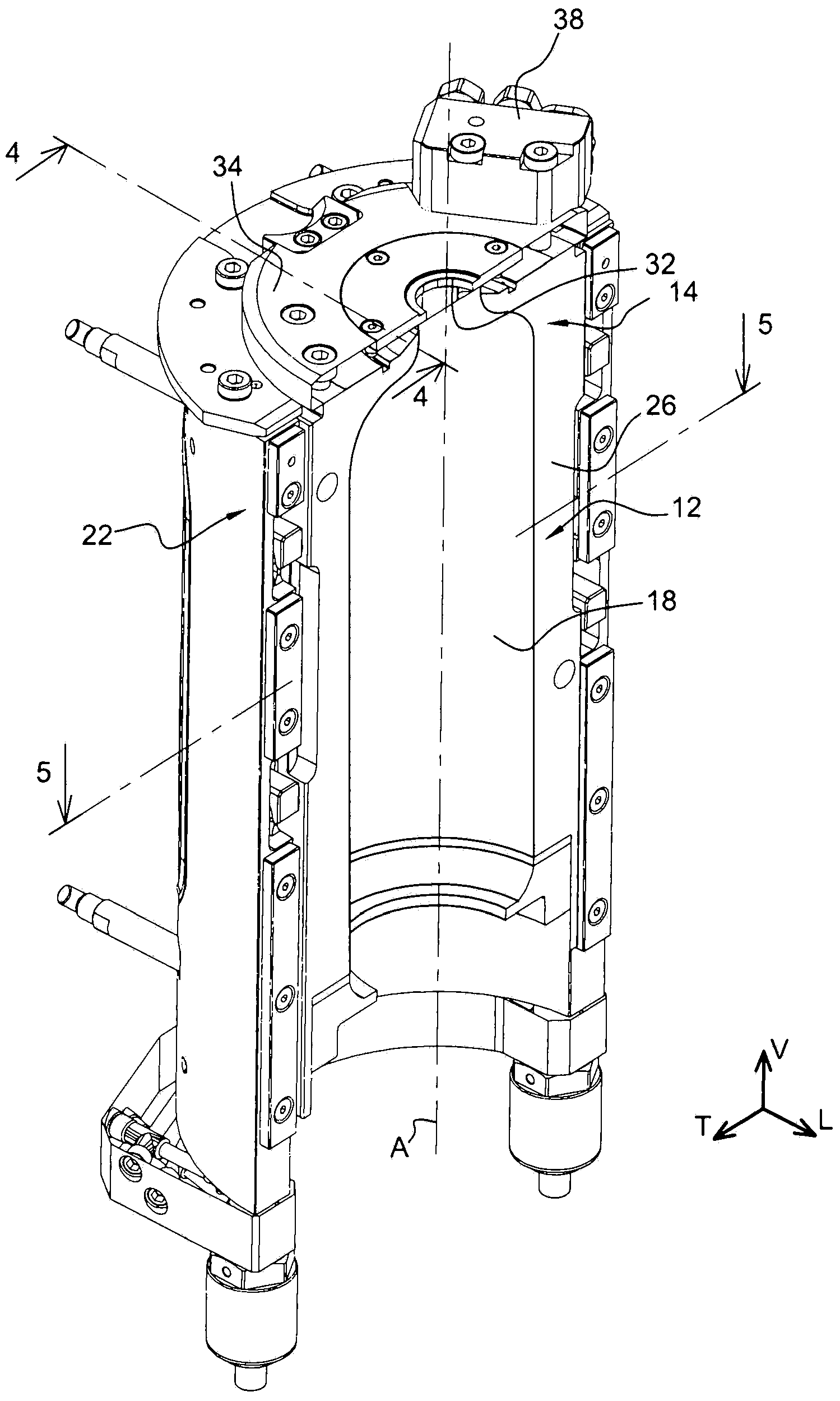

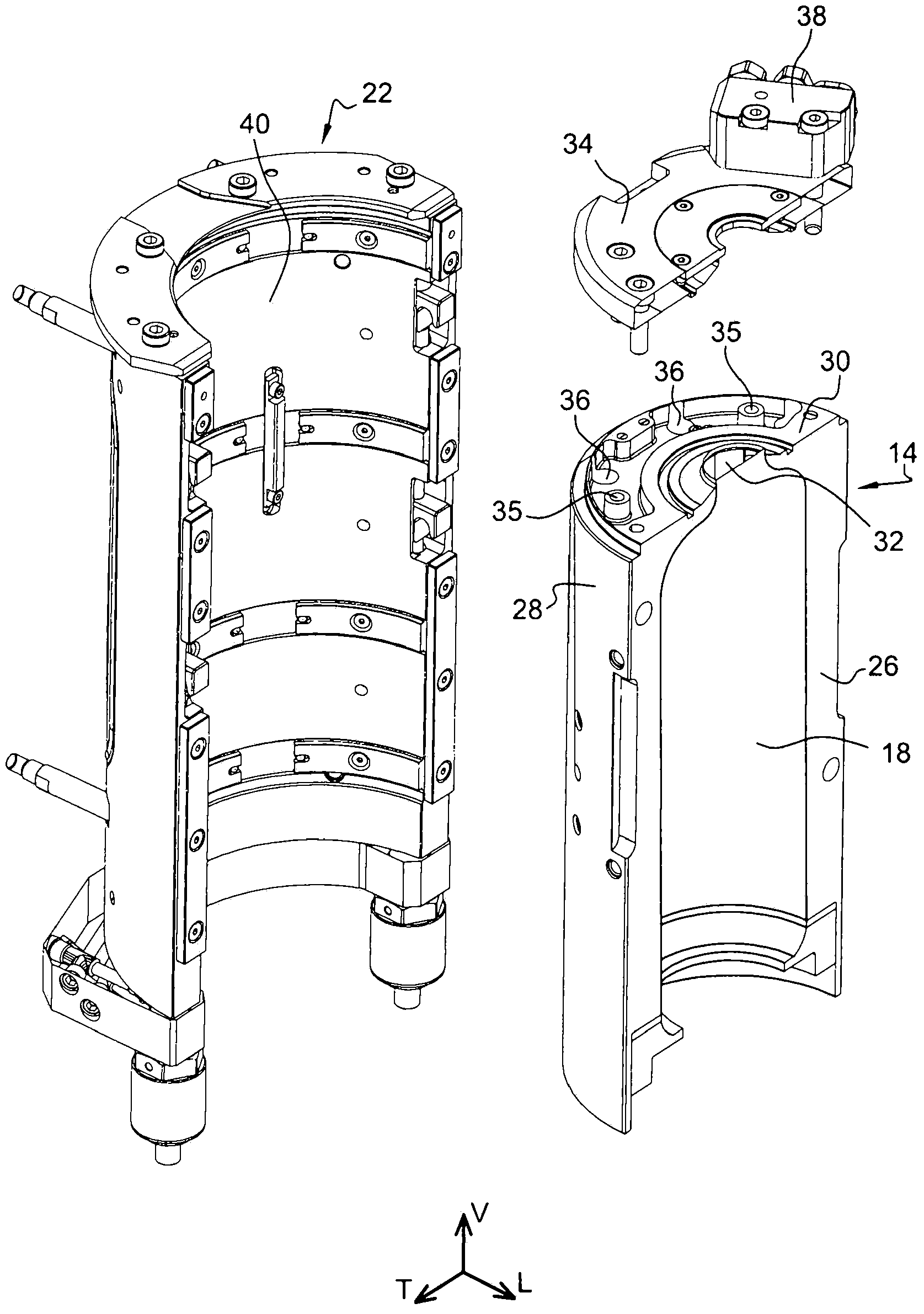

[0039] figure 1 A device 10 for producing containers by blow molding or by stretch blow molding is shown. The device 10 comprises a mold 12 formed by joining two substantially symmetrical mold halves 14, 16 made of metallic material, for example steel or an aluminum alloy.

[0040] The mold 12 thus assembled has the overall shape of a hollow cylinder rotating about a vertical mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com