Flexible packaging process

A flexible packaging and process technology, applied in the directions of printing device, printing, printing plate preparation, etc., can solve the problems of poor leveling of printing microscopic ink layer, white spots of composite aluminized products, and no problems, so as to solve the problem of composite spots and eliminate them. Spotting problems, the effect of reducing ink usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

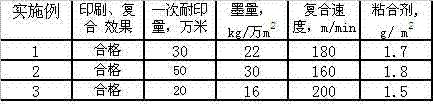

[0013] Embodiment 1 is a preferred embodiment of the present invention. In this embodiment, the printing sample is full plate yellow. When making a plate, the plate making process is determined to be 80 lines / cm, and the engraving knife is 130 degrees. When printing, the yellow plate ink 3# Zaen cup 13 seconds, the printing appearance meets the requirements of the sample, and the composite is made of water-based adhesive or solvent-free composite, and the appearance is excellent. The actual test quality and benefit indicators are shown in Table 1.

Embodiment 2

[0014] Embodiment 2, in the present embodiment, the printing sample draft is full version yellow, when plate making, the plate making process is determined as 80 lines / cm, engraving knife 120 degree engraving knife, during printing, yellow version ink 3# Zaen cup 14 seconds , the printed appearance meets the requirements of the sample, and the water-based adhesive or solvent-free composite is used for lamination and has an excellent appearance. The actual test quality and benefit indicators are shown in Table 1.

Embodiment 3

[0015] Embodiment 3, in the present embodiment, the printing sample draft is a full version of yellow, when plate making, the plate making process is determined to be 80 lines / cm, carving knife 135 degree carving knife, during printing, yellow printing ink 3# Zahn cup 12 seconds , the printed appearance meets the requirements of the sample, and the water-based adhesive or solvent-free composite is used for lamination and has an excellent appearance. The actual test quality and benefit indicators are shown in Table 1.

[0016] After the application of the invention, the product quality can be stably guaranteed, the consumption of ink and composite adhesive can be reduced, the discharge of VOCs can be reduced, and the production efficiency can be improved. The actual test performance is shown in Table 1.

[0017] Table 1

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com