Water-based antiviral negative oxygen ion wood coating and preparation method thereof

A negative oxygen ion, wood coating technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of single function of water-based wood coatings, achieve good resistance effect, reduce the use of organic solvents , the effect of inhibiting bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also discloses a preparation method of water-based anti-virus and negative oxygen ion wood coating, which is characterized in that it comprises the following steps:

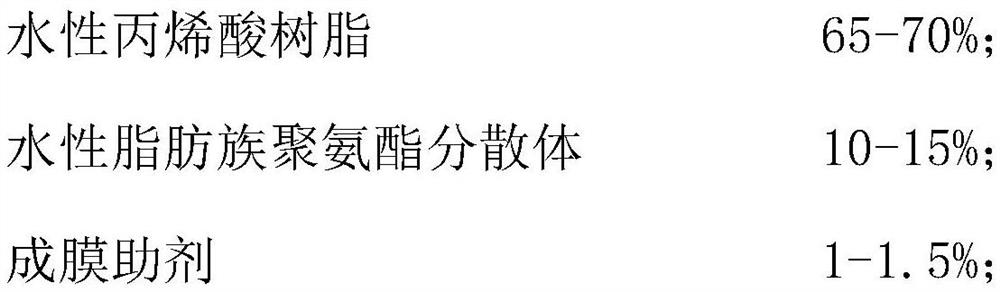

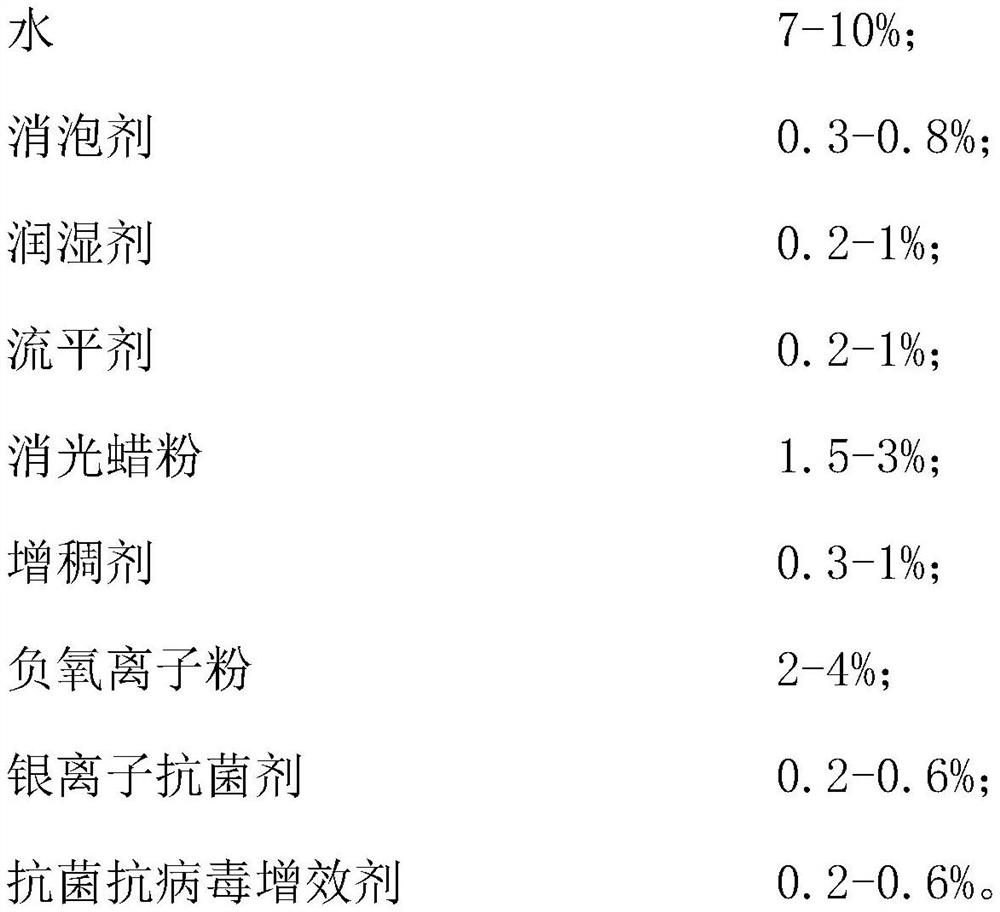

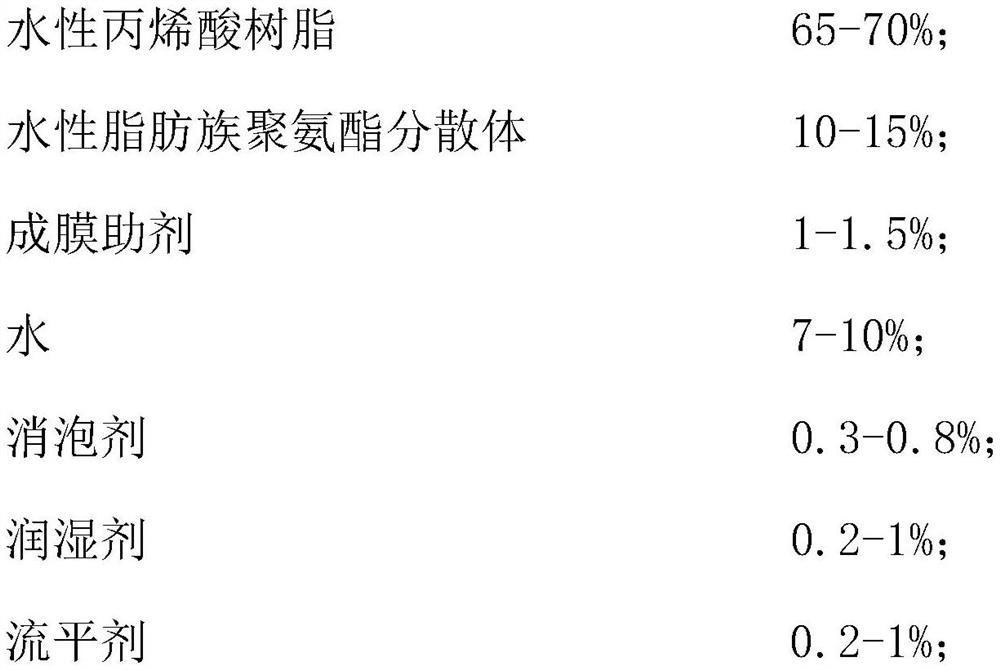

[0041] (1) Prepare raw materials, including the components of the following mass percentage content:

[0042] 65-70% water-based acrylic resin, 10-15% water-based aliphatic polyurethane dispersion, 1-1.5% coalescent, 7-10% water, 0.3-0.8% defoamer, 0.2-1% leveling agent, 0.2-1% wetting agent, 0.3-1% thickener, 1.5-3% matting wax powder, 2-4% negative oxygen ion powder, 0.2-0.6% silver ion antibacterial agent, 0.2-0.6% antibacterial and antiviral synergist;

[0043] (2) Under normal temperature conditions, put water-based acrylic resin and water-based aliphatic polyester dispersion into the high-speed disperser according to the percentage, and put in the mixture of film-forming aids and water, defoamer, and wetting agent at a medium speed. After wetting agent, leveling agent, matting...

Embodiment 1

[0050]

[0051]

[0052] Under normal temperature conditions, put water-based acrylic resin and water-based aliphatic polyester dispersion into the high-speed disperser according to the percentage, and put in the mixture of film-forming aids and water, defoamer, wetting agent, After leveling agent, matting wax powder, thickener, negative oxygen ion powder, silver ion antibacterial agent, antibacterial and antiviral synergist, stir for 20-30 minutes.

Embodiment 2

[0054]

[0055] Under normal temperature conditions, put water-based acrylic resin and water-based aliphatic polyester dispersion into the high-speed disperser according to the percentage, and put in the mixture of film-forming aids and water, defoamer, wetting agent, After leveling agent, matting wax powder, thickener, negative oxygen ion powder, silver ion antibacterial agent, antibacterial and antiviral synergist, stir for 20-30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com