Surface transparent finishing process free of VOCS

A varnishing and crafting technology, which is applied to special surfaces, devices for coating liquids on surfaces, anti-corrosion coatings, etc., can solve problems such as environmental protection and physical hazards, and achieve the effect of reducing environmental and human hazards and reducing VOCs emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

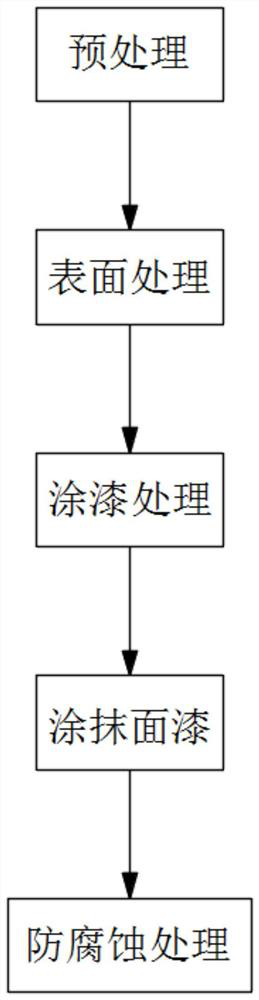

[0018] Step 1, pretreatment: use clean water to remove dust from the steel plate;

[0019] Step 2, surface treatment: using a degreasing agent to remove oil stains on the steel plate, cleaning the steel plate with a water clearing agent, and treating the surface of the steel plate with chromium-free passivation;

[0020] Step 3, painting treatment: apply varnish on the outside of the steel plate, and bake and cure the varnish to form a varnish layer;

[0021] Step 4, apply the top coat: apply the top coat on the varnish;

[0022] Step 5, anti-corrosion treatment: apply a corrosion-resistant material on the inner side of the steel plate, and solidify the corrosion-resistant material to form a corrosion-resistant layer.

[0023] Wherein, the varnish of step three consists of the following parts by weight: leveling agent A 0.48%, butyl acetate 4.5%, polyaspartic acid ester resin 86%, cellulose acetate butyrate 9%, drying 0.02% agent A, 68% isocyanate curing agent and 32% butyl ...

Embodiment 2

[0044] Step 1, pretreatment: use clean water to remove dust from the steel plate;

[0045] Step 2, surface treatment: using a degreasing agent to remove oil stains on the steel plate, cleaning the steel plate with a water clearing agent, and treating the surface of the steel plate with chromium-free passivation;

[0046] Step 3, painting treatment: apply varnish on the outside of the steel plate, and bake and cure the varnish to form a varnish layer;

[0047] Step 4, apply the top coat: apply the top coat on the varnish;

[0048] Step 5, anti-corrosion treatment: apply a corrosion-resistant material on the inner side of the steel plate, and solidify the corrosion-resistant material to form a corrosion-resistant layer.

[0049] Wherein, the varnish of step three consists of the following parts by weight: leveling agent A0.48%, butyl acetate 4.5%, polyaspartic acid ester resin 81%, cellulose acetate butyrate 4%, drying 0.02% agent A, 62% isocyanate curing agent and 38% butyl a...

Embodiment 3

[0066] Step 1, pretreatment: use clean water to remove dust from the steel plate;

[0067] Step 2, surface treatment: using a degreasing agent to remove oil stains on the steel plate, cleaning the steel plate with a water clearing agent, and treating the surface of the steel plate with chromium-free passivation;

[0068] Step 3, painting treatment: apply varnish on the outside of the steel plate, and bake and cure the varnish to form a varnish layer;

[0069] Step 4, apply the top coat: apply the top coat on the varnish;

[0070] Step 5, anti-corrosion treatment: apply a corrosion-resistant material on the inner side of the steel plate, and solidify the corrosion-resistant material to form a corrosion-resistant layer.

[0071] Wherein, the varnish of step three consists of the following parts by weight: leveling agent A0.48%, butyl acetate 4.5%, polyaspartic acid ester resin 81%, cellulose acetate butyrate 4%, drying 0.02% agent A, 68% isocyanate curing agent and 32% butyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com