Low-smoke zero-halogen flame retardant polyolefin cracking resisting material

A technology of polyolefin and flame retardant, applied in the field of material chemistry, to achieve excellent flame retardant properties, good mechanical properties and processing properties, and reduce the effects of environmental and human hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

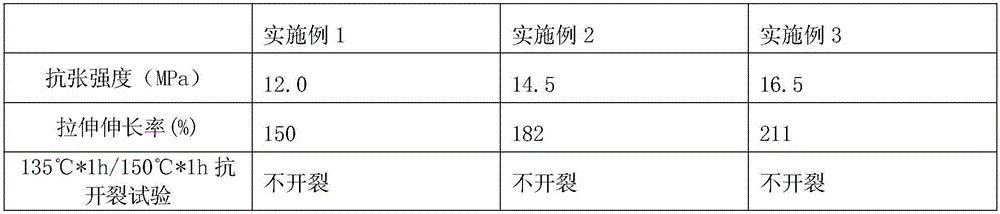

Examples

Embodiment Construction

[0011] The specific implementation of the present invention will be described in further detail below in conjunction with the examples, so as to make the technical solution of the present invention easier to understand and grasp, but the present invention is not limited thereto. The experimental methods described in the following examples, unless otherwise specified, are conventional methods; the reagents and materials, unless otherwise specified, can be obtained from commercial sources.

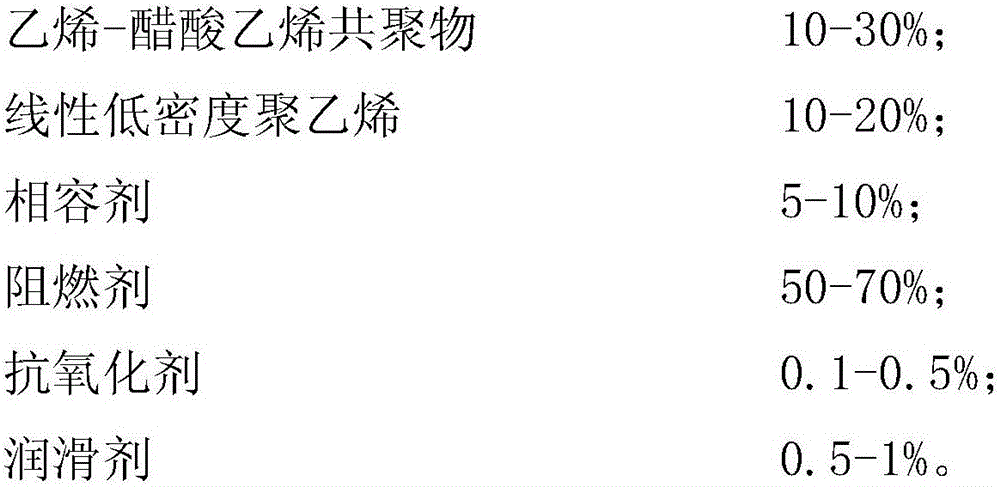

[0012] Embodiments 1-3 prepare low-smoke, halogen-free, flame-retardant polyolefin anti-cracking materials according to the weight percentage of each component in Table 1:

[0013] Table 1

[0014]

Example 1

Example 2

Example 3

Ethylene-vinyl acetate copolymer (EVA)

10%

15%

30%

Linear Low Density Polyethylene (LLDPE)

10%

20%

14%

Compatibilizer

8.5%

10%

5%

Aluminum hydroxide

70%

54%

50%

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com