Conductive silver paste capable of being sintered at low temperature and preparation method therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

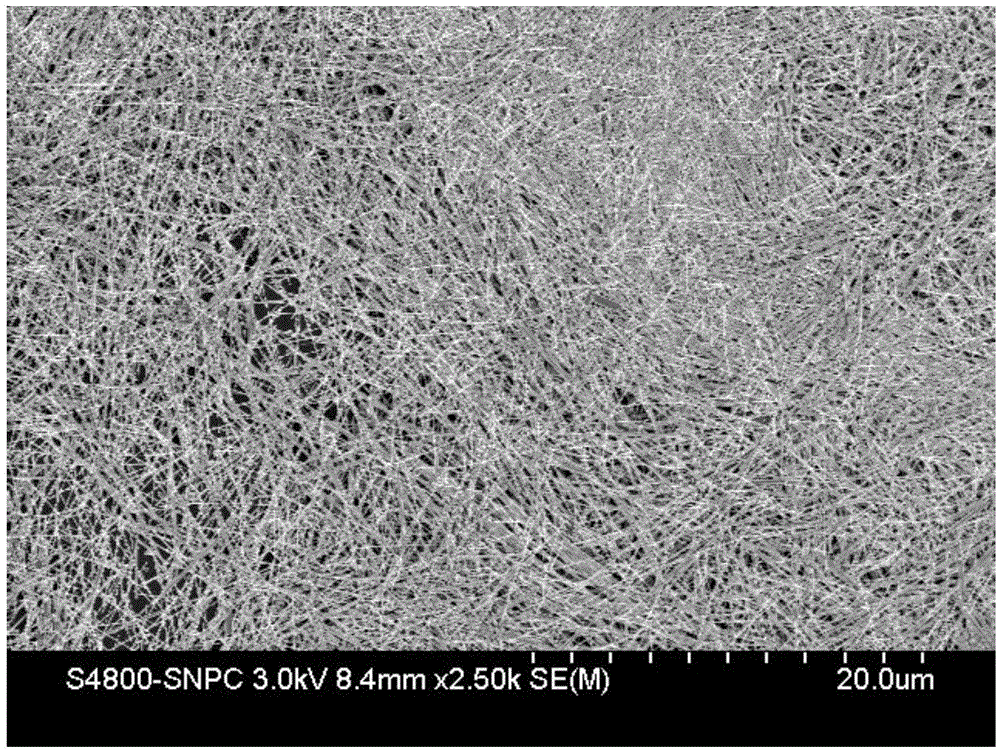

[0042] The preparation steps of nanoscale silver wire among the present invention are as follows:

[0043] Step 1: Mix the silver salt solution with 100ml of ethylene glycol to obtain a mixed solution A with a mass percentage of 5% to 35%;

[0044] Step 2: Mix the protective agent with 100ml of ethylene glycol to obtain a mixed solution B with a mass percentage of 5%~35%;

[0045] Step 3: preparing an inorganic substance ethylene glycol solution with a mass percentage of 0.015% to 1.53% as a control agent;

[0046] Step 4: Take 60ml of ethylene glycol in the lining of 100ml polytetrafluoroethylene, add 0.1~0.5ml of control agent, stir evenly at room temperature, then add mixed solution A and mixed solution B, and continue to stir evenly to obtain mixed solution C;

[0047] Step 5: Put 100ml of polytetrafluoroethylene lining with mixed solution C into the reactor shell, react at 140°C~180°C for 1~3 hours, and cool down with the furnace to obtain the reaction solution;

[004...

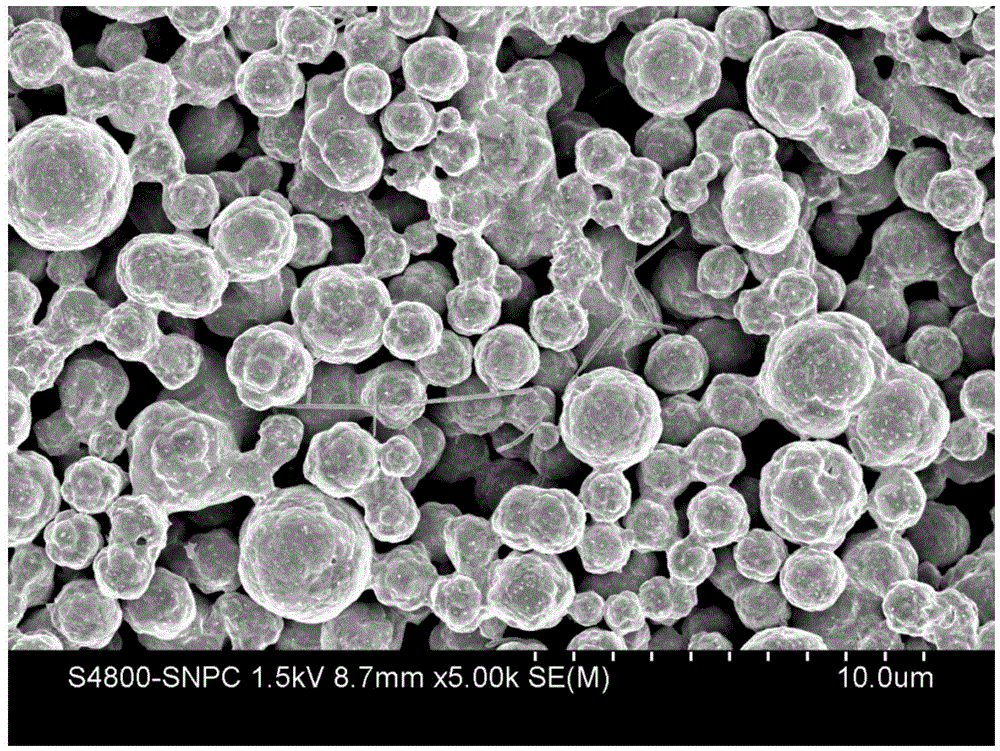

Embodiment 1

[0058] Embodiment 1 adopts micron beaded silver powder to prepare:

[0059] Preparation of nano-scale silver wire:

[0060] Step 1: 10.2g silver nitrate is mixed with 100ml ethylene glycol to obtain a solution A with a mass percentage of 8.39%;

[0061] Step 2: Mix 10.8g polyvinylpyrrolidone with 100ml ethylene glycol to obtain a solution B with a mass percentage of 8.84%;

[0062] Step 3: preparation mass percent is the ethylene glycol solution of the cupric chloride of 0.077%, as control agent;

[0063] Step 4: Take 60ml of ethylene glycol in the lining of 100ml of polytetrafluoroethylene, add 0.1ml of the control agent in step 3, stir evenly at room temperature, then add mixed solution A and mixed solution B, continue to stir evenly , to obtain a mixed solution C;

[0064] Step 5: Put 100ml of polytetrafluoroethylene lining with mixed solution C into the reaction kettle, react at 160°C for 1 hour, and cool with the furnace to obtain the reaction solution;

[0065] Step ...

Embodiment 2

[0074] Embodiment 2 is prepared by adopting micron flake silver powder:

[0075] Preparation of nano-scale silver wire:

[0076] Step 1: 10.2g silver nitrate is mixed with 100ml ethylene glycol to obtain a solution A with a mass percentage of 8.39%;

[0077] Step 2: Mix 10.8g polyvinylpyrrolidone with 100ml ethylene glycol to obtain a solution B with a mass percentage of 8.84%;

[0078] Step 3: preparation mass percentage is the ethylene glycol solution of the sodium chloride of 0.052%, as control agent;

[0079] Step 4: Take 60ml of ethylene glycol in the lining of 100ml of polytetrafluoroethylene, add 0.4ml of the control agent in step 3, stir evenly at room temperature, then add 3ml of solution A and 3ml of solution B, continue Stir evenly to obtain mixed solution C;

[0080] Step 5: Put 100ml of polytetrafluoroethylene lining with mixed solution C into the reaction kettle, react at 160°C for 1 hour, and cool with the furnace to obtain the reaction solution;

[0081] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Solid density | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com