Dot matrix printer and control method thereof

A control method and printer technology, applied to printing devices, printing, etc., can solve the problems of reduced throughput, slower printing speed, longer drive interval, etc., to achieve the effect of suppressing the reduction of throughput and preventing the ink ribbon from being caught

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of a dot matrix printer to which the present invention is applied will be described with reference to the drawings.

[0038] the whole frame

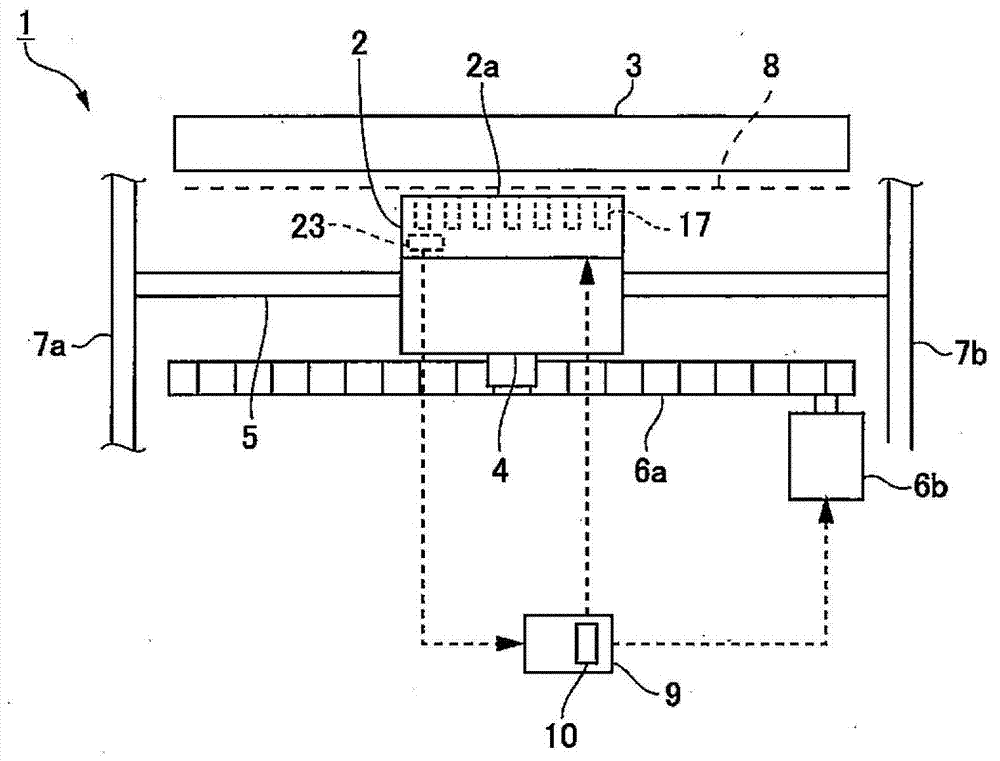

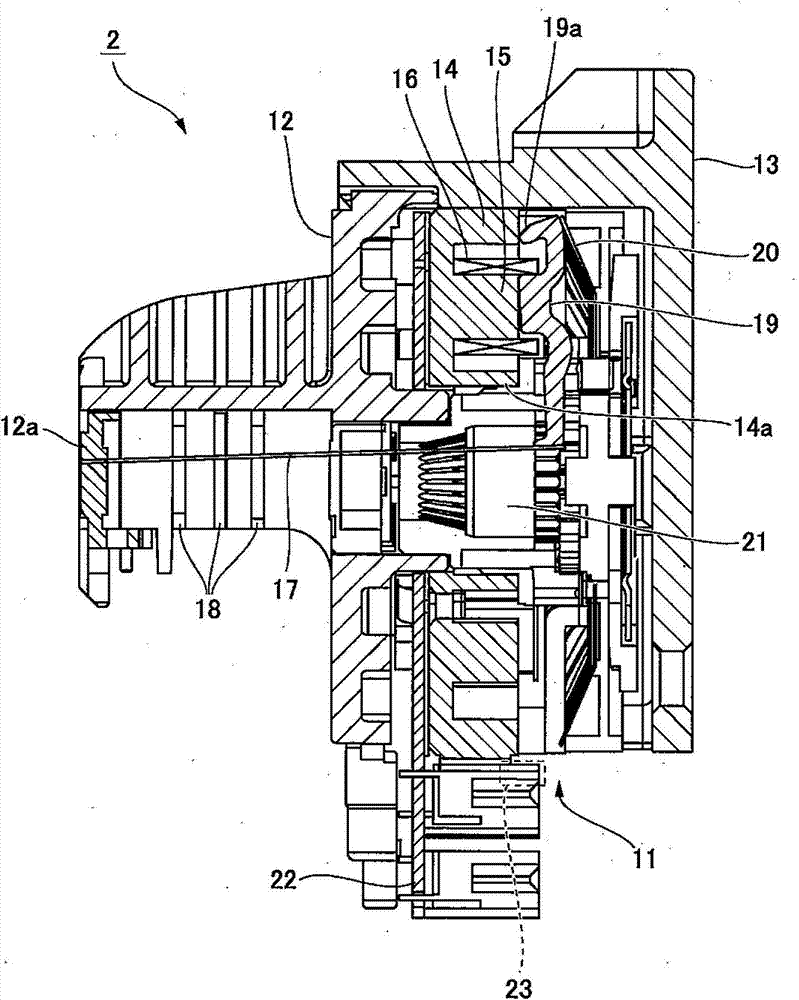

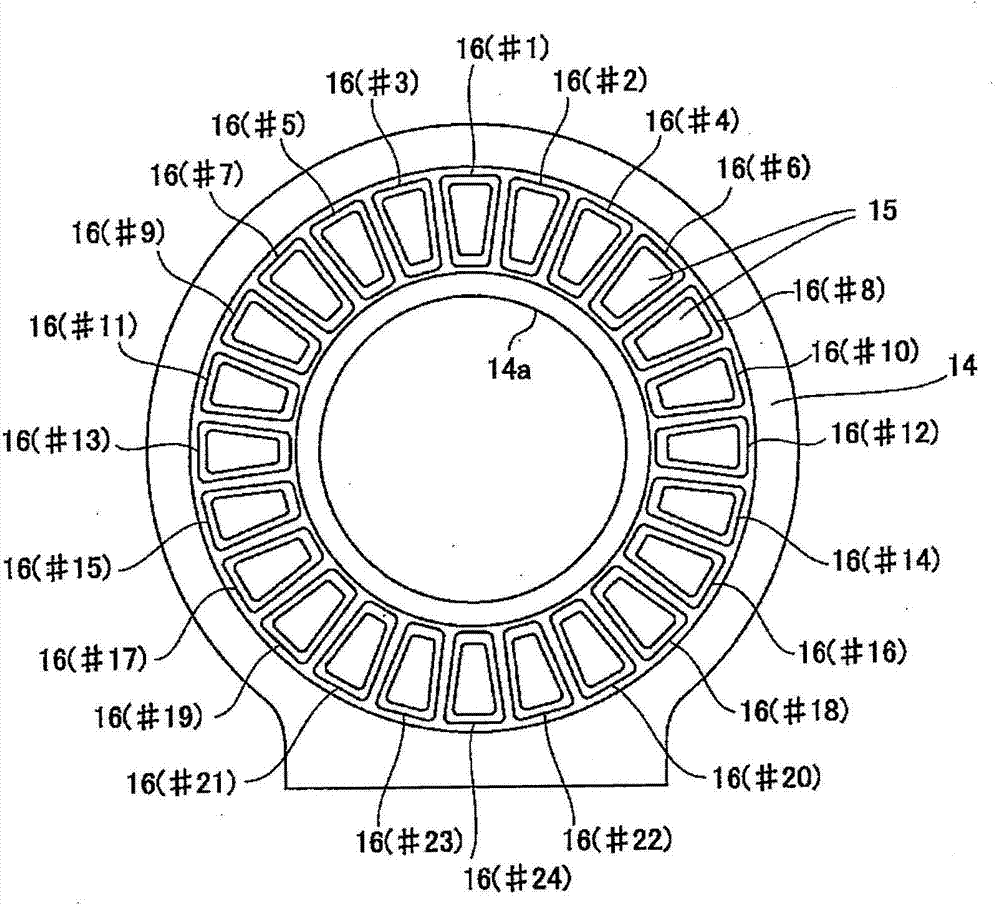

[0039] figure 1 It is a schematic configuration diagram of main parts of the dot matrix printer of this embodiment. The dot matrix printer 1 includes a recording head 2 and a platen 3 arranged to face the recording head 2 with recording paper (recording medium) interposed therebetween. The recording head 2 is mounted on a carriage 4, and the carriage 4 is slidably attached to a carriage guide shaft 5 extending in the printer width direction (paper width direction). The carriage 4 reciprocates in the width direction of the printer based on the output of the carriage motor 6 b via a drive mechanism 6 a such as a timing belt and a pulley. That is, the carriage reciprocates in the head scanning direction. Both ends of the carriage guide shaft 5 are supported by the left and right side plates 7a, 7b of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com