High power wiring structure based on pcb copper foil

A high-power, PCB board technology, used in circuits or fluid pipelines, transportation and packaging, vehicle parts, etc. Reduce the effect of vehicle wiring harness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

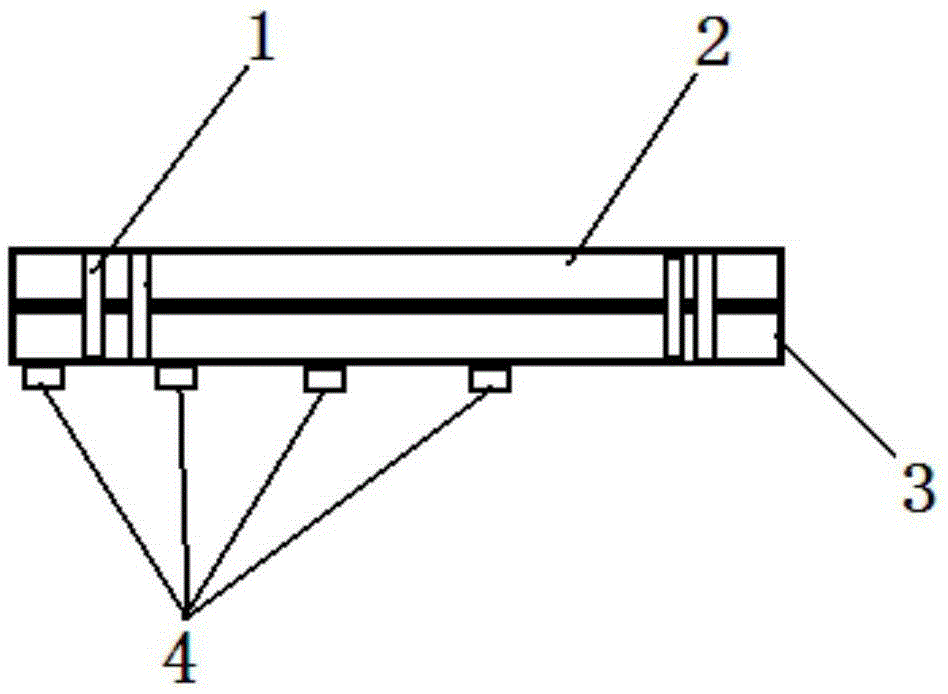

[0020] A high-power wiring structure based on PCB copper foil, including a PCB board, the thickness of the copper foil on the PCB board is 33-36um, preferably 35um; the PCB board includes a first wiring layer 3 and a second wiring layer 2. Both the first wiring layer and the second wiring layer are provided with multiple electronic circuits 4 and wirings connecting multiple electronic circuits; the first wiring layer and the second wiring layer pass through the through hole 1 connect.

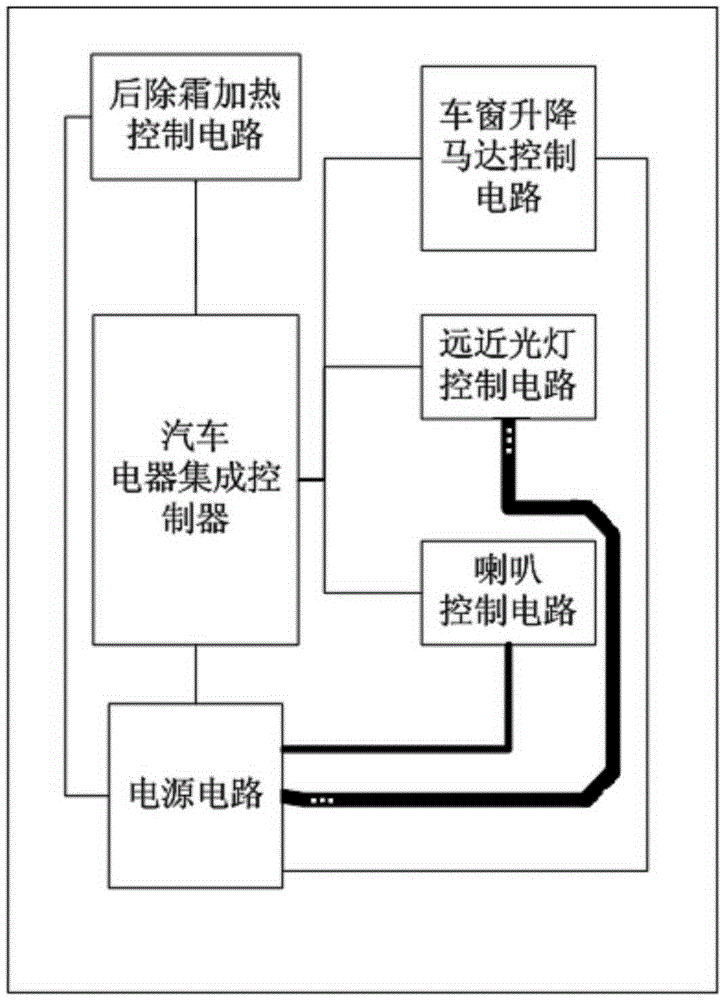

[0021] The electronic circuit includes an integrated controller of automobile electrical appliances, a power supply circuit, a control circuit of high and low beams, a horn control circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com