Wheel loader braking device with double booster pumps

A technology of wheel loader and braking device, applied in the direction of hydraulic braking transmission device, etc., can solve problems such as safety accidents, and achieve the effects of avoiding safety accidents, remarkable effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

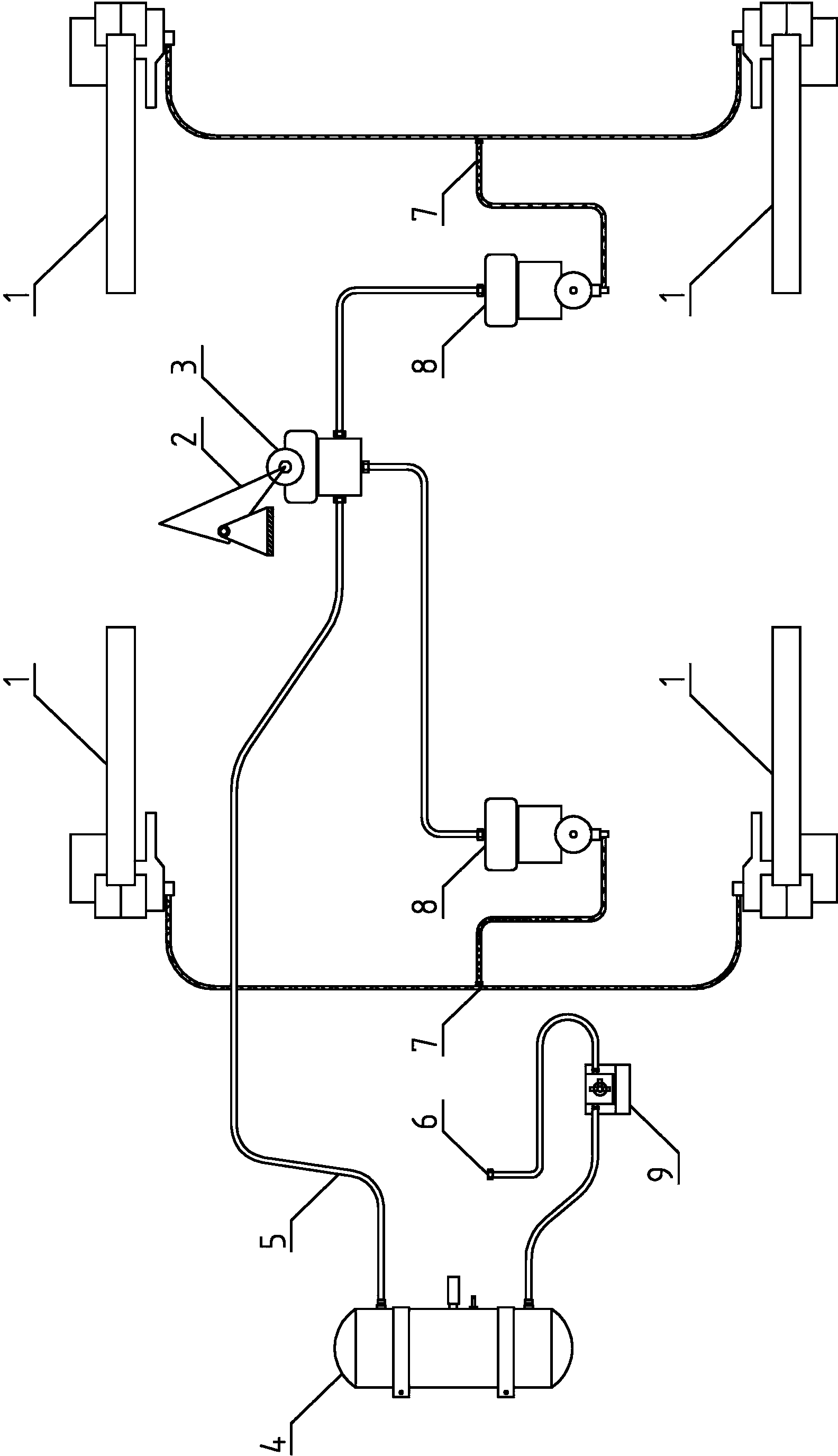

[0008] Embodiment: (see for details figure 1 ) A dual afterburner pump braking device for a wheel loader, which is equipped with an air storage tank 4, a brake assembly 1, a brake air pipe 5 and a brake oil pipe 7, and the two brake air pipes 5 are equipped with one-way valves respectively It is connected with the air storage tank 4, wherein a brake air pipe 5 is sequentially connected with an unloading valve 9 and an air pump interface 6, and the air pump interface 6 is connected with an external engine air pressure pump (not reflected in the figure ), the other brake air pipe 5 is connected with a brake valve 3, the control end of the brake valve 3 is installed with a brake pedal 2, the output end of the brake valve 3 is connected with an afterburner pump 8, and the brake assembly 1 adopts The brake oil pipe 7 is connected to the output end of the afterburner pump 8; in particular: the output end of the brake valve 3 is respectively connected with two afterburner pumps 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com