Corrugated carton

A corrugated box and corrugated paper technology, applied to rigid containers, containers, packaging, etc., can solve the problems of poor compressive performance, high cost, easy to be crushed, etc., and achieve good compressive performance, low production cost, shockproof and cushioning good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

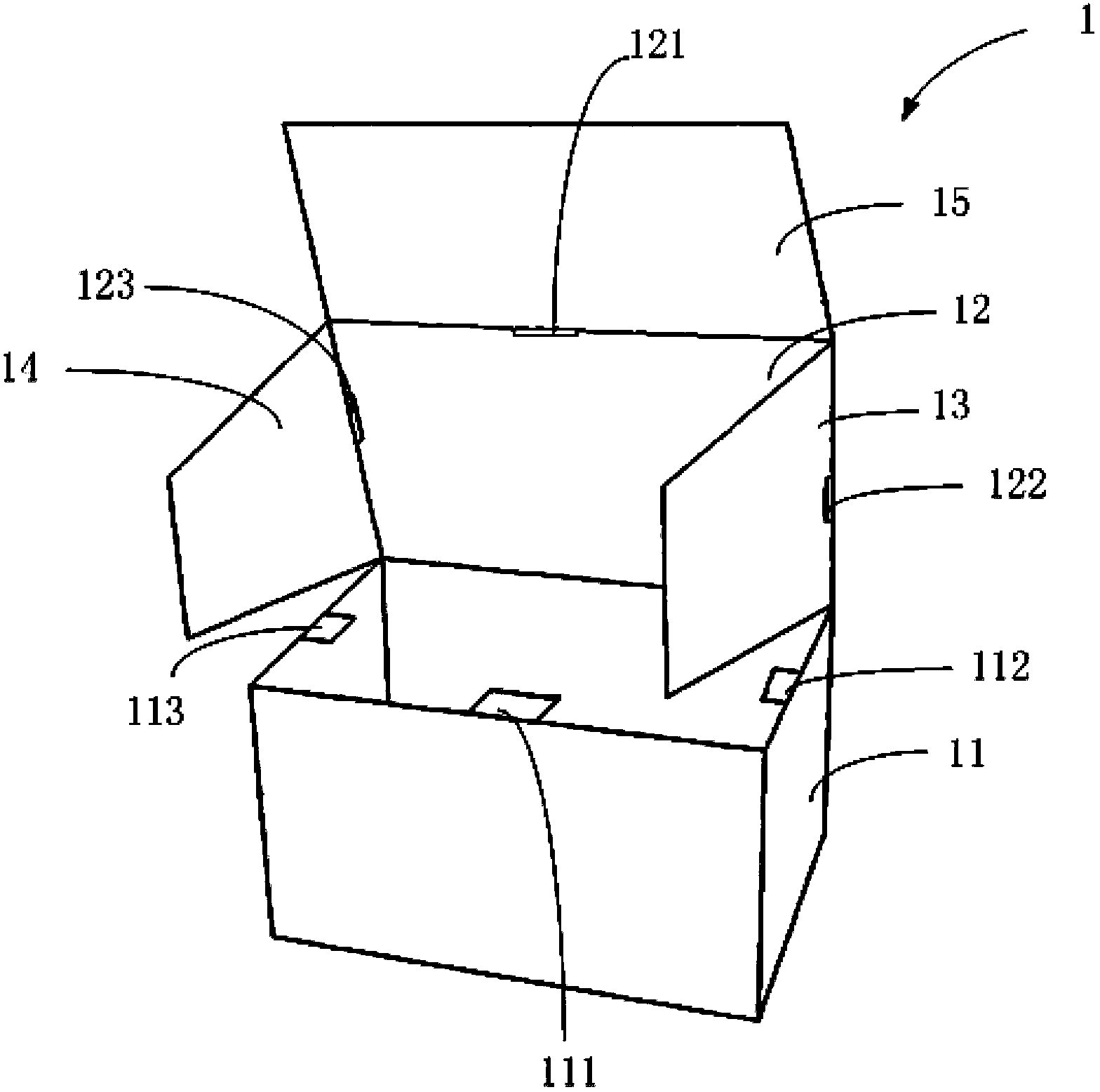

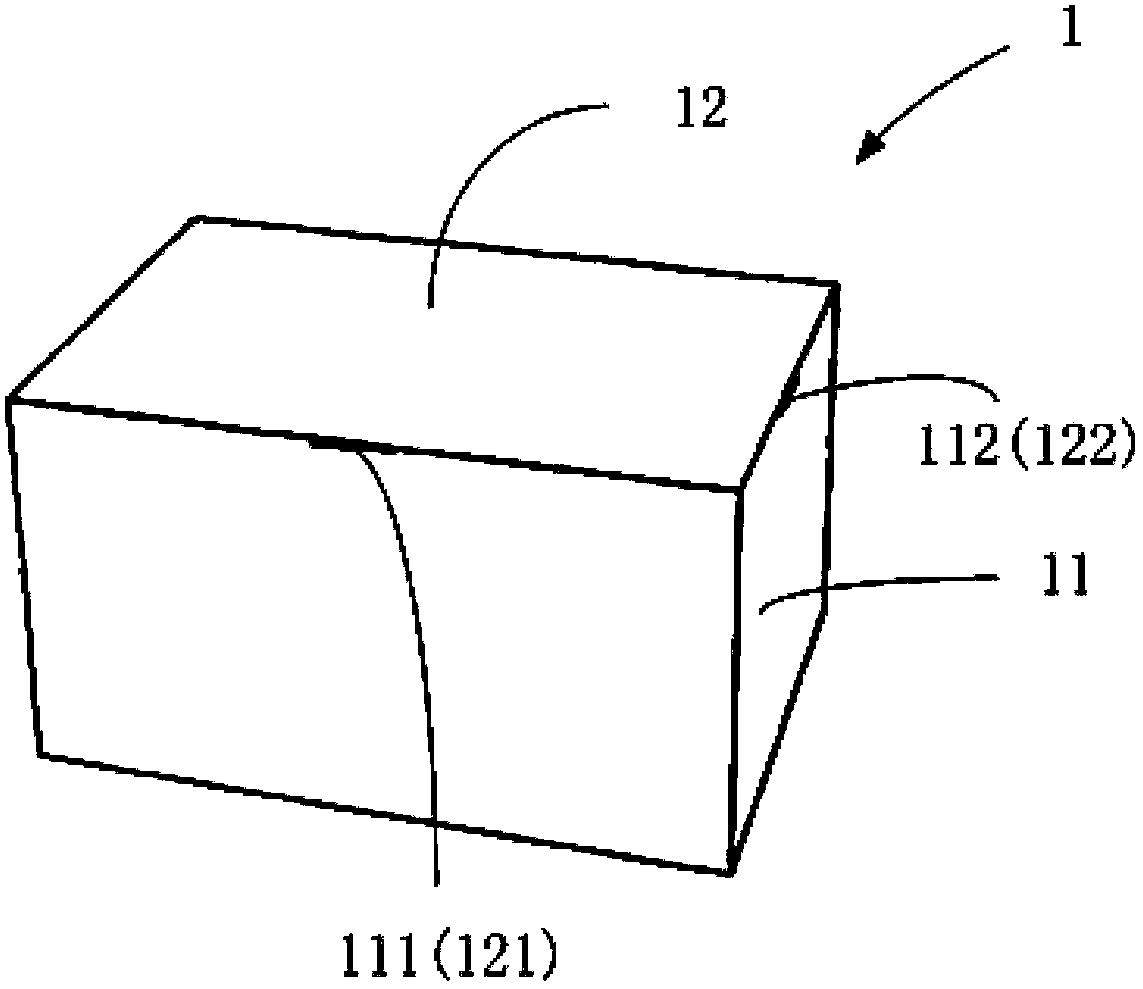

[0013] Please refer to figure 1 , figure 1 It is a schematic diagram when the corrugated box of the embodiment of the present invention is opened. The corrugated cardboard box 1 of this embodiment includes a rectangular hexahedron groove-shaped main box 11 formed by bending corrugated paper. Usually, the main box 11 is a hexahedral structure with one side missing, forming a groove for containing articles. The hexahedral trough structure has the characteristics of regular shape and large capacity.

[0014] The gap surface of the main box body 11 is an upper opening, and one of the four edges of the upper opening of the main box body 11 is connected with a box cover 12 . The box cover 12 is a rectangle matching the opening, and the box cover 12 is used to cover the main box body 11 to form a complete rectangular hexahedron structure. In addition to an edge connected with the case cover 12, the opening on the main body case also has three edges. In this embodiment, as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com