Organic garbage compost reactor

A technology of composting reactor and organic waste, which is applied in the direction of preparation and application of organic fertilizers and organic fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

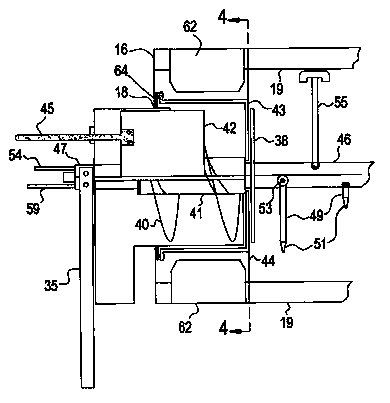

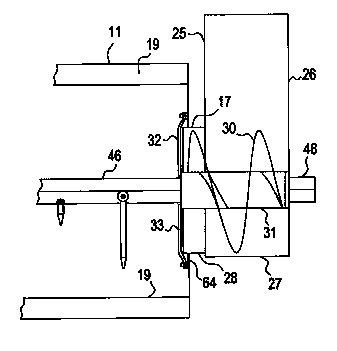

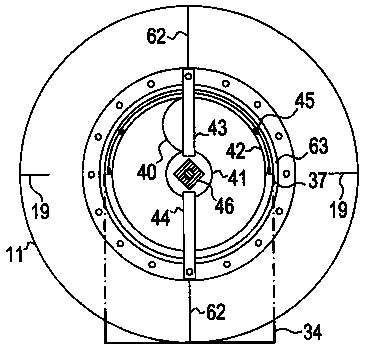

[0013] figure 1 As shown, the composting reactor of the present invention includes a cylindrical steel container or tank supported by at least two rollers 12 , 13 , and the rollers are installed on a base 14 . A servo motor 20 is connected with the container, and drives the container to rotate through the roller. The two ends of the container 11 are welded with circular plates 15,16, and the middle part of the circular plate has larger circular openings 17,18. Multiple rows of vanes 19 are arranged on the inner wall of the container along the length direction of the container. a feeding chute 21, figure 1 and image 3 As shown, it is mounted on the base 14 by the upright 22, and the slot 21 is adjacent to the end 15 of the container. Feed chute 21 consists of a side and end topped with a waste inlet. side ( figure 1 , image 3 The part between middle 25 and 26) extends vertically downward and is sealingly connected with the semi-cylindrical shell 27, which constitutes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com