Small kitchen garbage on-site fertilization equipment

A technology of kitchen waste and chemical equipment, which is applied in the field of organic waste recycling, can solve the problems of increasing the treatment load of urban sewage treatment plants, difficulty in market promotion and application, and low quality organic fertilizer products, so as to shorten the composting cycle and improve The effect of fertilizer humus content and detonation time shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

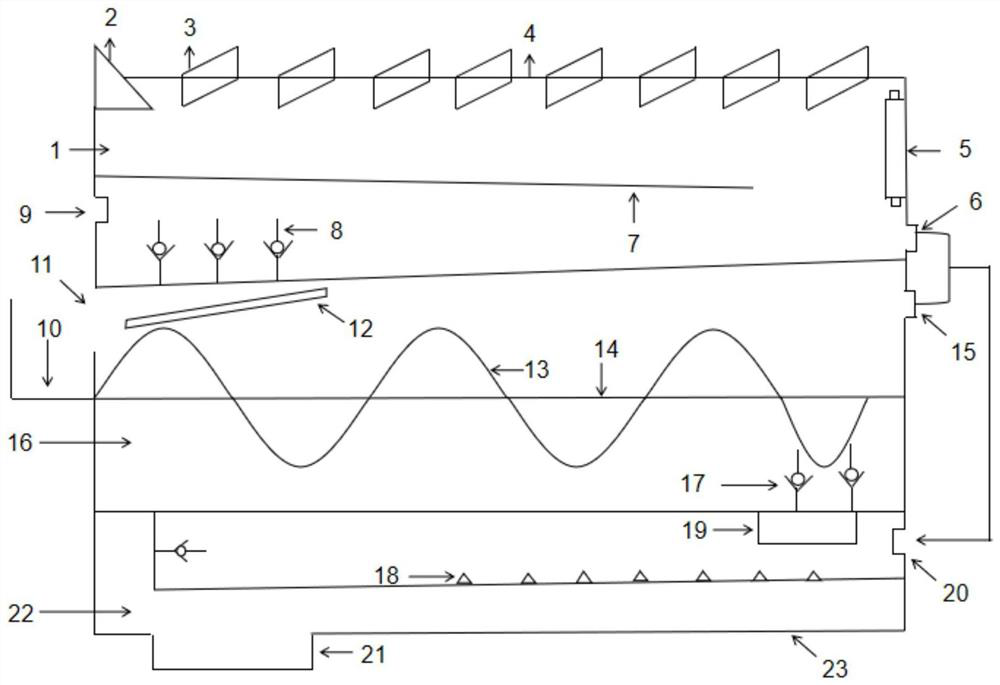

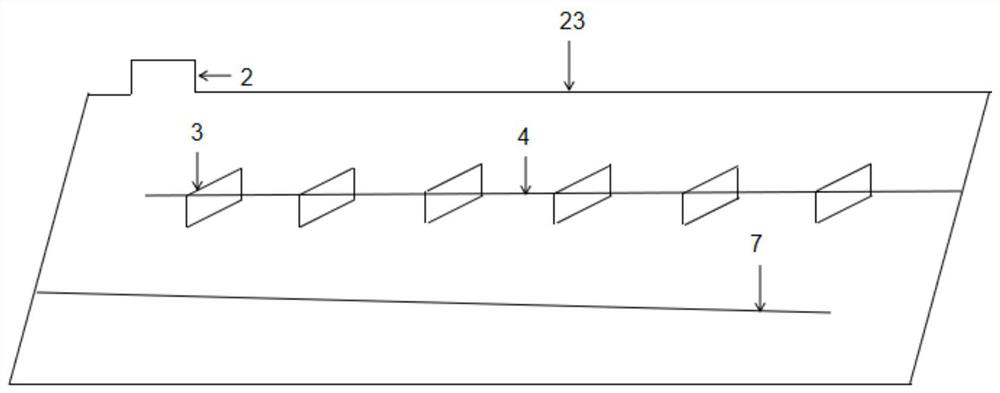

[0029] The small-scale kitchen waste in-situ fertilization equipment proposed by the present invention adopts a vertical and three-stage design, and combines vertical gravity sedimentation one-way feeding with horizontal spiral propulsion feeding, effectively reducing the floor space and shortening the composting cycle , and through staged aerobic fermentation, the energy consumption of different stages is compensated, and the fermentation microenvironment is optimized, which not only saves energy consumption in operation, but also improves the quality of fertilizer and realizes the rapid fertilization of kitchen waste.

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the directions such as up, down, left, and right mentioned in this specification are all based on the directions shown in the drawings.

[0031] The equipment of the present invention is a vertical and three-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com