Organic fertilizer produced by using sugarcane filter mud and municipal sludge and preparation method of organic fertilizer

A technology for municipal sludge and sugarcane filter mud, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts. It can solve problems such as environmental pollution, reduce costs, promote the formation of humus, and reduce nitrogen volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

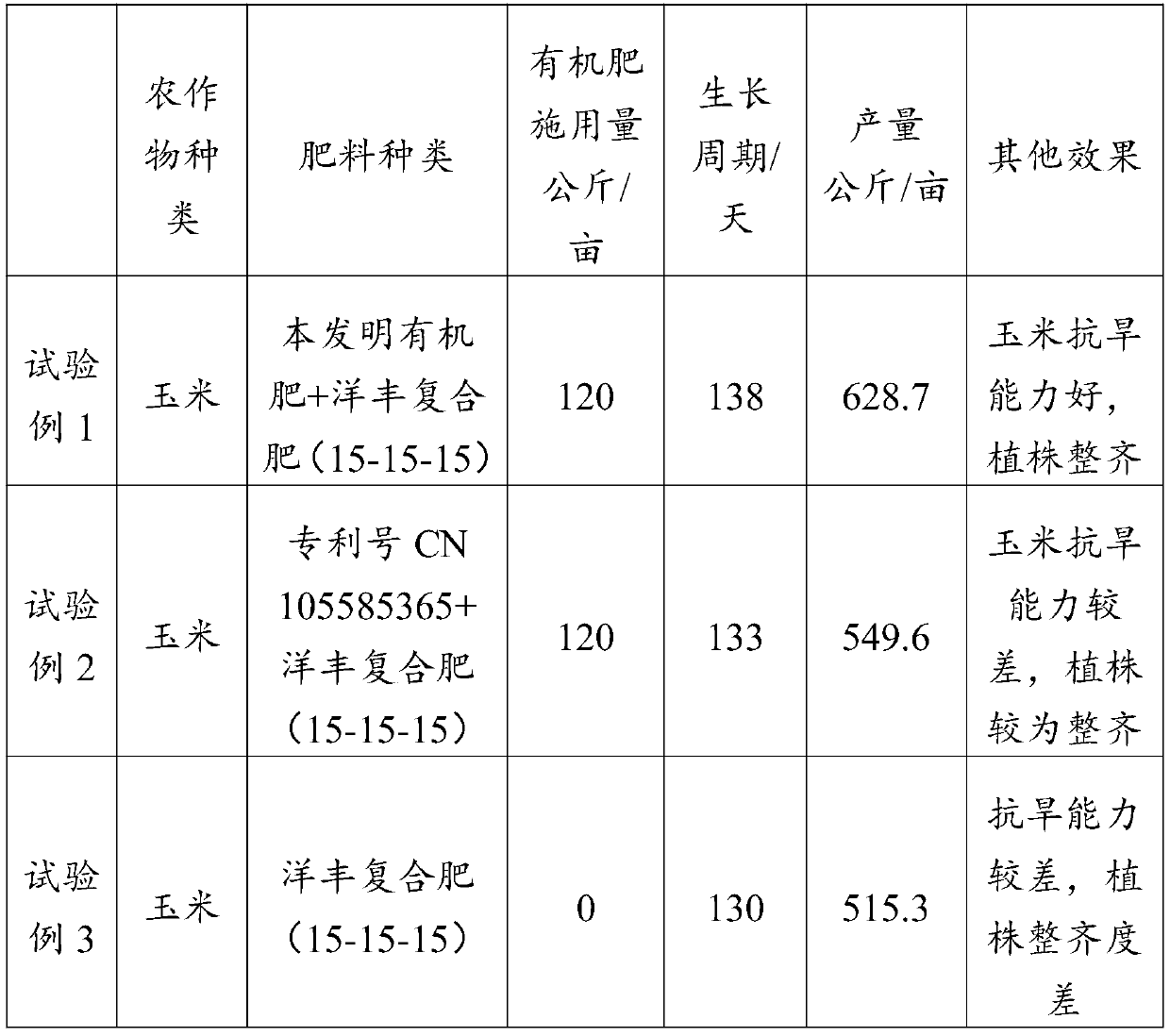

Embodiment 1

[0034] An organic fertilizer produced from sugarcane filter mud and municipal sludge, comprising the following raw materials in parts by weight: 90 parts of sugarcane filter mud, 80 parts of municipal sludge, 30 parts of straw, 13 parts of rapeseed, 20 parts of cassava residue 19 parts of molasses, 7 parts of fish meal, 0.3 part of decomposing bacteria agent, 0.2 part of heavy metal passivator A, 0.4 part of heavy metal passivator B, 0.5 part of nitrogen-fixing bacterial fertilizer.

[0035] Above the preparation method of the organic fertilizer produced with sugarcane filter mud and municipal sludge may further comprise the steps:

[0036] (1) Straw pretreatment: crush the straw to a particle size of 2 cm, and naturally dry it until the mass fraction of moisture is 20%; wherein the straw is cassava stalk;

[0037] (2) Rapeseed dry pretreatment: crush the rapeseed dry to 10 meshes with a crusher;

[0038] (3) 3 parts of molasses, 2 parts of fishmeal, decomposed bacteria agent...

Embodiment 2

[0043] An organic fertilizer produced from sugarcane filter mud and municipal sludge, comprising the following raw materials in parts by weight: 100 parts of sugarcane filter mud, 90 parts of municipal sludge, 35 parts of straw, 17 parts of rapeseed, 25 parts of cassava residue 23 parts of molasses, 13 parts of fish meal, 0.4 part of decomposing bacteria agent, 0.3 part of heavy metal passivator A, 0.5 part of heavy metal passivator B, 1.0 part of nitrogen-fixing bacterial fertilizer.

[0044] Above the preparation method of the organic fertilizer produced with sugarcane filter mud and municipal sludge may further comprise the steps:

[0045] (1) Straw pretreatment: crush the straw to a particle size of 3 cm, and naturally dry it until the mass fraction of moisture is 30%; wherein the straw is cassava stalk and mulberry branch;

[0046] (2) Rapeseed dry pretreatment: crush the rapeseed dry to 16 meshes with a crusher;

[0047] (3) 3 parts of molasses, 2 parts of fishmeal, dec...

Embodiment 3

[0052] An organic fertilizer produced from sugarcane filter mud and municipal sludge, comprising the following raw materials in parts by weight: 110 parts of sugarcane filter mud, 100 parts of municipal sludge, 40 parts of straw, 27 parts of rapeseed, 30 parts of cassava residue 26 parts of molasses, 17 parts of fish meal, 0.5 part of decomposing bacteria agent, 0.5 part of heavy metal deactivator A, 0.7 part of heavy metal deactivator B, and 1.2 parts of nitrogen-fixing bacterial fertilizer.

[0053] Above the preparation method of the organic fertilizer produced with sugarcane filter mud and municipal sludge may further comprise the steps:

[0054] (1) Straw pretreatment: crush the straw to a particle size of 5 cm, and dry it naturally until the mass fraction of water is 35%; wherein the straw is cassava stalks, mulberry branches and tobacco stalks;

[0055] (2) Rapeseed dry pretreatment: crush the rapeseed dry to 18 meshes with a crusher;

[0056] (3) 3 parts of molasses, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com