Method for preparing acipimox

A technology of sodium tungstate and hydrogen peroxide is applied in the field of preparation of acilimus to achieve the effects of improving blood lipid content, convenient operation and reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of A method for preparing acipimox, the method comprising the following steps:

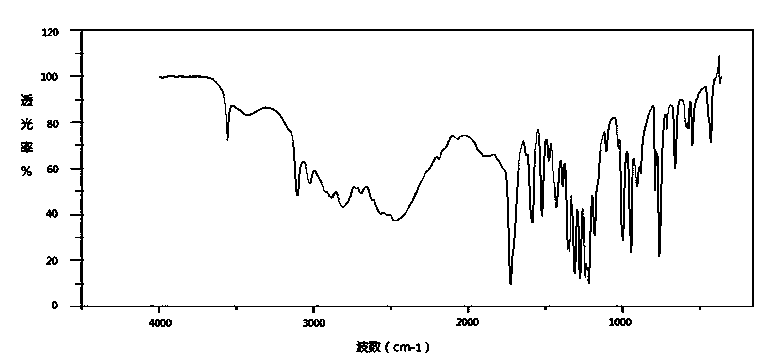

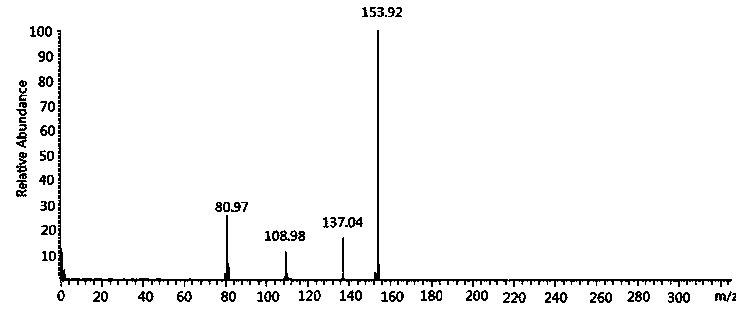

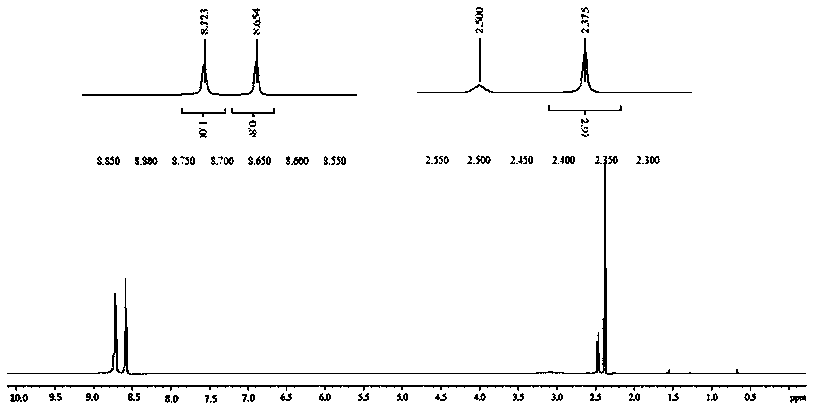

[0031] Add 2730ml of concentrated sulfuric acid with a mass concentration of 98% into a 10L glass reactor, add 910.0g of 5-methylpyrazine-2,3-dicarboxylic acid under stirring conditions, heat to 60°C, heat the reaction for 1h, then slowly Add 5.5kg of water, 164.9g of sodium tungstate (Na 2 WO 4 2H 2 O), 623.0g of hydrogen peroxide with a mass concentration of 30%, continued heating and stirring for 8h, cooled and crystallized in an ice bath for 4h, filtered the solid with suction, dried at 100°C for 12h, and prepared 708.0g of the product acipimox. The product yield in this reaction was 92%; the HPLC purity was greater than 99% (area normalization method).

Embodiment 2

[0032] Example 2: A method for preparing acipimox, the method comprising the following steps:

[0033] Add 5.5kg of water into a 10L glass reactor, slowly add 27ml of concentrated sulfuric acid with a mass concentration of 98% under stirring conditions, then add 910.0g of 5-methylpyrazine-2,3-dicarboxylic acid, and heat the reaction at 60°C 1h, then add 164.9g sodium tungstate (Na 2 WO 4 2H 2 O), 623.0g of hydrogen peroxide with a mass concentration of 30%, continued heating and stirring for 8h, cooled and crystallized in an ice bath for 4h, filtered the solid with suction, dried at 100°C for 12h, and prepared 693.5g of the product acipimox. The product yield in this reaction is 90%; the HPLC purity is greater than 99% (area normalization method).

Embodiment 3

[0034] Example 3: A method for preparing acipimox, the method comprising the following steps:

[0035] Add 2000ml of concentrated hydrochloric acid with a mass concentration of 36% into a 10L glass reactor, then add 910.0g of 5-methylpyrazine-2,3-dicarboxylic acid, heat at 70°C for 1.5h, then slowly add 5.5kg of water , and then add 82.5g sodium tungstate (Na 2 WO 4 2H 2 O), 680.0g of hydrogen peroxide with a mass concentration of 30%, continued heating and stirring for 10h, cooled and crystallized in an ice bath for 4h, filtered the solid with suction, dried at 100°C for 12h, and prepared 678.1g of the product acipimox. The product yield in this reaction was 88%; the HPLC purity was greater than 98% (area normalization method).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com