Dustproof device of swinging rod of plastic circular weaving machine

A technology of dust-proof device and machine swing rod, which is applied in looms, textiles, textiles and papermaking, etc., can solve problems such as excessive dust, bearing failure, bearing seizure, etc., to reduce operation and maintenance costs, prolong service life, and improve quality Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

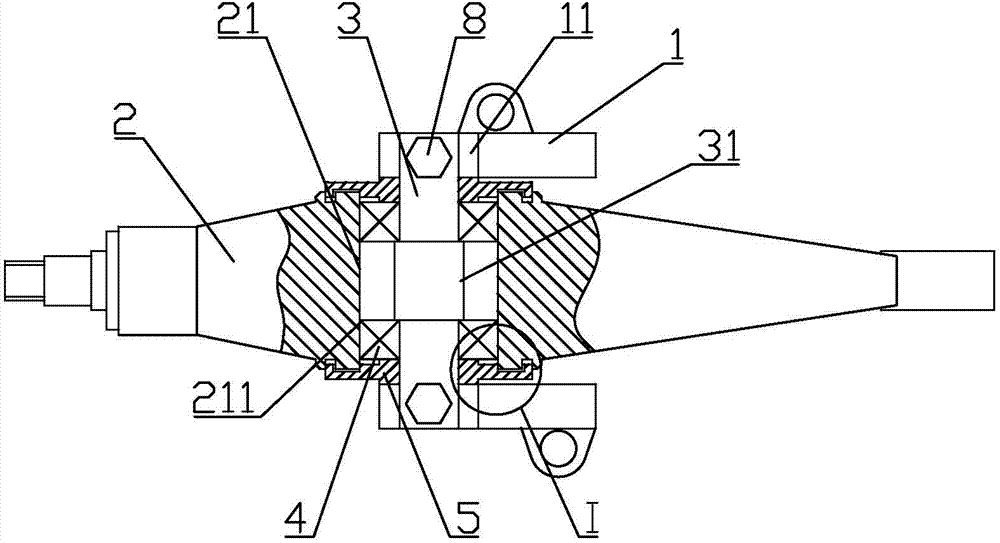

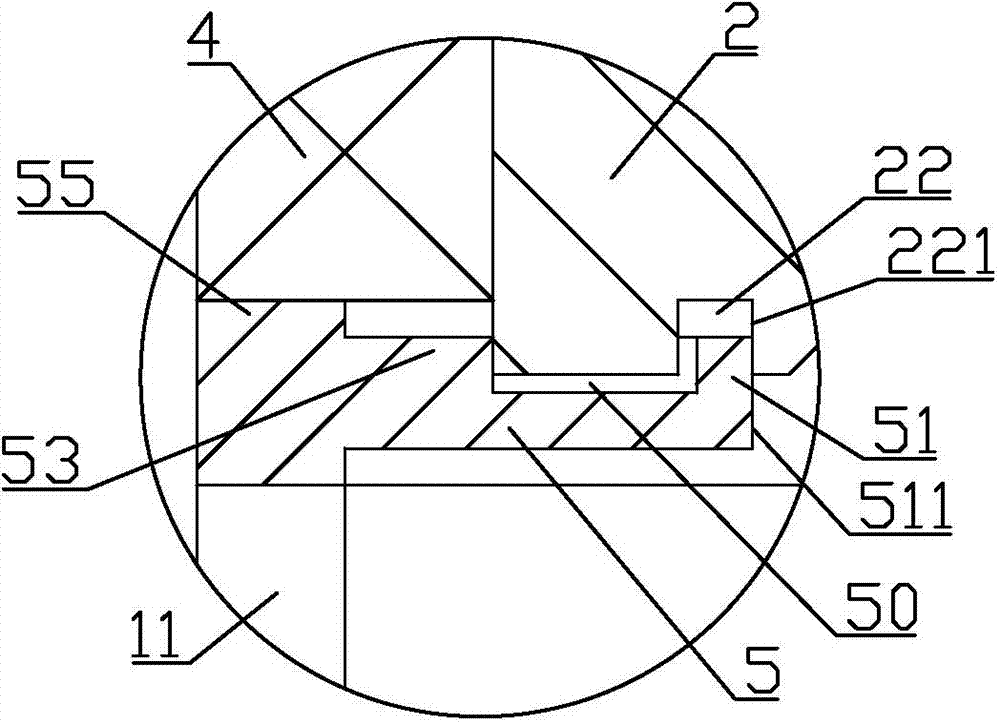

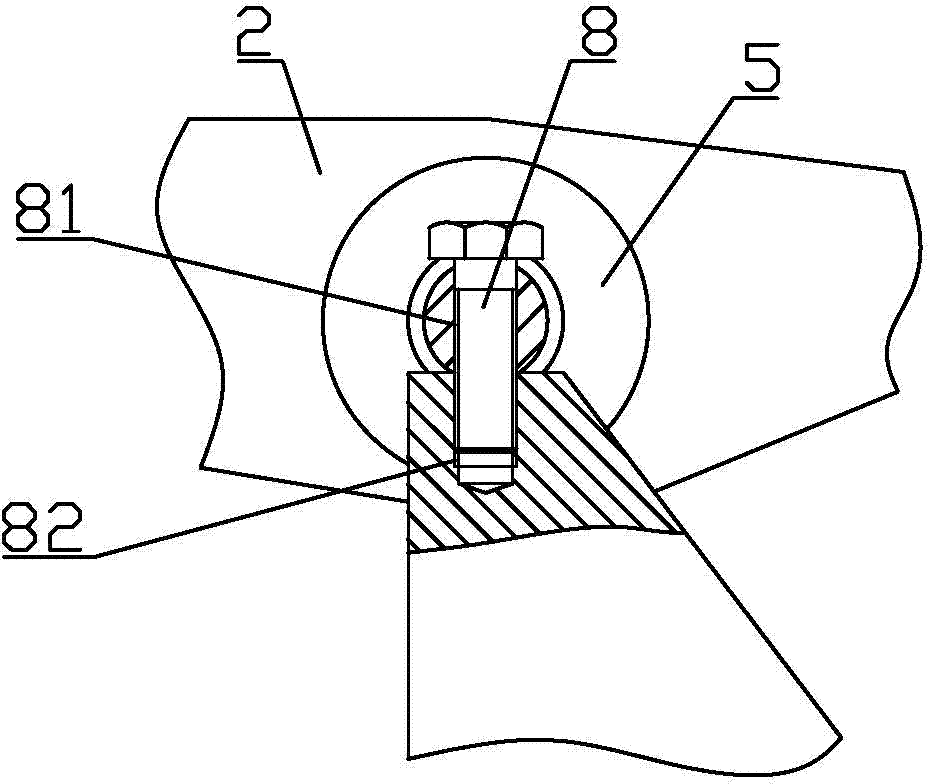

[0044] Such as figure 1 and 2One embodiment of the invention is shown. A dust-proof device for a swing rod of a plastic circular loom, comprising a support 1, a swing rod 2 and a mandrel 3, the support 1 is located on both sides of the swing rod 2 and is provided with support parts 11, and the swing rod 2 is provided with mounting holes 21. The mandrel 3 is set in the installation hole 21 and the two ends of the mandrel 3 protrude from the installation hole 21 to connect with the support part 11 of the support 1. The bearing 4 assembled with the mandrel 3 is arranged in the installation hole 21, and the installation hole The two ends of 21 are provided with dust-proof cover 5, and dust-proof cover 5 is enclosed within on the mandrel 3, requires sealing between dust-proof cover 5 and mandrel 3, because mandrel 3 and dust-proof cover 5 are both when fork 2 swings. Can not rotate, so this point of sealing between the dust cover 5 and the mandrel 3 can be well guaranteed, so dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com