Fabric with clasps, knitting machine for weaving the fabric, and weaving method

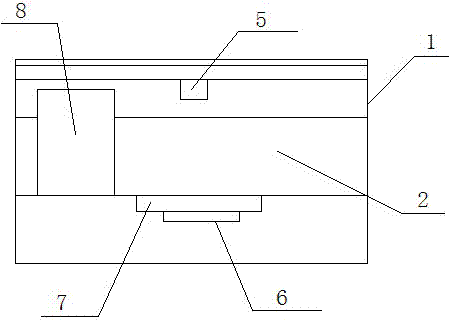

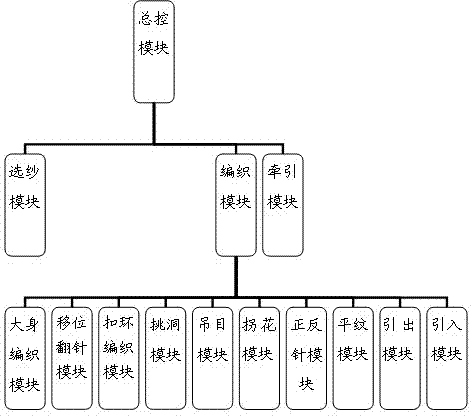

A knitting machine and buckle technology, applied in the field of fabrics, can solve the problems of different sizes of buckles, increase in production cost, decrease in product quality, etc., and achieve the effects of reducing production cost, improving work efficiency, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0066] The rest are the same as in Example 1, except that the body is knit on the front and rear needle beds respectively, and the buckle is divided into two times on the front and back needle beds to start adding needles, which saves the transfer action of the knitting loop of the buckle, Reduce procedures and improve work efficiency.

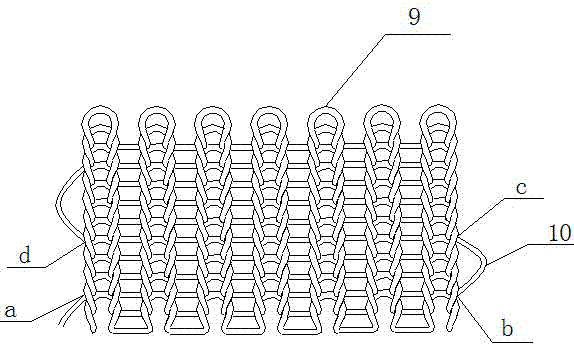

[0067] The invention discloses a fabric with a buckle, which includes a body and a buckle arranged in the needle row direction of the body. Weave 1 mesh on the body, and knit the body and buckle together. By weaving the yarn at the beginning of the buckle to the body, the beginning of the buckle is effectively connected to the body, and by introducing the yarn at the end of the buckle into the body and weaving a mesh, so that the end of the buckle is connected to the body Connected to each other, weaving the buckle while the body is weaving, realizing the integrated weaving of the body and the buckle, saving corresponding multiple processes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com