A construction method for the main tower of a cable-stayed bridge with a single curved tower and double cable planes

A construction method and double-cable surface technology, which is applied to bridges, bridge materials, bridge construction, etc., can solve the problems of high cost of formwork supports and stiff skeletons, installation accuracy of pre-buried sections of steel arch towers, and construction safety risks that are difficult to control. , to achieve the effect of shortening construction time, reducing multiple processes, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing.

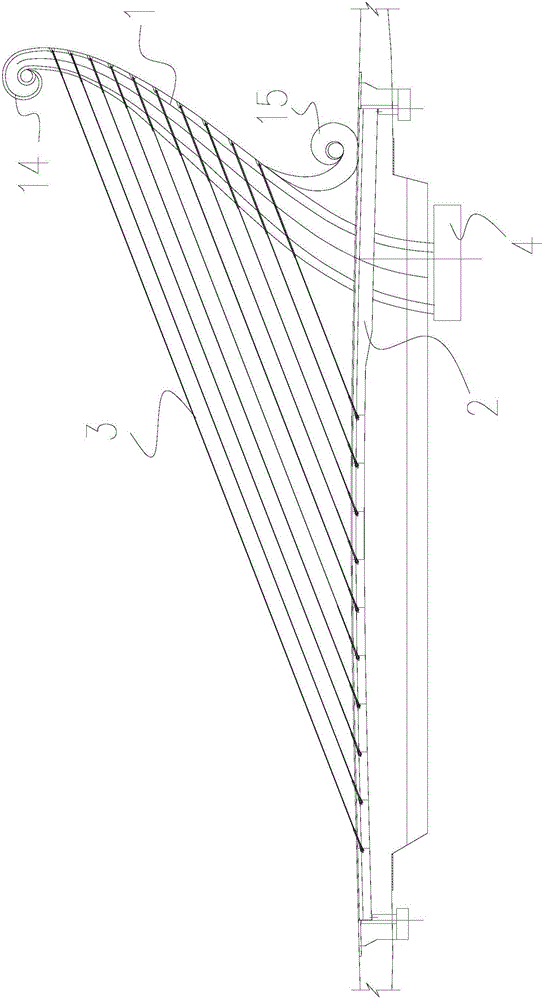

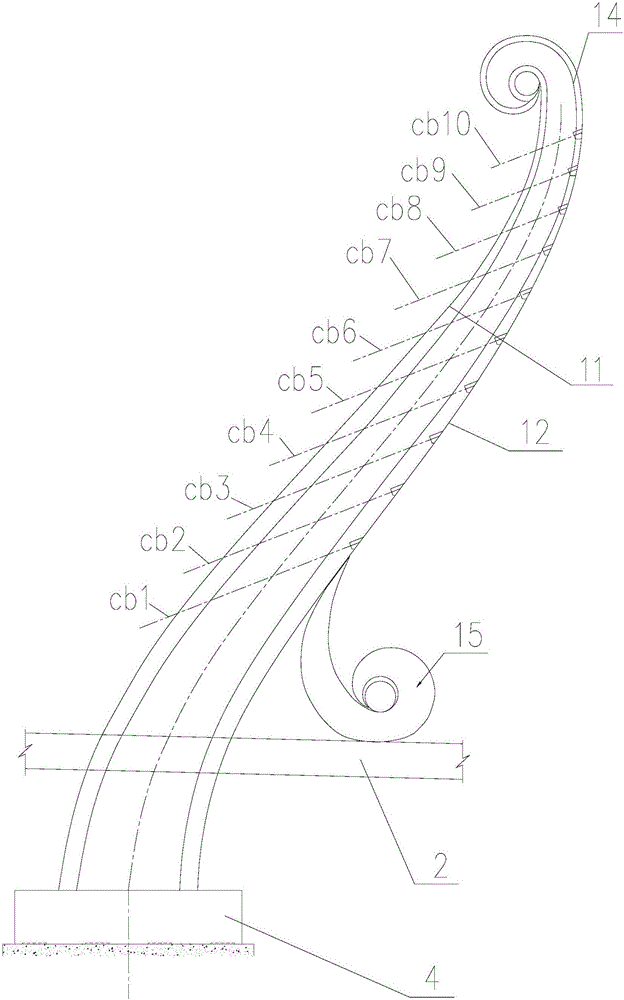

[0051] see Figure 1 to Figure 3 , the cable-stayed bridge with curved single tower and double cable plane includes main tower 1, main girder 2, stay cables 3 and cap 4.

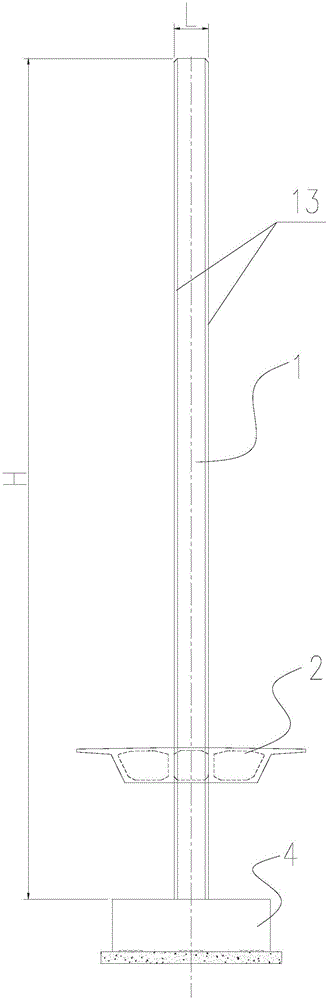

[0052] The main tower 1 is a reinforced concrete structure and a solid cross-section with four sides chamfered. The longitudinal inclination angle of the back cable surface 12 is different and changes segment by section with the construction of the main tower. The longitudinal inclination angles of the rope-guiding surface 11 and the rope-backing surface 12 at the bottom and top of the tower are close to 90°; the two sides 13 of the main tower 1 are plane and the width gradually decreases linearly from bottom to top, so that the height of the main tower 1 The direction from the bottom of the tower to the top of the tower gradually reduces the cross section, and makes the main tower 1 look like an S-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com