Ink screen printing process for thick copper white solder resist ink pcb board

A technology of solder resist ink and PCB board, which is applied in the direction of printed circuit, printed circuit manufacturing, and secondary treatment of printed circuit, etc. The effects of white oil cracks, shortening the standing time, and reducing the cost of silk screen printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

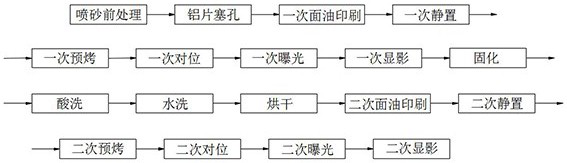

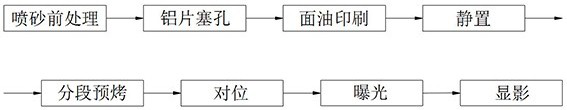

Method used

Image

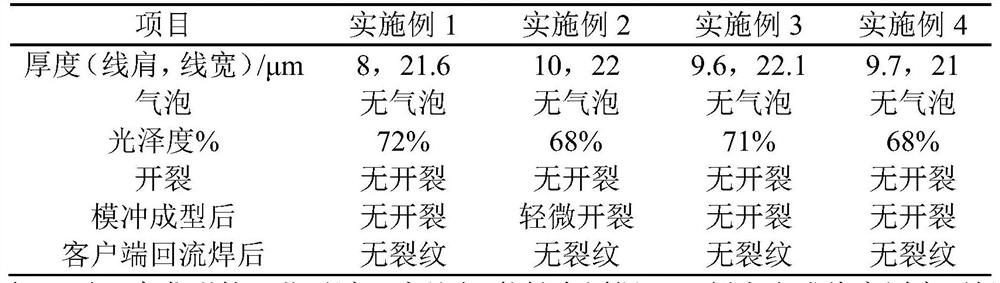

Examples

Embodiment 1

[0042]For the thick copper PCB board with a total copper thickness of 128 μm, the white solder resist ink layer is screen-printed, and the specific steps are as follows:

[0043] S1. Perform sandblasting pre-treatment on the thick copper PCB board to be screen-printed with solder resist ink, and use aluminum sheets to plug the via holes.

[0044] S2. Use 36T screen printing mesh to print white solder resist ink. Among them, the printing uses a new squeegee at 75 degrees. In addition, the white solder resist ink is used after oiling. Specifically, after oiling, stir for 17 minutes and let it stand for 30 minutes, so that the viscosity of the white solder resist ink reaches 200dpa.s, and then use it for printing.

[0045] Moreover, the angle of the screen printing squeegee for printing is 26°, and the air pressure of the screen printing is 6.2kg / cm 2 , the screen printing speed is 2.2m / min; and after the screen printing is completed, the screen frame rises, and the ink on the ...

Embodiment 2

[0050] For the thick copper PCB with a total copper thickness of 116 μm, the white solder resist ink layer is screen-printed, and the specific steps are as follows:

[0051] S1. Perform sandblasting pre-treatment on the thick copper PCB board to be screen-printed with solder resist ink, and use aluminum sheets to plug the via holes.

[0052] S2. Use 36T screen printing mesh to print white solder resist ink. Among them, the printing uses a new squeegee at 75 degrees. In addition, the white solder resist ink is used after oiling. Specifically, after oiling, stir for 20 minutes and let it stand for 30 minutes to make the viscosity of the white solder resist ink reach 185dpa.s, and then use it for printing.

[0053] Moreover, the angle of the screen printing squeegee for printing is 23°, and the air pressure of the screen printing is 6.1kg / cm 2 , the screen printing speed is 2.2m / min; and after the screen printing is completed, the screen frame rises, and the ink on the screen f...

Embodiment 3

[0058] For the thick copper PCB with a total copper thickness of 140 μm, the white solder resist ink layer is screen-printed, and the specific steps are as follows:

[0059] S1. Perform sandblasting pre-treatment on the thick copper PCB board to be screen-printed with solder resist ink, and use aluminum sheets to plug the via holes.

[0060] S2. Use 36T screen printing mesh to print white solder resist ink. Among them, the printing uses a new squeegee at 75 degrees. In addition, the white solder resist ink is used after oiling. Specifically, after oiling, stir for 15 minutes and then let it stand for 30 minutes, so that the viscosity of the white solder resist ink reaches 180dpa.s, and then use it for printing.

[0061] Moreover, the angle of the screen printing squeegee for printing is 24°, and the air pressure of the screen printing is 6.5kg / cm 2 , the screen printing speed is 2.5m / min; and after the screen printing is completed, the screen frame rises, and the ink on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com