Vertical-horizontal overall-sliding type side mold of fulcrum-few support

An overall sliding, vertical and horizontal technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of time-consuming and labor-consuming, long-term side forms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

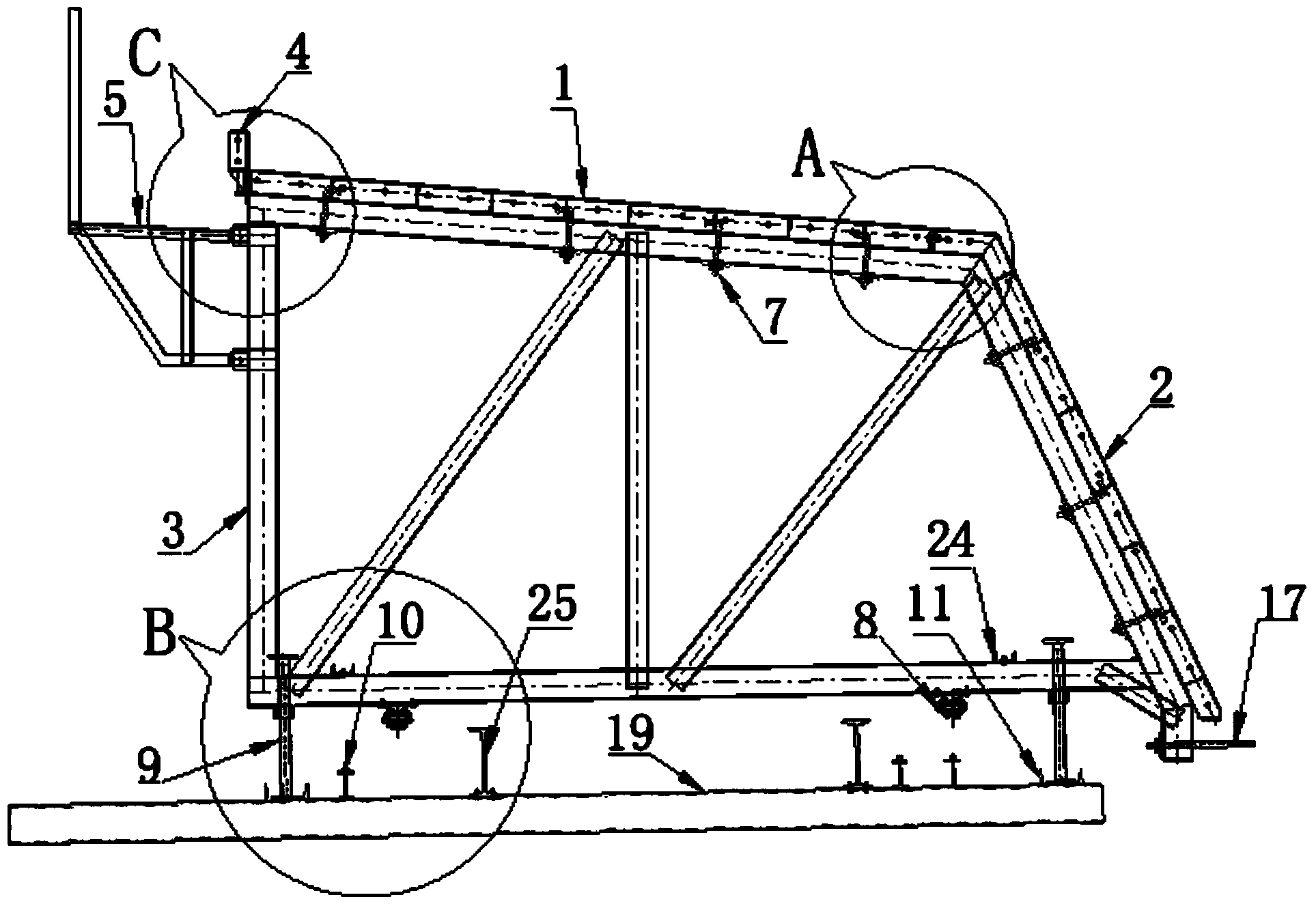

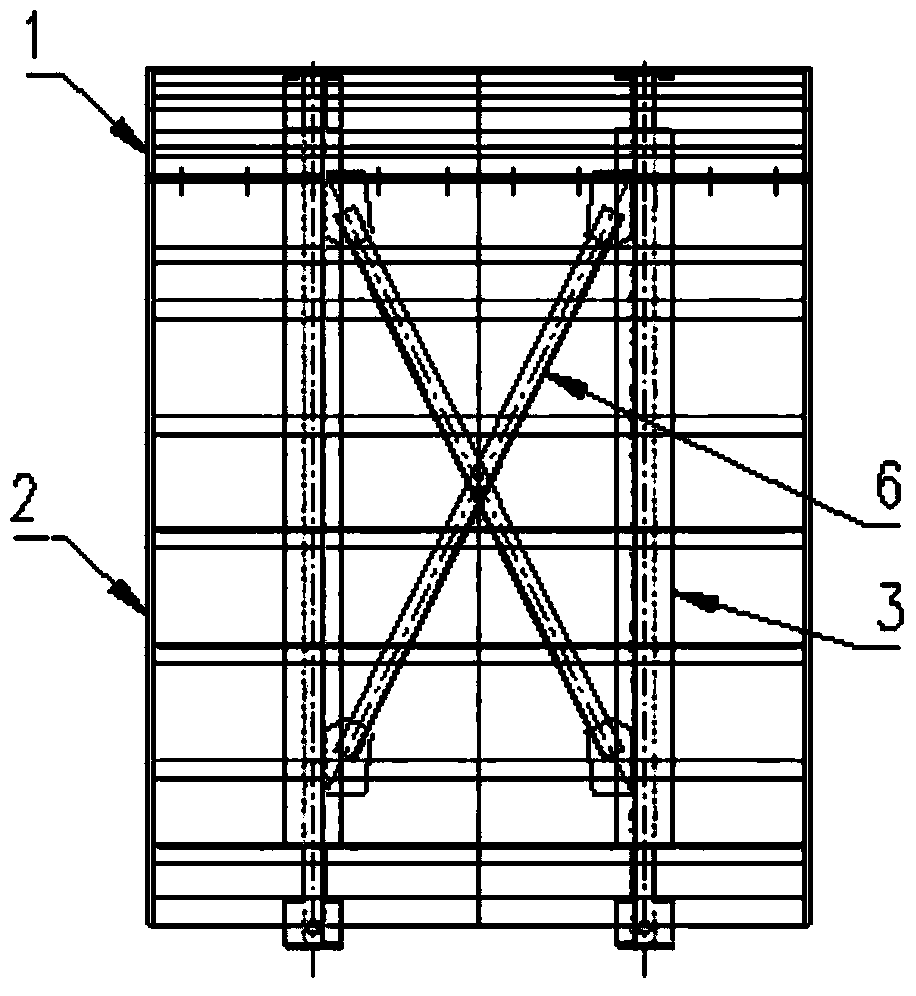

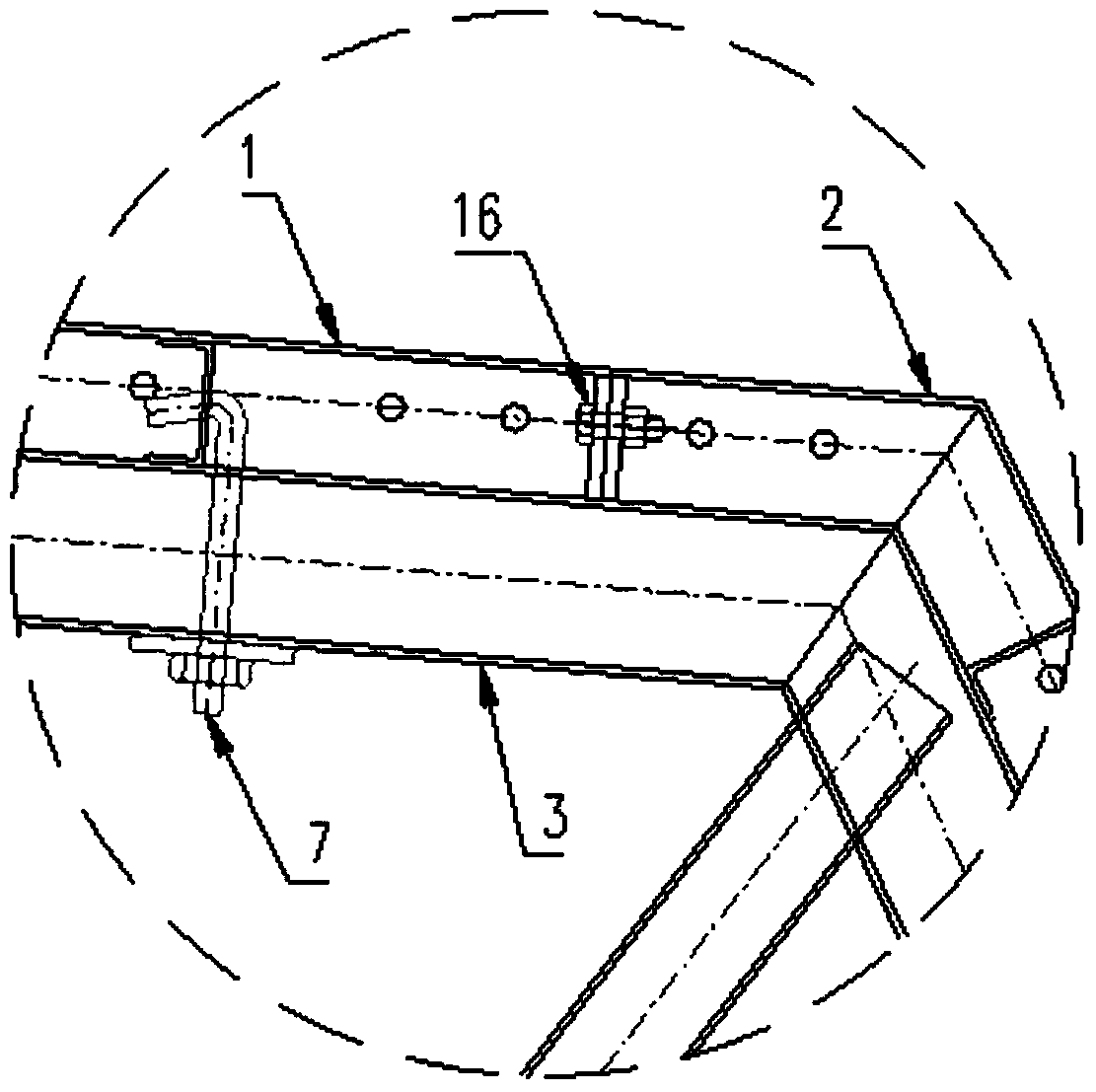

[0026] Such as Figure 1-10 As shown, the vertical and horizontal integral sliding side formwork (18) with less fulcrum support is a combined steel formwork, including flange formwork (1), web formwork (2), support truss (3), and walking rollers (8) , also includes the cantilever walkway (5), the flange baffle (4), the scissor brace (6), the hook bolt (7), the support screw (9), the pad beam (11), and the pull screw (17) , a longitudinal traction system and a transverse traction system; the flange formwork (1) and the web formwork (2) are located on two support trusses (3), and are connected to the support trusses (3) by hook bolts (7); The web formwork (2) and the flange baffle (4) are connected with the flange formwork (1) by bolts (16); ) connection; the lower end of the support truss (3) is provided with a walking roller (8) and a support screw (9); the bottom of the support screw (9) is provided with a longitudinal channel steel pad beam (11); the few fulcrums The verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com